CNC Machining Serivce

On-demand CNC machining for rapid prototyping and production parts. Get a quote for a custom CNC machining service.

- CNC Milling

- CNC Turning

- All uploads are secure and confidential!

Get a Quote

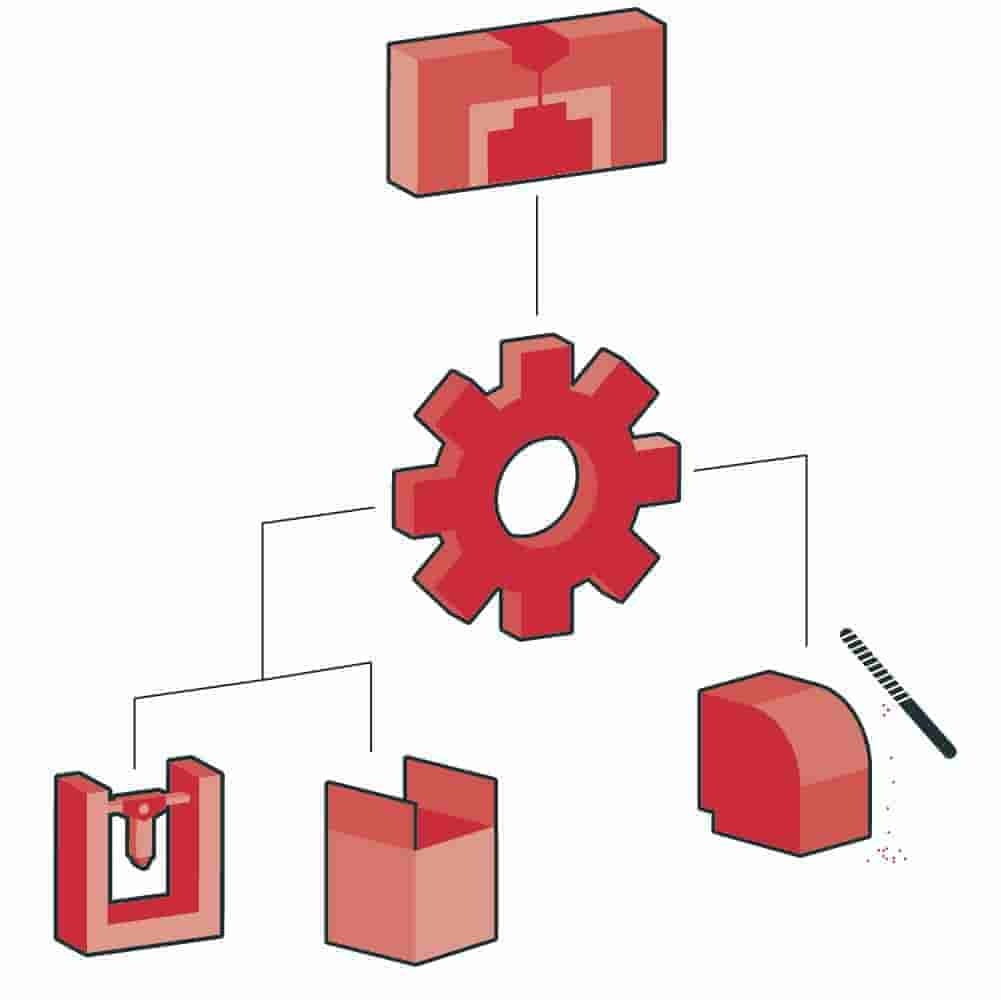

DFM

Tool Making

Sample Test

Production & QC

Delivery

Zhongde CNC Machining Process

CNC Milling Service

CNC Turning Service

CNC Machining Materials

The general plastic CNC machining materials are listed below:

- ABS

- PP/Polypropylene

- Nylon6

- POM/Delrin

- PVC

- LDPE

- HDPE

- UHMWPE

- PC/Polycarlonate

- PTFE

The general metal CNC machining materials are listed below:

- Aluminum

- Copper

- Stainless

- Brass Steel

- Carbon Steel

- Steel Alloy

CNC Machining Surface Finishing

| Finishing | Description | Material Compatibility | Color | Link | |

|---|---|---|---|---|---|

|

As Machined | For as machined all sharp edges are removed and parts are deburred. Tool marks are visible. | All plastics and metals | Uniform of raw material color | Learn More |

|

Smoothing | A finishing CNC machining operation can be applied to the part to reduce its surface roughness. Machine marks are less evident but still visible. | All plastics and metals | Uniform matte of raw material color | Learn More |

|

Bead Blasting | Bead blasting adds a uniform matte or satin surface finish on a machined part, removing the tool marks. | All metals | Uniform matte of raw material color | Learn More |

|

Powder Coating | Powder coating compatible with all metal materials and can be combined with a bead blasting to create parts with smooth and uniform surfaces and excellent corrosion resistance. | All metals | Black or any RAL or Pantone code | Learn More |

|

Black Oxide | Black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection. | Stainless steel and copper alloys | Black | Learn More |

|

Electropolishing | An electrochemical process used to polish, passivate and deburr metal parts. It is useful to reduce surface roughness. | All metals | Natural metal color | Learn More |

Our Quality Promise

Zhongde is committed to providing quality products that meet or exceed the needs of our customers through continuous improvement.

Strictly follow the confirmed drawings or samples to produce. If there is any deviation, our company will replenish to our customers to make up for the loss.

What is CNC Machining

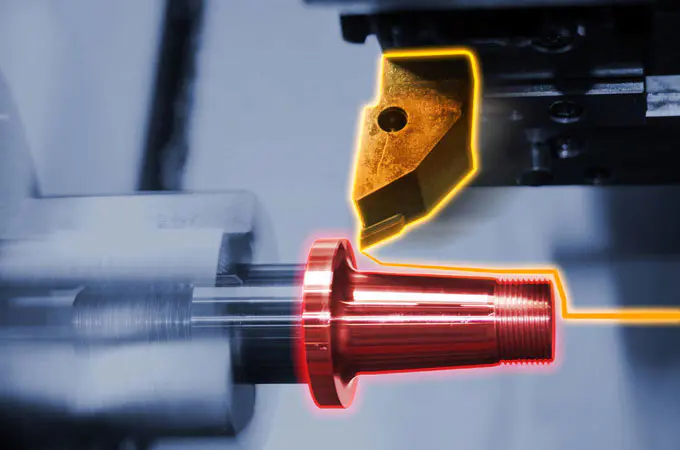

CNC machining, or computer numerical control machining, refers to the manufacturing process of changing the dimensions or performance of the workpiece through automated, high-speed cutting tools.

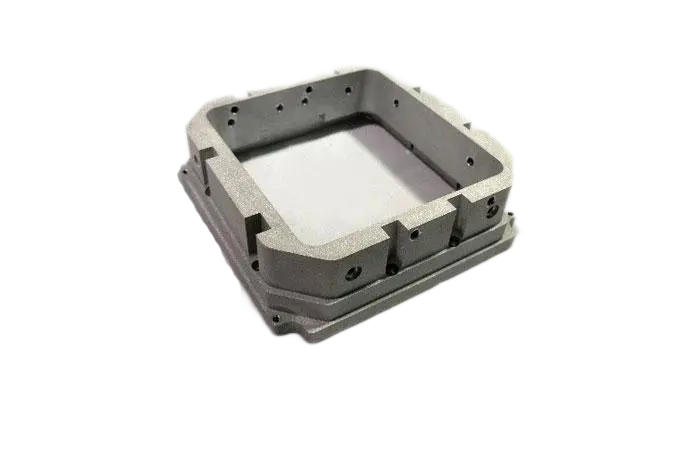

Zhongde, a reputable fast CNC machining company in China, supplies high-quality 3D customized precision CNC machining services, including CNC milling and CNC turning. Our CNC turning service with 3-axis, full 5-axis machines. Different machining methods ensure the provision of high accuracy and quality custom-machined parts at a competitive price.

Advantages of Custom CNC Machining

Small Production Run

CNC machines can manufacture one or multiple samples from the same design, opening the door to batch-process manufacturing.

Quick Turnaround Times

With advanced CNC machines, the manufacturing speed of different types of high-quality CNC machining parts is accelerated.

Fully Automatic Production

Computers are used to control the machines, the process is automated therefore increasing speed and quality of manufacturing.

Easy to Process Large Size Part

CNC machines create outputs that cannot be reproduced by manual machines when used in tandem with advanced design software. The machines can produce a variety of sizes, textures and shapes.

High Precison Production with Small Tolerance

Zhongde, a reputable fast CNC molding and machining company with its own factory, shows greater dimensional accuracy. In terms of its tighter tolerance, even ±0.025mm tolerance can be achieved.

Types of CNC Operations

| Types | Description |

|---|---|

| CNC Milling | Milling is mainly used for rough machining and semi-finish machining of various planes, various grooves, etc. |

| CNC Turning | Turning is method of cutting the rotating surface of workpiece on a lathe with a turning tool. |

| CNC Drilling | Drilling refers to the method used to machine holes. The drilling tool moves relative to the workpiece and feeds axially. |

| CNC Planing | Planning is a method of cutting on a planing machine using a planer and is mainly used to process straight-shaped surfaces. |

| CNC Grinding | Grinding is mainly used for finishing the inner and other cylindrical surfaces, inner and outer conical surfaces, and planes, and forming surfaces of parts to obtain higher dimensional accuracy and smaller surface roughness |

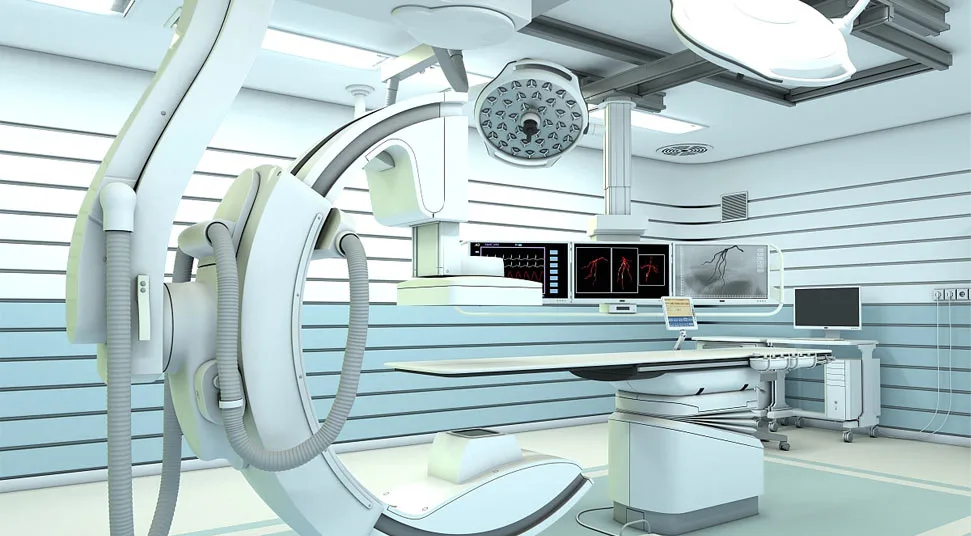

Applications of CNC Machining

Why Choose Zhongde for CNC Machining

Cost Effective

Consistency and High Quality

Proven Success

Complete Range of Service

Start A New Project Right Now!

FAQs of CNC Machining Services

What is the maximum size of parts that can be machined?

What level of precision can CNC machining achieve?

What is the typical turnaround time for CNC machined parts?

Knowledge Hubs

A Comprehensive Guide For ABS Injection Molding

ABS Injection Molding ABS injection molding is a versatile and widely used manufacturing process, utilizing Acrylonitrile Butadiene Styrene (ABS) as

Factors Affecting the Price of Automotive Molds Processing

Due to the various advantages of injection molds, many manufacturers also like to use them, but different types of products

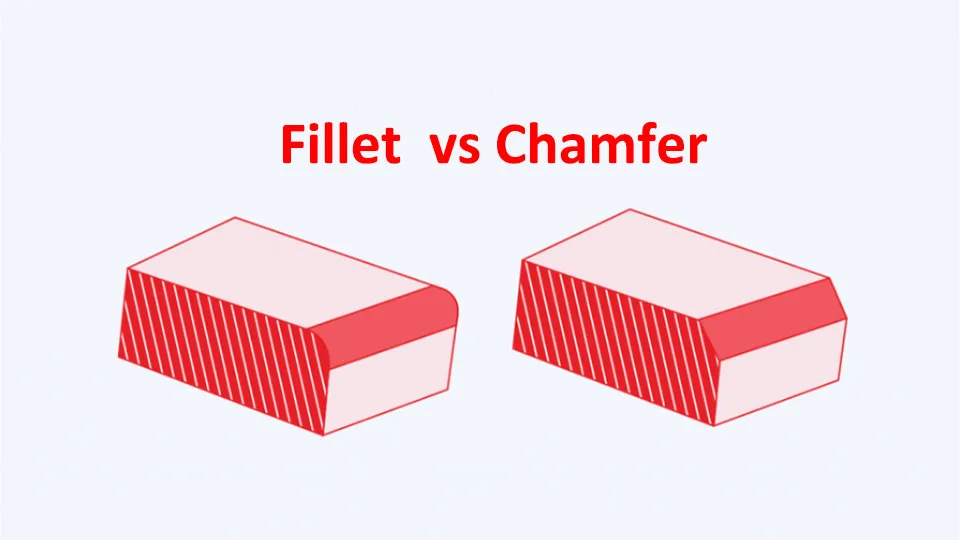

Fillet and Chamfer: What Are the Differences and Uses?

Fillets and chamfers are two ways to design the edges where two surfaces of a part meet. Both fillets and