Home » PU

PU

Material Type

Rubber

Material Full Name

Polyurethane

Process Compatibility

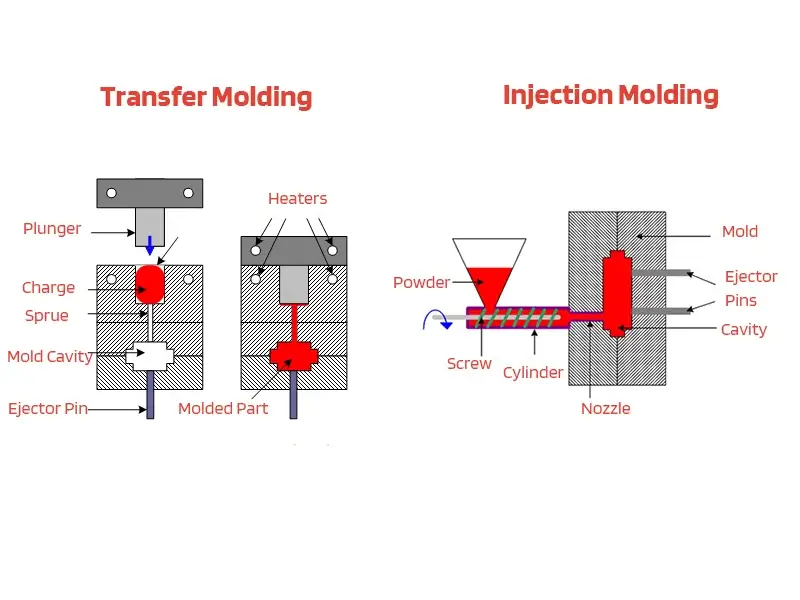

Compression Molding, Injection Molding, Cast Molding

List of Elastomer & Rubber Material

List of Plastic Material

List of Metal Material

PU Description

Price

$$$$$

Strength

Good resistance to abrasion, tearing, and weathering, wide range of mechanical properties, from soft and flexible to rigid and tough.

Weakness

Susceptibility to degradation when exposed to UV radiation,poor resistance to certain chemicals and solvents.

Common Application

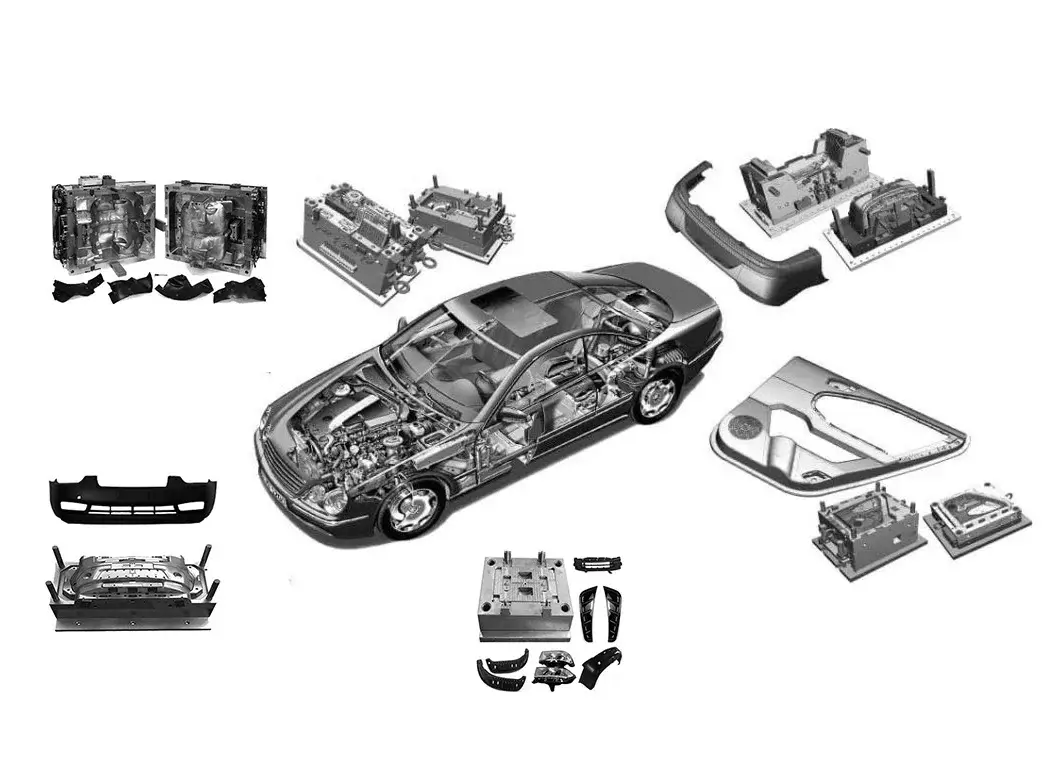

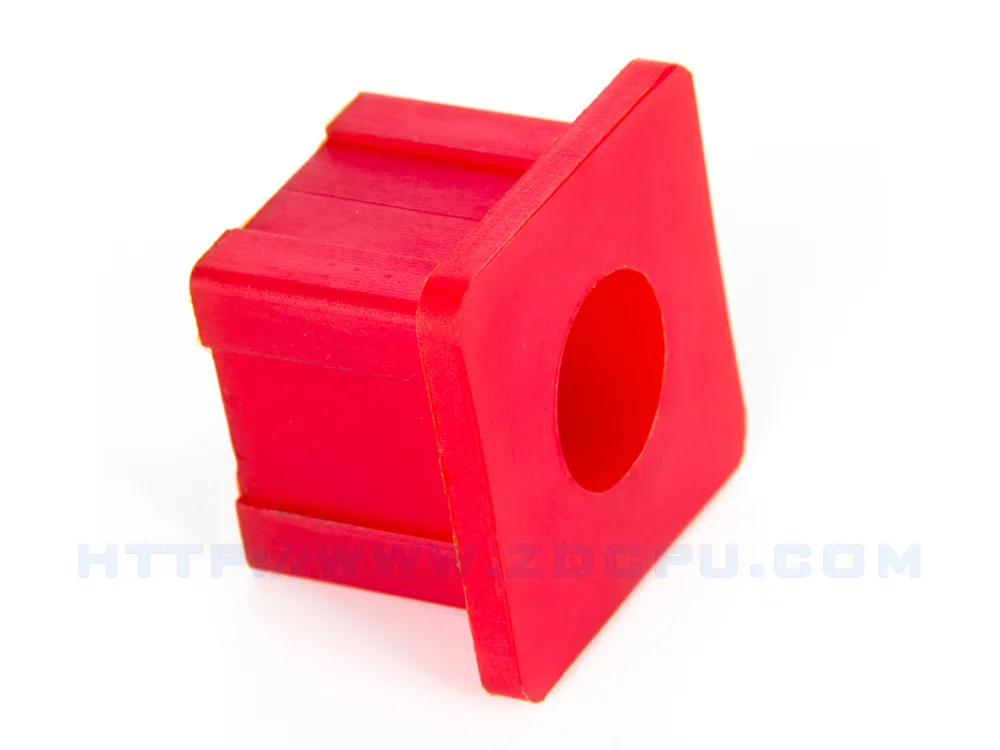

Automotive, construction, furniture, footwear, and coatings.

PU Properties

Polyurethane, also called urethane, commonly abbreviated as PU, is a versatile and widely used polymer in the plastic industry. It belongs to the family of polymers known as elastomers, and it is known for its flexibility, durability, and diverse range of applications.

Properties at a Glance

*Pease note: The following material properties are for reference only. Actual values may vary depending on the selected material brand.

| Property | Metric | English |

|---|---|---|

| Density | 0.9-1.2g/cm³ | 56.87-58.04 lb/ft³ |

| Shore Hardness A | 35-95 | 30-90 |

| Tensile Strength | 3.48-41.37 MPa | 500-6000 PSI |

| Elongation at Break | 250-900% | 250-900% |

| Min Temp. | -55~-40°C | -65~-40º F |

| Max Temp. | 80~105°C | 180~220º F |

Chemical Properties

- Limit resistance to acids and alkalies.

- Good resistance to fuel.

- Good oil resistance.

How to Improve PU Properties

Urethane material can be modified to enhance its properties. The following are some common types of additives and their functions,

- Plasticizers: Plasticizers are additives that improve the flexibility and softness of urethane materials. They work by reducing intermolecular forces between polymer chains, allowing for increased mobility and deformation. Common plasticizers include phthalates, adipates, and trimellitates.

- Fillers: Fillers are materials added to urethane formulations to improve mechanical properties such as strength, stiffness, and abrasion resistance. Examples of fillers include carbon black, silica, calcium carbonate, and glass fibers. They also help reduce material costs and shrinkage.

- UV Stabilizers: UV stabilizers protect urethane materials from degradation caused by exposure to ultraviolet (UV) radiation from sunlight. These additives absorb or scatter UV rays, preventing them from penetrating the polymer matrix and causing damage such as discoloration, embrittlement, and loss of mechanical properties.

Get Custom Urethane Parts with Zhongde

Is urethane good for the environment?

PU or urethane material doesn't harm the environment. Urethane doesn't consist of any chemicals that affect endocrine and hormone systems, and it does not contribute to the PH change in soil or water.

Can urethane material be bonded or adhered to other materials?

Urethane material can be bonded or adhered to other materials using various methods such as adhesives, bonding agents, or mechanical fasteners. Surface preparation, cleanliness, and compatibility between the materials are essential considerations for achieving strong and durable bonds.

Is urethane material suitable for outdoor applications?

Yes, urethane material is often suitable for outdoor applications. Urethane exhibits good resistance to weathering, UV radiation, and ozone exposure, making it suitable for use in outdoor environments.