SLS 3D Printing Service

Order custom SLS parts suitable for rapid prototyping and end-use production.

Upload your CAD file to get instant quotes on SLS parts.

- All uploads are secure and confidential

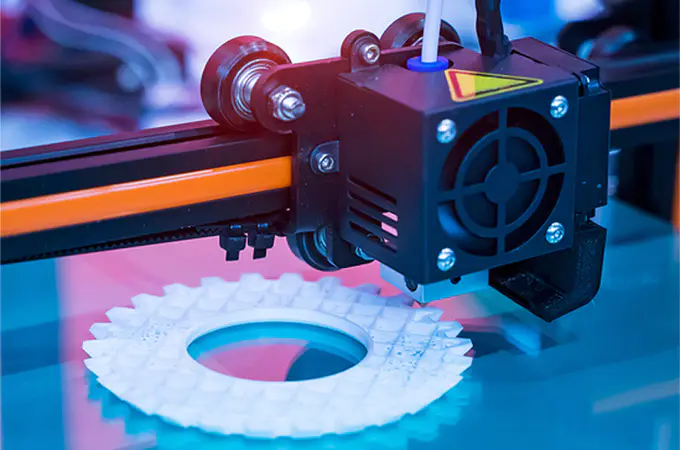

What Is SLS 3D Printing?

Selective Laser Sintering (SLS) is an industrial 3D printing process ideal for manufacturing end-use parts. In SLS 3D system, a laser selectively sinters polymer powder particles, fusing them together and building a part layer-by-layer. From SLS rapid prototyping to small-batch production, our SLS 3D printing facilities will allow you to produce highly accurate parts, with low cost and high quality comparable to injection molding.

SLS produces functional plastic parts with isotropic mechanical properties that can be used for detailed prototyping or end-use low-volume production.

Size of SLS 3D Printed Parts

The below table shows the size of the selective laser sintering SLS 3D printed parts we usually make. If you need a larger size, we can also help you achieve it.

| Standard Capabilities | Description |

|---|---|

| Requirement | Specification |

| Max Build Size | 300x300x300mm(11.8"x11.8"x11.8") |

| Standard Lead Time | 6 business days |

| Dimensional Accuracy | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012”) |

| Layer Height | 100μm |

*For expedited lead times or parts that exceed the maximum build size contact sales@zdcpu.com.

Available Material of SLS 3D Printing

Zhongde Selective Laser Sintering (SLS) 3D printing offers a wide range of materials suitable for various applications. Some common materials used in SLS 3D printing are as below. These materials enable the production of rapid prototypes, custom end-use parts, and complex geometries in various industries.

Metals

- Aluminum

- Cobalt Chrome

- Inconel

- Stainless Steel

Plastics

- ABS

- PA(Nylon)

- Polycarbonate

- Polypropylene

Elastomers

- TPU

- Silicone

* These materials are available by contacting sales@zdcpu.com.

SLS 3D Printing Design Guidelines

The following table summarizes the recommended and technically feasible values for the most common features encountered in 3D printed parts.

| Feature | Recommended Size |

|---|---|

| Unsuported Walls | 1mm(0.040") |

| Supported Walls | 0.7mm(0.030") |

| Minimum Detail Size | 0.25mm(0.010") |

| Minimum Hole Size | 1.0mm(0.040") |

| Moving Parts | 0.5mm(0.020")between moving surfaces |

| Assembly Clearance | 0.4mm(0.016")between mating surfaces |

| Max Wall Thickness | 20 mm (0.8''). Thicker parts must be hollowed with and at least two escape holes for powder removal with a min. diameter of 8 mm (0.3''). |

Custom Products

Service

Surface Finishing for 3D Printing

| Name | Description | Materail Compatibility | Color | Texture | |

|---|---|---|---|---|---|

|

Painting | Choose from a wide range of paints and coatings that can achieve the desired look and feel. | Plastics and metals | RAL or Pantone code | Gloss, semi-gloss, flat, metallic, textured |

|

Polishing | Achieve a smooth and glossy surface finish through mechanical polishing techniques. This process removes layer lines and imperfections, resulting in a refined appearance. | Plastics (PLA, ABS) | Raw material | Smooth and glossy |

|

Powder Coating | Apply a durable and protective powder coating to your 3D-printed part. This process involves electrostatic-ally applying a fine powder, which is then cured to create a tough and resistant finish | Metals (Alumium, stainless steel, steel) | Standard and custom options | Gloss or semi-gloss |

|

Bead Blasting | Utilize bead blasting to achieve a uniform and textured surface finish. This process involves propelling small abrasive particles at the surface of the object. | Metals and plastics | N/A | Matte or satin-like |

Related Services of Selective Laser Sintering

Overmolding & Insert Molding

Fused Deposition Modeling

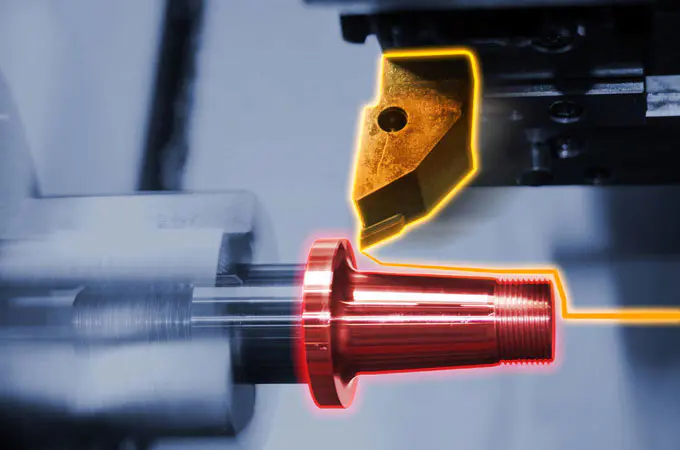

CNC Turning

Plastic Injection Molding

Rubber Injection Molding

CNC Milling

Knowledge Hubs

Factors Affecting the Price of Automotive Molds Processing

Due to the various advantages of injection molds, many manufacturers also like to use them, but different types of products

Solutions for Plastic Parts Color Unevenness

The plastic parts color uneven is one of the injection molding defects. It is a critical aspect of manufacturing that

What Are Common Medical Plastic Materials? How to Choose the Plastic?

With the global demand for high-quality medical devices, from test equipment like vials and beakers to surgical devices, catheters, and