Why is Injection Molding so Expensive?

Why is injection molding so expensive? The high costs associated with plastic injection molding are driven by several factors, including mold design complexity, material choices, and

Home » Home Appliances Custom Moulding

Zhongde manufactures home appliance mould parts for a variety of international appliance makers and suppliers, including assisting with the design and material formulation. These home appliance moulds are used in small appliances, white goods, and large appliances and applications as diverse as vibration control, sealing holes in sheet metal, and cushioning support for large drums.

None of the parts pictured are in stock or for sale. These are all examples of custom-manufactured products that illustrate Zhongde’s capabilities. Welcome, to consult custom appliance rubber injection molding matters online!

Industry Expertise

Flexible Customization

Collaorative Approach

Why is Injection Molding so Expensive?

Why is injection molding so expensive? The high costs associated with plastic injection molding are driven by several factors, including mold design complexity, material choices, and

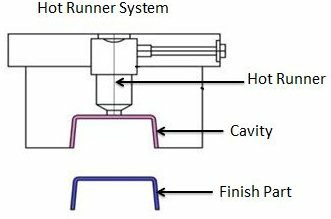

The Ultimate Guide to Hot Runner Systems and Enhanced Product Quality

Hot runner systems originated from non-runner systems in the injection molding industry. As an advanced plastic injection molding technology, its popularity can be traced back

Understanding Polymer Types: Comparing Plastics and Elastomers

When it comes to polymers, plastic and elastomer are two common polymer types. They are major players that dominate various industries. While they share the

Contact with us!

Get Your Parts in Higher Quality, Faster Delivery!

Email Us: sales@zdcpu.com