A Complete Standard CNC Machining Tolerances Guide

CNC machining tolerances are an important parameter when manufacturing products, and most industrial and consumer products require consistency to meet manufacturing standards. Selecting the right

Home » Medical Equipment Custom Molding

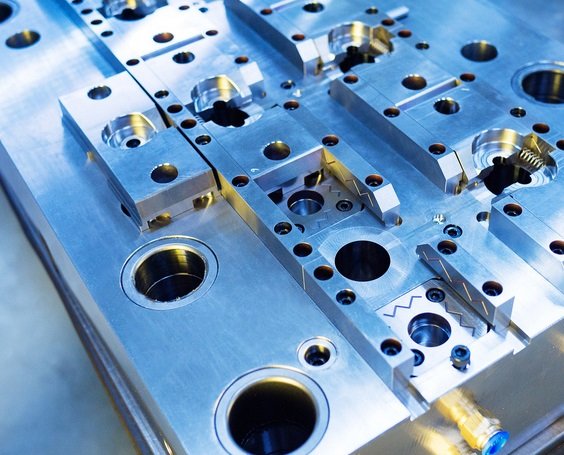

Zhongde one of the top medical molding companies, the source of assistance in the design and development of non-implantable moulding medical such as, rubber medical handles and devices. Zhongde has extensive experience in working with medical plastic injection molding and medical silicone molding, particularly in bonding silicone to metal substrates: aluminum, stainless steel, and anodized metals. Zhongde can provide support in medical device injection molding.

The medical industry requires exacting lot traceability and quality standards at the highest level. Zhongde as custom plastic parts manufacturers is able to deliver consistently and respond quickly to the unpredictable demand that often occurs in the medical industry.

Industry Expertise

Flexible Customization

Collaorative Approach

A Complete Standard CNC Machining Tolerances Guide

CNC machining tolerances are an important parameter when manufacturing products, and most industrial and consumer products require consistency to meet manufacturing standards. Selecting the right

Why Do We Have to Test the Mold?

Most of the defects of molded products are caused in the plasticization and injection stages, but sometimes they are also related to improper mold tool

Principle of Injection Molding Process

The Working Principle of Injection Molding The injection molding working principle is that the plastic is heated and melted in the heating barrel of the

Contact with us!

Get Your Parts in Higher Quality, Faster Delivery!

Email Us: sales@zdcpu.com