China Custom CNC Machining Parts

- All uploads are secure and confidential!

Home » Custom Products » CNC Machining Parts

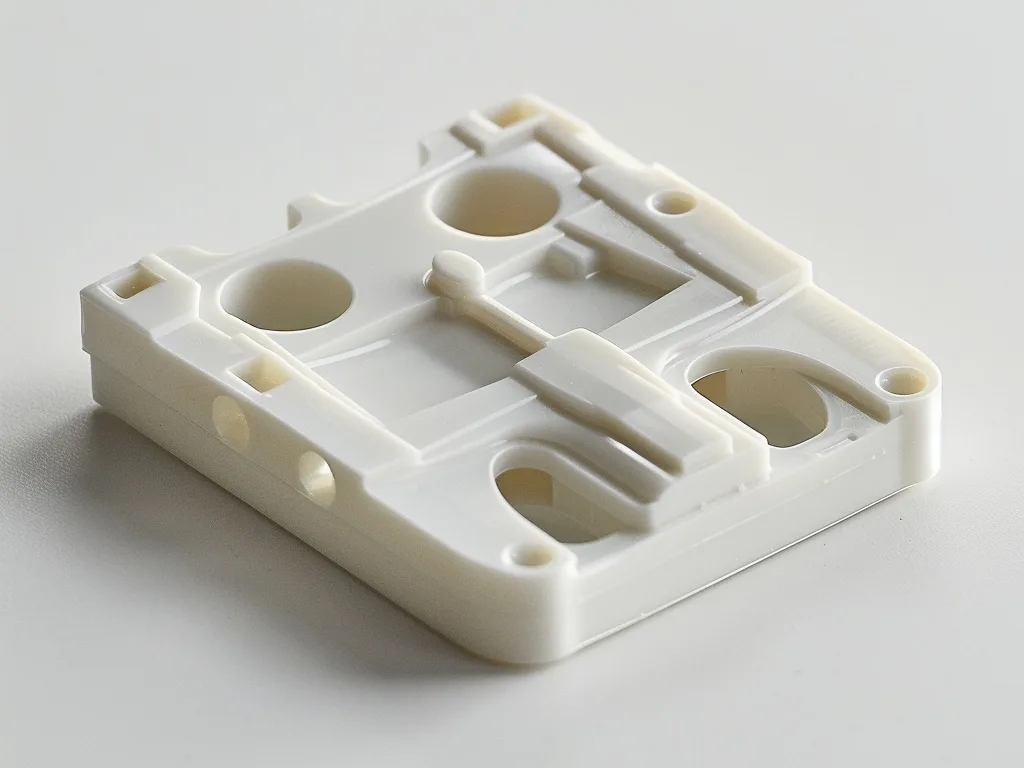

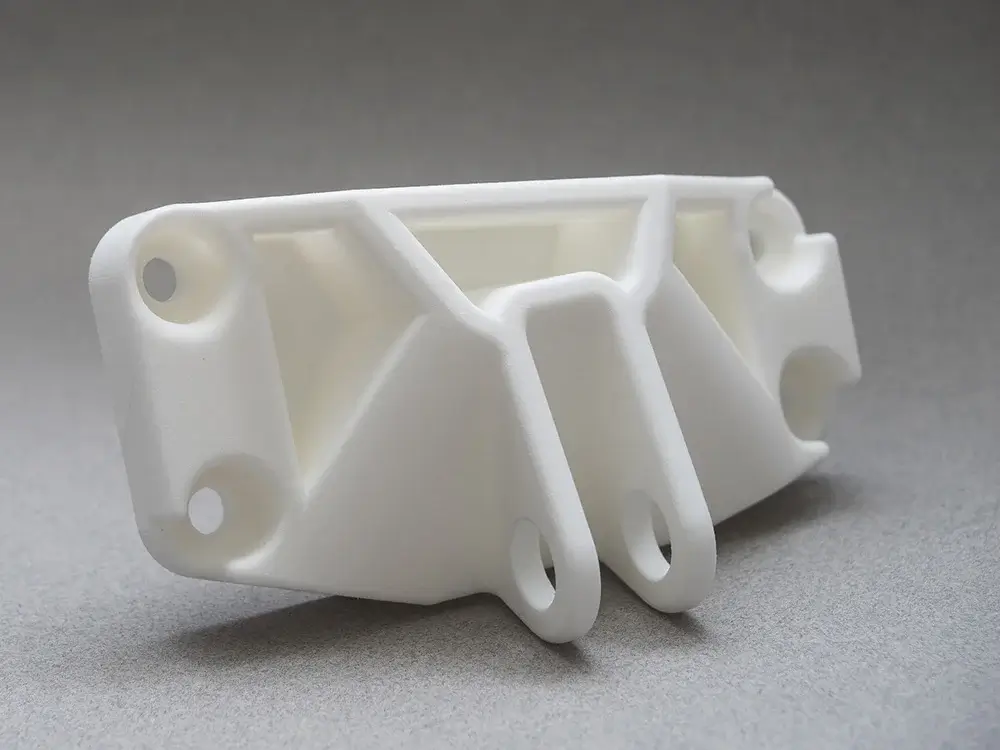

Zhongde, being professional custom China precision CNC milling parts and China CNC turning parts company in China, has introduced more than 100 sets of advanced CNC machining equipment, which can efficiently complete the production of a large number of China CNC machined plastic parts and China CNC metal parts, providing precision CNC machined components by our Chinese factory.

At the same time, it can ensure that all custom China CNC machined parts produced are of high precision and high quality, and can be customized according to customer needs. The precision machined parts we produce are mainly divided into two categories: custom CNC plastic machined parts and China machined metal parts. Please continue browsing to find products that match your needs.

China Custom Machining Parts Types

China Custom CNC Machining Parts Specifications

| Name | Description |

|---|---|

| Maximum Size | 1500x1500x1000mm |

| Color | White, Black, Transparent, or according to Pantone No. |

| Tolerance | ±0.05mm |

| Surface Finishing | Glossy, Semi-gloss, Matte, Textured finish, As-machined |

| Addictives | UV absorbers, Flame retardants, Plasticizers, Colorants, Carbon fibers, Glass fibers |

| Logo | Debossed, Embossed, Printing |

| Drawing Format | 2D Drawing: PDF/JPG/PNG. 3D Drawing: STEP/STP/IGS/DXF/DWG |

Why Choose Zhongde as Custom CNC Machining Parts Supplier

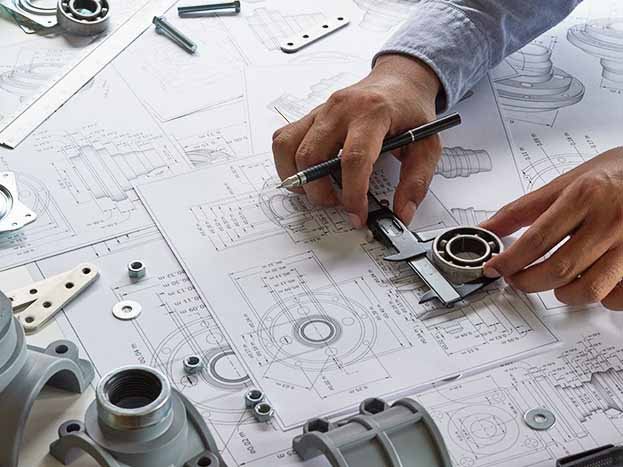

Advanced In-house Equipment

Experienced Technical Team Support

Stable and Durable Quality

CNC Machining Parts Manufacturing Process

Step 1

Step 2

Step 3

Step 4

Available Material of China Custom CNC Machining Parts

Copper

Carbon Steel

Stainless Steel

Aluminum

PMMA

PTFE

UHMWPE

POM

PA

How can I start to customize my CNC products?

What is your tolerance in CNC machining?

What is the difference between cnc machining and injection molding?

Knowledge Hubs

A Comprehensive Guide for Injection Mold Grades and Types

Injection molding is a widely used manufacturing process and it is responsible for crafting a wide range of plastic products

Introduction to Injection Molding Tolerances and How to Optimize Them

Injection molding is a common way of manufacturing high-quality, precisely crafted plastic parts. However, achieving precise and consistent tolerances can

Minimizing Injection Molding Deformation: Strategies for High-Quality Products

Injection molding deformation is a critical challenge in the manufacturing process for producing complex plastic parts with precision and efficiency.