On-Demand Manufacturing Services

Zhongde is dedicated to offering the finest in rapid prototyping and on-demand production services. Upload your CAD file for a free analysis and quotation.

- All uploads are secure and confidential!

Home » Service

Zhongde On-Demand Manufacturing Services

Injection Molding

Compression Molding

Cast Molding

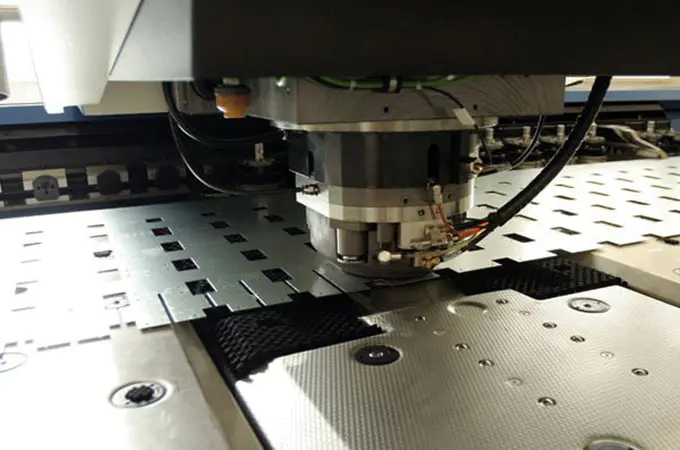

Metal Stamping

CNC Machining

3D Printing

Additional Service

Material Selection

Surface Finishing

Assembly & Packing

Material Diversity: choose from 100+ kinds of materials

Custom Process

Your one-stop on-demand manufacturer. We help realize your ideas from design to end-use products and make delivery directly to your hands. Start from uploading drawings now.

Upload Part Design

Confirm Specifications

Rapid Prototype and Review

Mass Production

Delivery

Testimonials

They took the time to elaborate on the processand followed up with me quickly every time. have the utmost faith in their integrity and workethic. As with any transaction internationally it isimportant to be patient and ensure that youunderstand the process. They took time to makesure that the relationship was put first and I lookforward to continuing to work with them!

Kevin Sonderegger From US

Great customer service. very fast hassle-freeshipping. The product was what I need and bettethan expected. will definitely order from them again.

Bob Fenner From US

Fantastic company. very professional staff. Theygave me suggestion on perfecting my designAccelerated production helped me launch myproduct to the market promptly.

Paul Sandford From UK

It is easy to fill the form.

Better Quality, Faster Delivery

Upload your design drawing and all uploads are secure and confidential!

Knowledge Hub

The Overview of Two-shot Molding vs Overmolding

Two-shot molding vs overmolding, are two different molding types with unique advantages to meet different design needs for custom components

Causes, Prevention, and Solutions for Ejector Pin Marks

Ejector pin marks are common defects in injection molding processes and significantly impact the quality and appearance of molded parts.

Plastic Injection Molding Defect-Brittleness in Injection Molding

Brittleness in injection molding is a common plastic injection molding defect. It refers to the tendency of a molded plastic