China Custom Plastic Parts

- All uploads are secure and confidential!

Home » Custom Products » Custom Plastic Parts

Custom plastic parts are widely used in many industries, which have different requirements for precision and quality. As a family enterprise with more than 40 years of history, Zhongde has accumulated rich experience and has become one of the leading custom plastic parts manufacturers in China.

Whether your custom plastic pieces used in aerospace require high precision, or only daily necessities requiring a beautiful appearance, we can always provide you with molded plastic products that meet your highest expectations at affordable prices. To order custom plastic parts, let’s start with a free quotation!

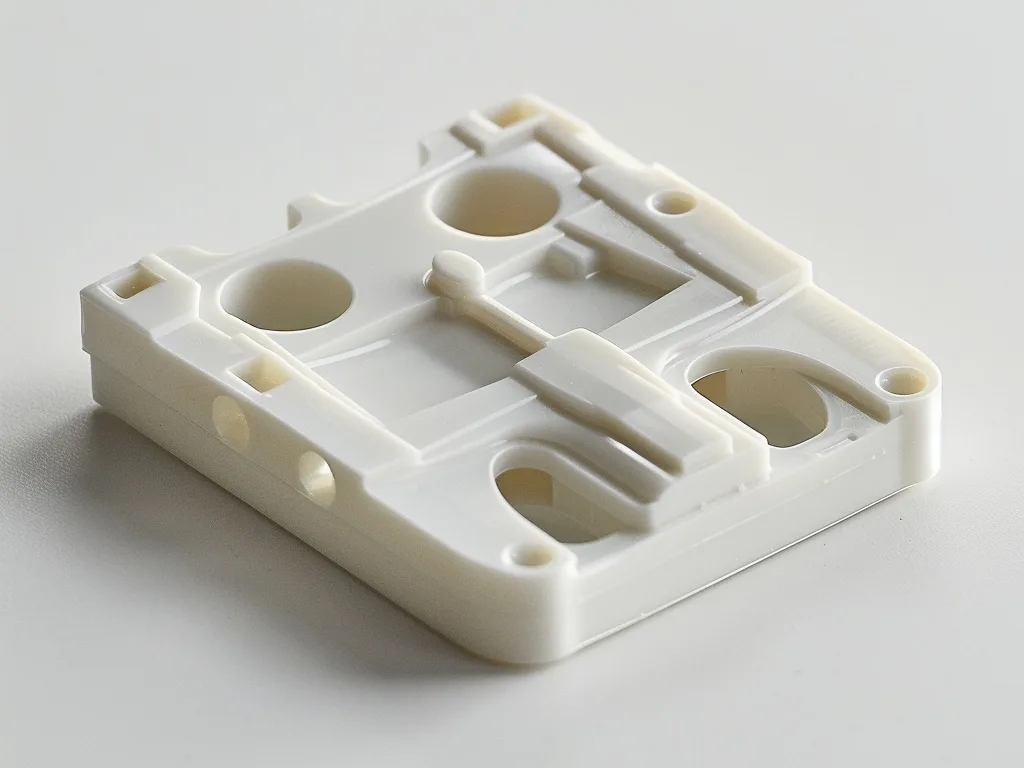

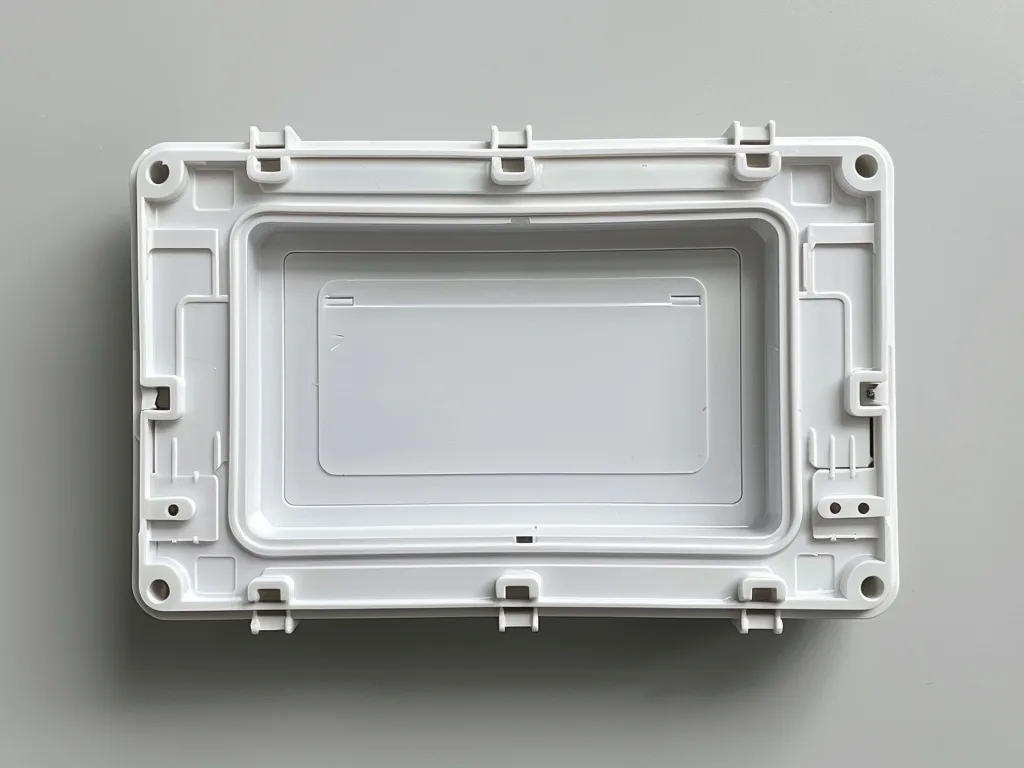

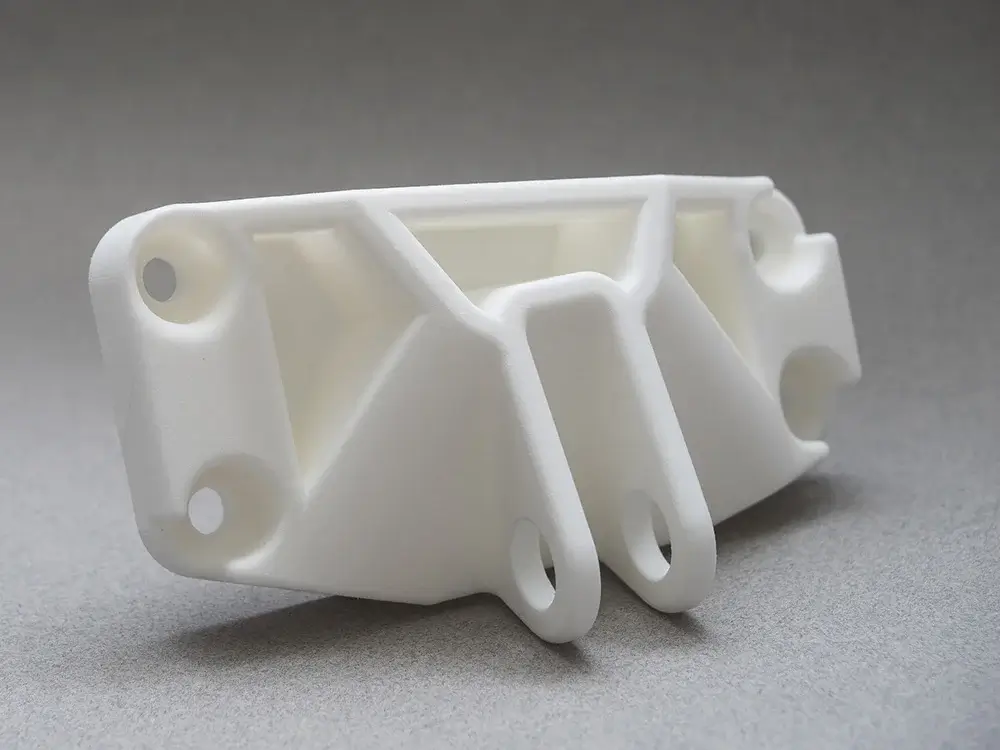

Custom Made Plastic Parts Display

As a plastic parts supplier, Zhongde can produce custom plastic pieces by plastic injection molding, overmolding, insert molding and CNC machining. Click the following link and view our previous custom plastic products.

China Custom Plastic Components Specifications

| Name | Description |

|---|---|

| Maximum Size | 2000x1500x1000mm |

| Color | White, Black, Transparent, or according to Pantone No. |

| Tolerance | ±0.05mm |

| Surface Finishing | Glossy, Semi-gloss, Matte, Textured finish, As-machined |

| Addictives | UV absorbers, Flame retardants, Plasticizers, Colorants, Carbon fibers, Glass fibers |

| Logo | Debossed, Embossed, Printing |

| Drawing Format | 2D Drawing: PDF/JPG/PNG. 3D Drawing: STEP/STP/IGS/DXF/DWG |

China Custom Plastic Parts Materials

We provide one-stop plastic parts custom solution. Our high quality plastic parts are produced with high-grade resin. Following are some of the most common plastic materials we use. As plastic parts manufacturers, we can also provide material modification services to meet unique requirements. If you need special material, kindly send us email to sales@zdcpu.com

POM

LDPE

HDPE

UHMWPE

PTFE

PC

PMMA

PVC

ABS

PP

PA

Why Choose Zhongde as Your Custom Plastic Parts Manufacturer

Professional customized plastic parts supplier with 40 years of manufacturing experience.

- ISO 9001:2015 Certified, strict QC system to ensure quality.

- China based plastic parts maker factory with competitive price.

- Making molds in-house easy to avoid production default

How do I order custom plastic parts from you?

Click get a quote to get an accurate quotation, our custom services will offer you a guideline in details.

How to make custom plastic parts?

The process of how to get plastic parts made involves four basic steps: come up with a design, decide manufacturing process, build a prototype, and then production.

My customized plastic parts are used in a special environment, how do you ensure that they can meet my requirements?

We have experienced material engineers who will choose the right material according to the product's use environment. If the general material cannot meet the requirements, we will add additives or modify the plastic raw materials.

It is easy to fill the form.

Better Quality, Faster Delivery

Upload your design drawing and all uploads are secure and confidential!

Knowledge Hubs

Causes and Prevention of Whitening Phenomenon in PVC Product

Have you ever noticed a whitening phenomenon in PVC product whitening? Some of your transparent PVC products, like shower curtains

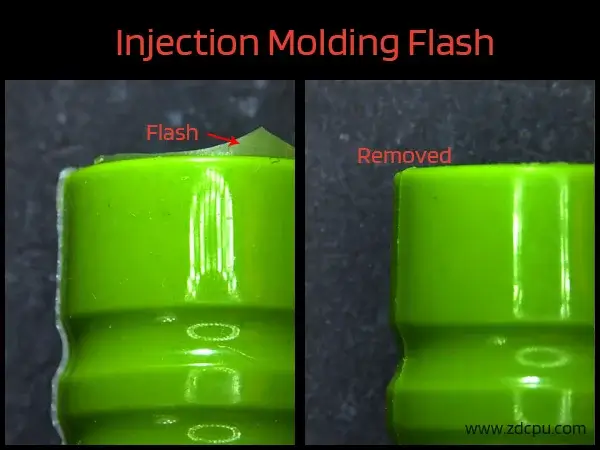

Dealing with Injection Molding Flash: Causes, Prevention, and Removal

An injection molding flash occurs when molten plastic escapes the mold and solidifies. It is a common injection molding defect.

Principle of Injection Molding Process

The Working Principle of Injection Molding Machine The injection molding principle is that the plastic is heated and melted in