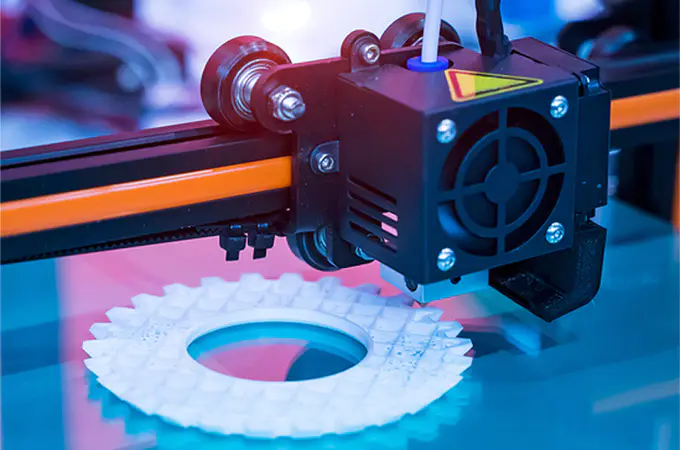

FDM 3D Printing Service

Zhongde provides rapid prototyping and low-volume on-demand production with FDM 3D printing service.

Upload your CAD file to get instant quotes on FDM 3D printed parts.

- All uploads are secure and confidential

What Is FDM 3D Printing?

In the context of 3D printing, FDM (fused deposition modeling) is a popular additive manufacturing technique. FDM 3D printing builds custom parts by heating and extruding thermoplastics layer-by-layer. It is a good option for rapid prototypes and low-volume on-demand manufacturing end-use parts. Material options include popular thermoplastics like ABS, TPU, PEI, PETG, and more. Get an instant quote for FDM parts.

Size of FDM 3D Printed Parts

The below table shows the size of the Fused Deposition Modeling FDM 3D printed parts we usually make. If you need a larger size, we can also help you achieve it.

| Name | Description |

|---|---|

| Requirement | Specification |

| Max Build Size | 500x500x500mm(19.68"x19.68"x19.68") |

| Standard Lead Time | 4 business days |

| Dimensional Accuracy | ± 0.5% with a lower limit of ± 0.5 mm (± 0.0196”) |

| Layer Height | 100-300μm |

| Infill | 20-100% |

*The maximum build size for Carbon-filled Nylon (Onyx) is 320 mm x 132 mm x 154 mm

Available Material of FDM 3D Printing

Metals

- Aluminum

- Cobalt Chrome

- Inconel

- Stainless Steel

Plastics

- ABS

- PA(Nylon)

- Polycarbonate

- Polypropylene

Elastomers

- TPU

- Silicone

* These materials are available by contacting sales@zdcpu.com.

FDM 3D Printing Design Guidelines

The following table summarizes the recommended and technically feasible values for the most common features encountered in FDM 3D printed parts.

| Feature | Recommended Size |

|---|---|

| Unsuported Walls | 0.88mm(0.0315") |

| Supported Walls | 0.88mm(0.0315") |

| Minimum Feature Size | 2.0mm(0.0787") |

| Minimum Hole Diameter | 2.0mm(0.0787") |

Custom Products

Service

Surface Finishing for 3D Printing

| Name | Description | Materail Compatibility | Color | Texture | |

|---|---|---|---|---|---|

|

Painting | Choose from a wide range of paints and coatings that can achieve the desired look and feel. | Plastics and metals | RAL or Pantone code | Gloss, semi-gloss, flat, metallic, textured |

|

Polishing | Achieve a smooth and glossy surface finish through mechanical polishing techniques. This process removes layer lines and imperfections, resulting in a refined appearance. | Plastics (PLA, ABS) | Raw material | Smooth and glossy |

|

Powder Coating | Apply a durable and protective powder coating to your 3D-printed part. This process involves electrostatic-ally applying a fine powder, which is then cured to create a tough and resistant finish | Metals (Alumium, stainless steel, steel) | Standard and custom options | Gloss or semi-gloss |

|

Bead Blasting | Utilize bead blasting to achieve a uniform and textured surface finish. This process involves propelling small abrasive particles at the surface of the object. | Metals and plastics | N/A | Matte or satin-like |

Related Products of Fused Deposition Modeling

Related Services of Fused Deposition Modeling

Overmolding & Insert Molding

Selective Laser Sintering

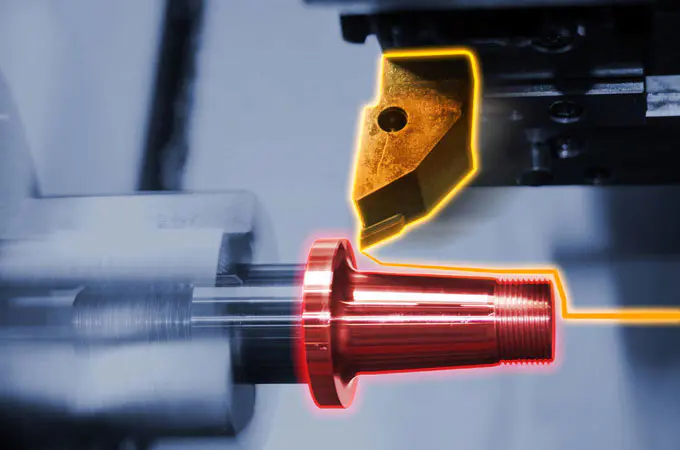

CNC Turning

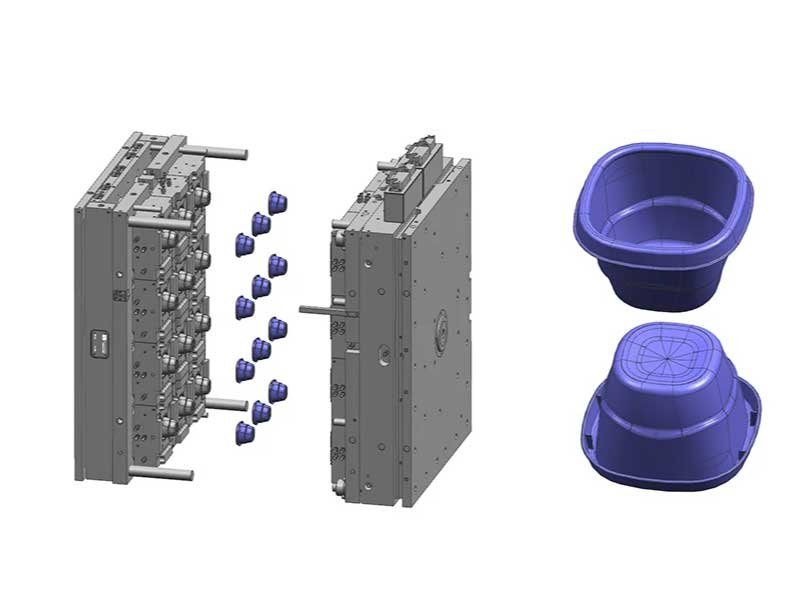

Plastic Injection Molding

Rubber Injection Molding

CNC Milling

Knowledge Hubs

Dealing with Injection Molding Burn Marks

Injection molding burn marks are a common defect in the realm of injection molding. These burn marks not only influence

Thin Wall Injection Molding: Definition, Design, and Troubleshooting Guide

Thin Wall Injection Molding has gained significant traction in the fast-paced world of manufacturing due to the ever-increasing demand for

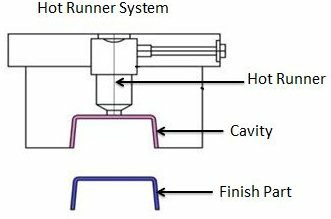

The Ultimate Guide to Hot Runner Systems and Enhanced Product Quality

Hot runner systems originated from non-runner systems in the injection molding industry. As an advanced plastic injection molding technology, its