China Custom Rubber Parts

- All uploads are secure and confidential!

Home » Custom Products » Custom Rubber Parts

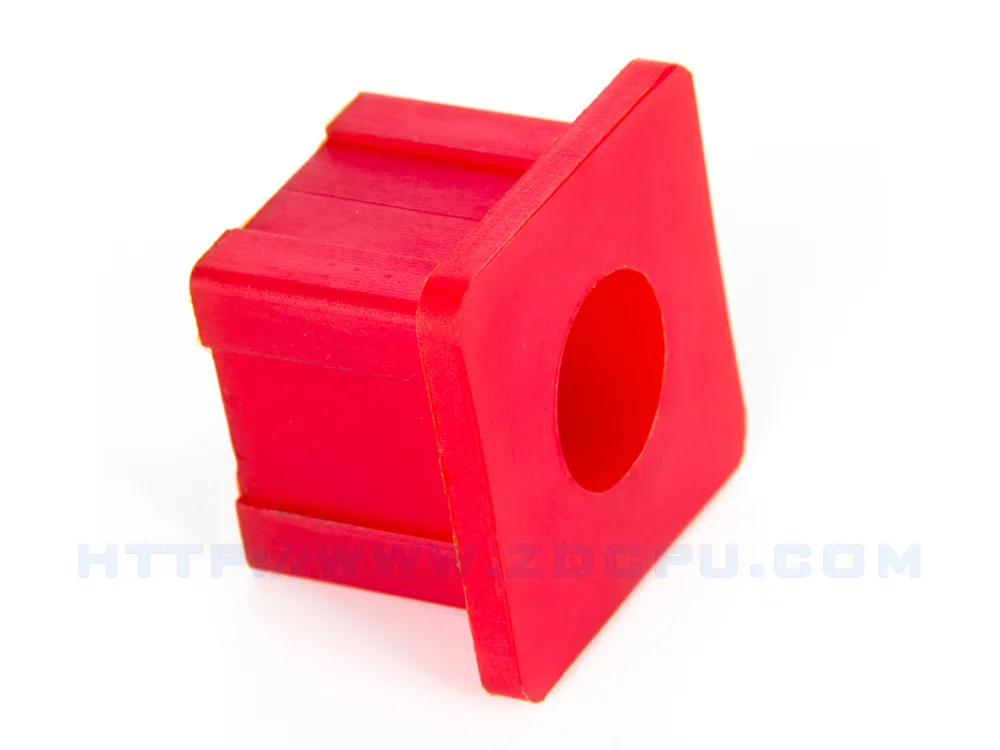

With years of experience in manufacturing industrial molded rubber products, Zhongde has become a professional OEM rubber parts manufacturer. We introduced rubber injection machines and automatic machines for high-volume orders and large vulcanized machines for big rubber pieces. Being one of the top firm custom rubber product manufacturers, With all the advanced machines, we can produce a wide range of compression molded parts, including OEM rubber parts, pure rubber parts, rubber bonding metal parts, rubber bonding plastic parts, and fabric reinforced rubber parts.

Types of Custom Rubber Parts

Specification of Custom Rubber Parts

| Name | Description |

|---|---|

| Maximum Size | 1500x1500x1000mm |

| Color | White, Black, Transparent, or according to Pantone No. |

| Tolerance | ±0.05mm |

| Surface Finishing | Glossy, Semi-gloss, Matte, Textured finish, As-machined |

| Addictives | UV absorbers, Flame retardants, Plasticizers, Colorants, Carbon fibers, Glass fibers |

| Logo | Debossed, Embossed, Printing |

| Drawing Format | 2D Drawing: PDF/JPG/PNG. 3D Drawing: STEP/STP/IGS/DXF/DWG |

Available Material for Custom Rubber Parts

NR

NBR

SBR

CR

EPDM

VMQ

FKM

IIR

PU

Why Choose Zhongde Rubber Molded Parts Manufacturers

My rubber parts are used in a special environment, how do you ensure that they can meet my requirements?

We have experienced material engineers who will choose the right material according to the product's use environment. If the general material cannot meet the requirements, we will add additives or modify the rubber raw materials.

How can I start to customize my rubber products?

You can send us samples or 2d / 3d drawings, and we will produce accordingly.

What is your monthly output of rubber parts?

Our monthly output of rubber parts can reach to 1,000,000pcs.

What is silicone rubber parts used for?

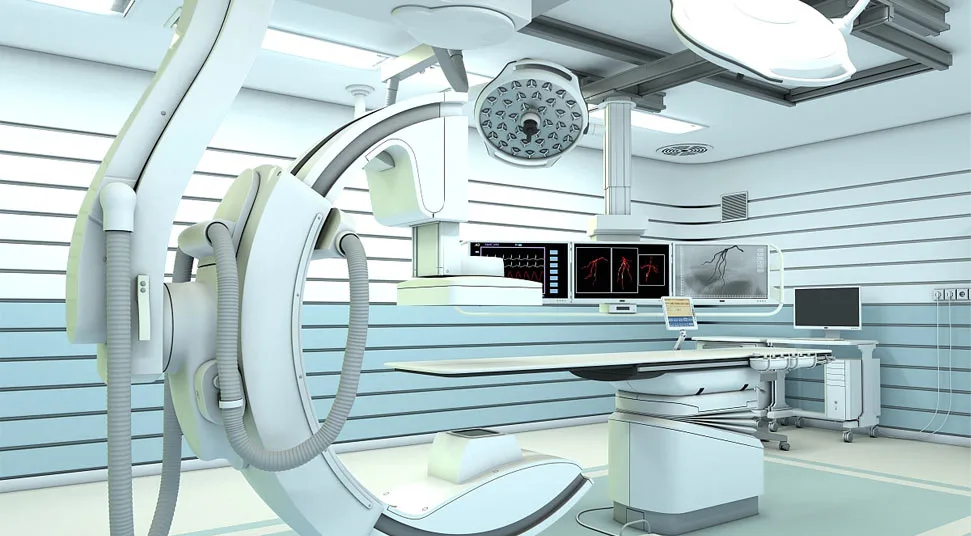

Silicone rubber parts can be custom in any shapes, widely used in electronics, medical industry, automotive and more.

It is easy to fill the form.

Better Quality, Faster Delivery

Upload your design drawing and all uploads are secure and confidential!