Home » PP

PP

Material Type

Plastic

Material Full Name

Polypropylene

Process Compatibility

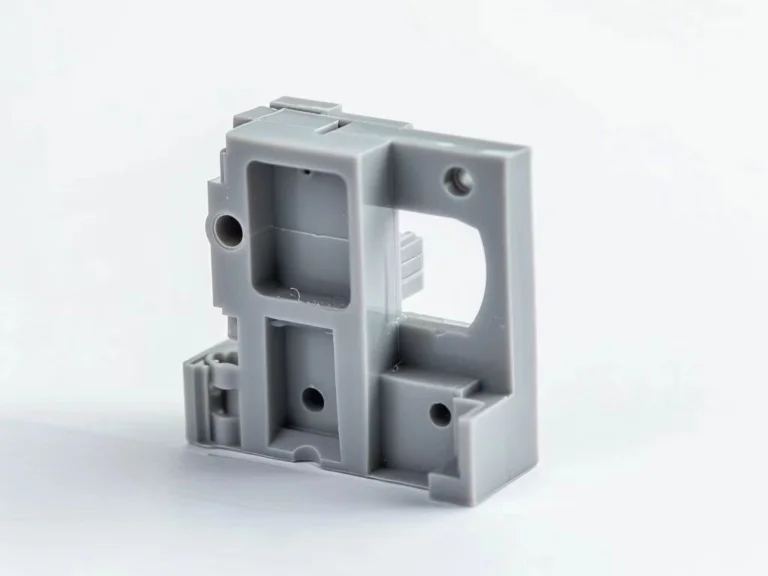

Injection Molding, CNC Machining

List of Plastic Material

List of Elastomer & Rubber Material

List of Metal Material

PP Description

Price

Strength

High chemical resistance, lightweight properties, low moisture absorption, excellent fatigue resistance, good electrical insulation.

Weakness

Susceptibility to UV degradation, poor resistance to high temperatures, tendency to warp under stress, and limited impact strength.

Common Application

PP Properties

Properties at a Glance

| Property | Metric | English |

|---|---|---|

| Density | 0.9 g/cm³ | 0.033 lb/in³ |

| Shore Hardness D | 45-55 | 45-55 |

| Min Temp. Air | -40-20°C | -40 - 68 °F |

| Max Temp. Air | 80-130 °C | 176 - 266 °F |

| UL94 Fire Rating | HB | HB |

| Elongation at Break | 8-12% | 8-12% |

Chemical Properties

- Resistant to many acids and alkalis.

- Susceptible to degradation by strong oxidizing agents and aromatic hydrocarbons.

- Generally resistant to organic solvents and oils.

How Additives Improve PP Properties

When modifying PP with additives, it's crucial to consider the specific properties you want to enhance and any potential trade-offs. For instance, adding fillers like talc or glass fibers can increase stiffness and strength but may decrease impact resistance. Similarly, incorporating flame retardants to improve fire resistance might affect the material's mechanical properties or processing characteristics.

A Comprehensive Guide For PP Injection Molding

Get PP Parts with Zhongde

Is PP recyclable?

Is PP safe?

What are the types of PP?

- Homopolymer PP: Consists of only propylene monomer units and offers good stiffness, strength, and chemical resistance.

- Copolymer PP: Contains a blend of propylene and ethylene monomer units, providing improved impact resistance and clarity compared to homopolymer PP.

- Random Copolymer PP: Incorporates ethylene randomly along the polymer chain, enhancing flexibility and impact resistance while maintaining high chemical resistance.