The Overview of Two-shot Molding vs Overmolding

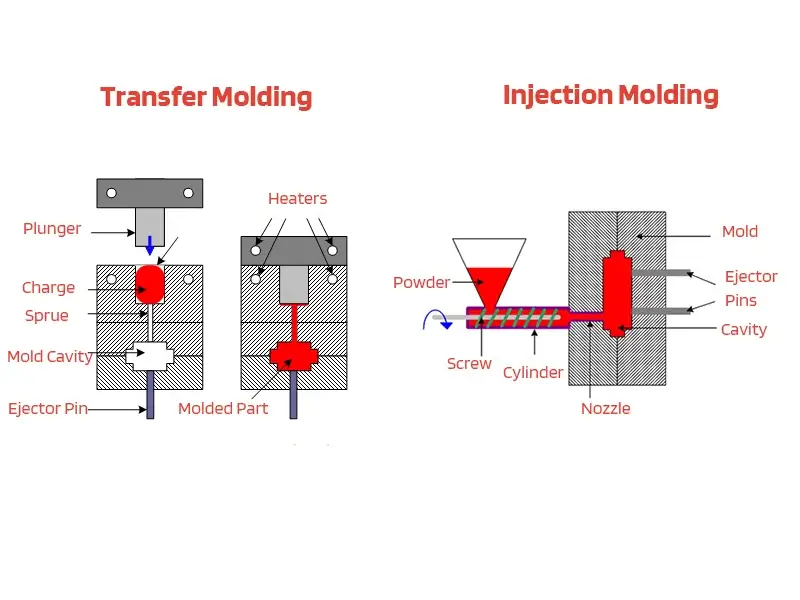

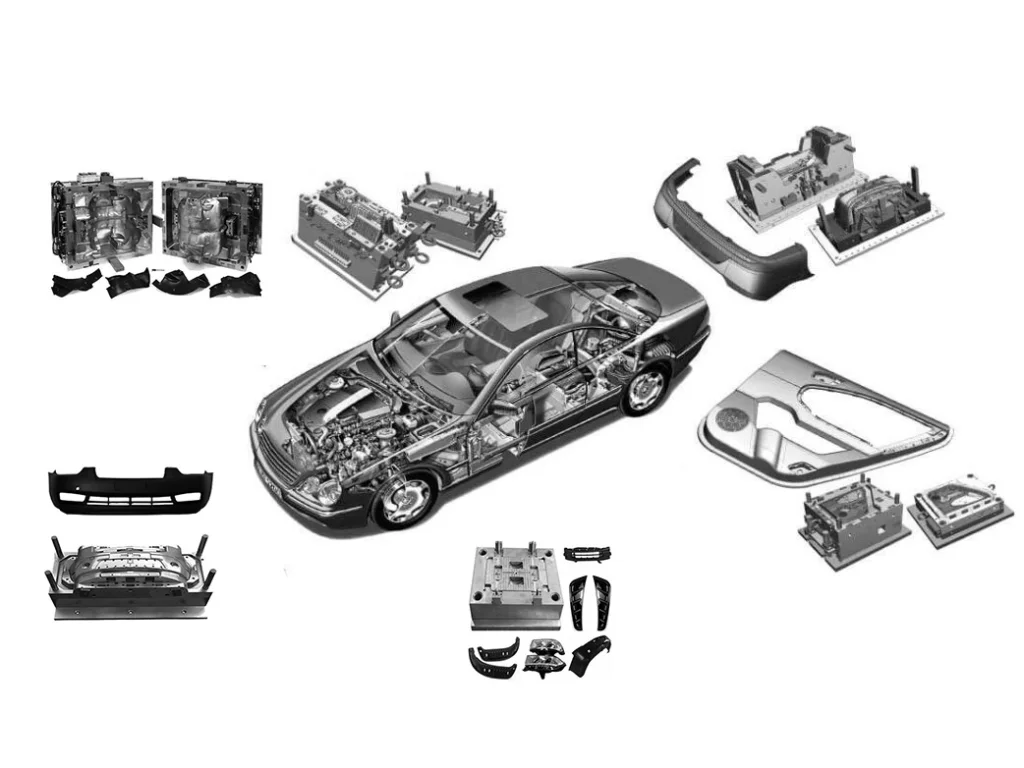

Two-shot molding vs overmolding, are two different molding types with unique advantages to meet different design needs for custom components production. Injection molding is a widely used modern manufacturing, serving as a versatile and efficient method for producing a wide range of plastic parts across numerous industries. There are many different injection molding types. By […]

The Overview of Two-shot Molding vs Overmolding Read More »