Custom Molding Parts Applications

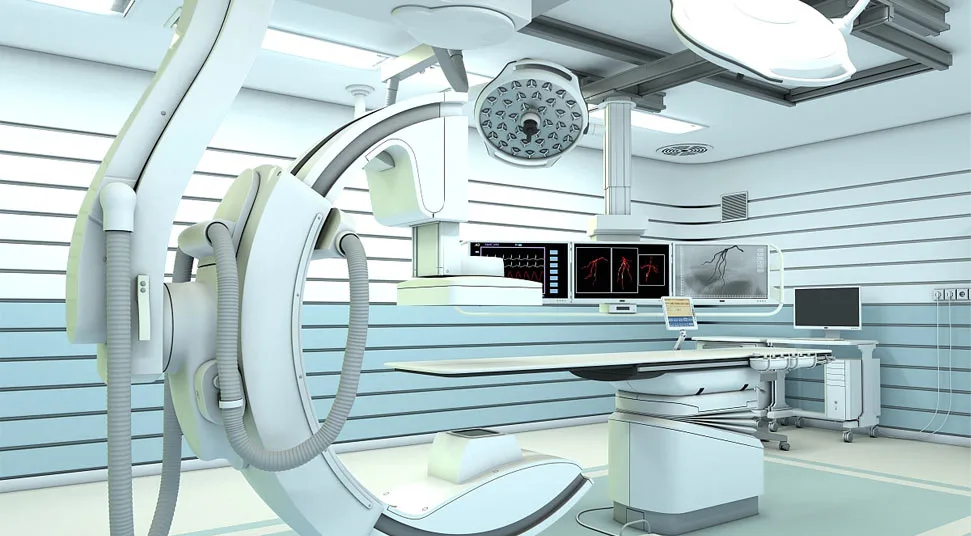

Medical Equipment Custom Molding

On-demand Manufacturing of Medical Plastic & Silicon Parts Molding Zhongde one of the top medical molding companies, the source of assistance in the design and

Mine Metallurgy Custom Molding

On-demand Manufacturing of Mine Metallurgy Molding Much mechanical equipment in the mining and metallurgical industry, such as mine crushers, scraper conveyors, coal crushers, etc., will

Marine Custom Molding

On-demand Manufacturing of Marine Mouldings Marine mouldings applications require unique knowledge of the aggressive environment. The engineers at Zhongde have spent many years on the

Agricultural Machinery Custom Molding

On-demand Manufacturing of Agricultural Machinery Accessories Most agricultural machinery operates in the open, dusty, humid and dirty environment or in contact with water, soil, fertilizers,

Consumer Electronics Custom Molding

On-demand Manufacturing of Consumer Electronics Parts The consumer electronics parts industry is developing rapidly. The computers, laptops, calculators, telephones, remote controls, etc. that are common

Chemical Equipment Custom Molding

On-demand Manufacturing of Chemical Equipment Parts Molding Chemical equipment parts have high requirements for materials. Most of the materials in rubber and plastics are widely

Transmission Device Custom Molding

On-demand Manufacturing of Transmission System Molding Transmission system mainly refers to logistics transmission system, including production line transmission, logistics transmission, fully automatic transmission, etc. The

Communication Custom Molding

On-demand Manufacturing of Communication Components From developing specialized molded rubber solutions for Smart Grid technology to sealing GPS units and underground conduit ducts, Zhongde is

Home Appliances Custom Moulding

On-demand Manufacturing of Home Appliance Mould Zhongde manufactures home appliance mould parts for a variety of international appliance makers and suppliers, including assisting with the

Automotive Custom Moulding

On-demand Manufacturing of Automotive Molded Parts The automotive industry is evolving fast, constantly designing and developing new models, always in need of/needing customized auto molding

Custom Molding Parts Center