Home » PC

PC

Material Type

Plastic

Material Full Name

Polycarbonate

Process Compatibility

Injection Molding

List of Plastic Material

List of Elastomer & Rubber Material

List of Metal Material

PC Description

Price

$$$$$

Strength

Withstand high impacts without breaking or shattering, high dimensional stability.

Weakness

Susceptibility to scratching and abrasion

Common Application

Safety goggles, bulletproof windows, water bottles, electronic components, and automotive parts.

PC Properties

Polycarbonate (PC) is a versatile and widely used engineering thermoplastic known for its excellent combination of properties, making it suitable for a diverse range of applications. It belongs to the family of thermoplastics known as polycarbonates, which are characterized by their clarity, impact resistance, and thermal stability. PC is valued for its optical clarity, impact resistance, and ease of processing, making it a popular choice in industries ranging from electronics to automotive.

Properties at a Glance

*Pease note: The following material properties are for reference only. Actual values may vary depending on the selected material brand.

| Property | Metric | English |

|---|---|---|

| Density | 1.15-1.2 g/cm³ | 71.80-74.73 lb/ft³ |

| Shore Hardness D | 90-95 | 90-95 |

| Transparency | 88-89% | 88-89% |

| Max Temp. Air | 100~140 °C | 212~284 °F |

| Flammabilitiy, UL94 | HB | HB |

| Elongation at Break | 50-120% | 50-120% |

Chemical Properties

- Excellent resistance to hydrolysis.

- Good resistance to acids and bases.

- Moderate resistance to organic solvents.

How Additives Improve PC Properties

PC can be modified to enhance its properties by adding additives, following are some common types:

- Flame retardant additives can improve the fire resistance of PC.

- UV stabilizers can be added to enhance PC's resistance to degradation caused by exposure to ultraviolet radiation.

- PC/ABS Blends: enhance impact resistance and improve processability, making it suitable for applications requiring toughness and rigidity, such as automotive interior parts and consumer electronics housings.

- PC/PMMA Blends: enhance optical clarity and weatherability, making it suitable for applications such as automotive lighting lenses and outdoor signage.

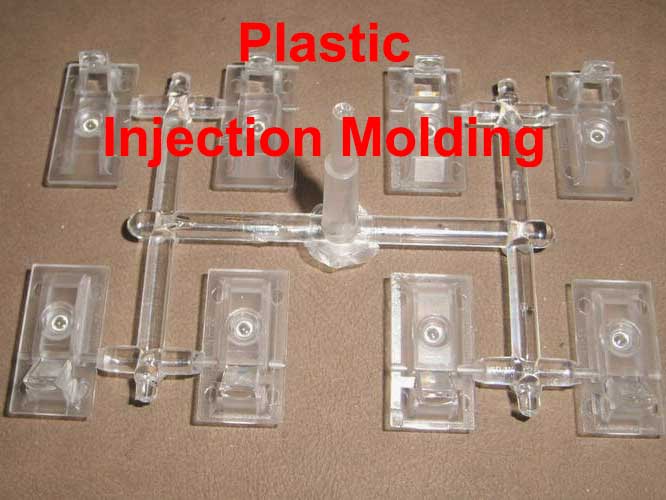

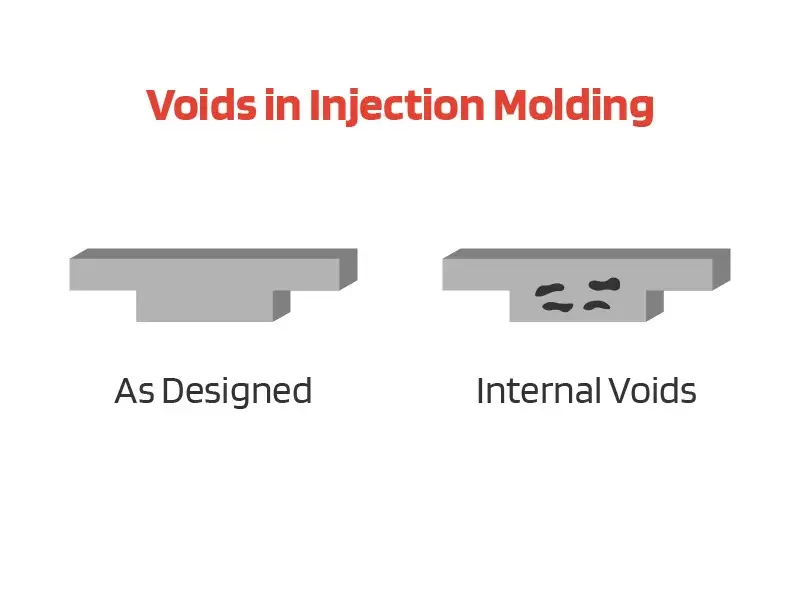

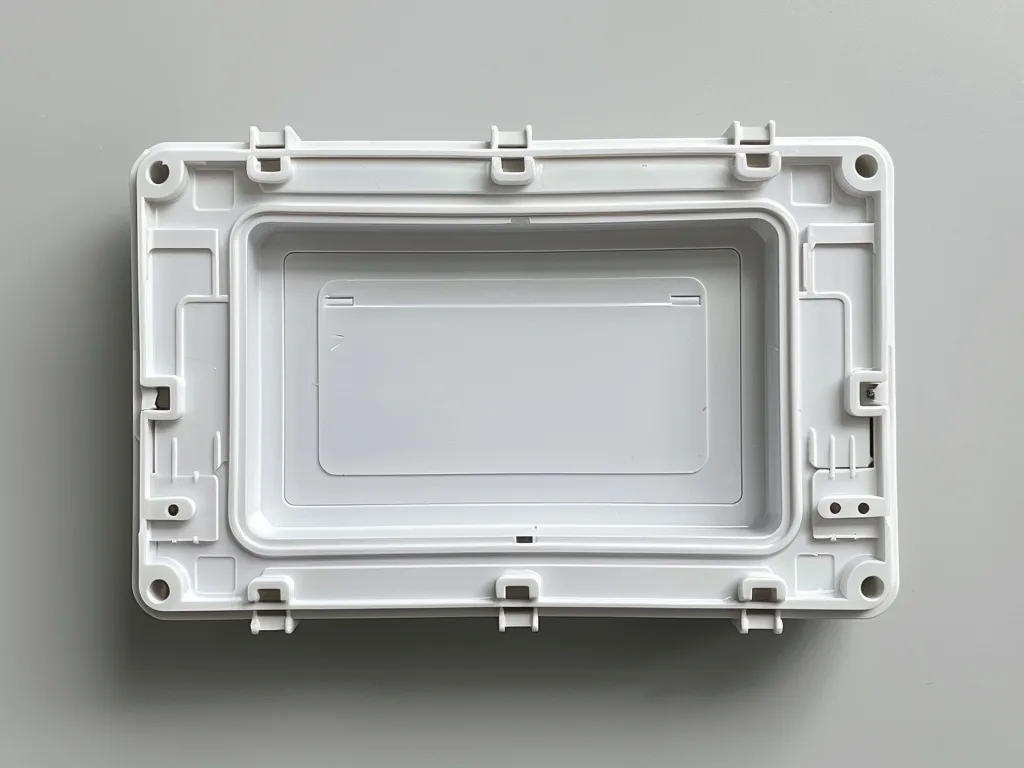

Injection Molding

A Comprehensive Guide For Polycarbonate Injection Molding

Polycarbonate injection molding is the process of injecting melted polycarbonate, a tough, transparent, and heat-resistant polymer, into a mold at high pressure and temperature to ...

2023-10-09

Get Custom PC Parts with Zhongde

Is PC safe for use?

Yes, PC material is generally considered safe for use in various applications. However, like any material, PC may release small amounts of bisphenol A (BPA) under certain conditions, which has raised some concerns about its safety. To address this, manufacturers often produce BPA-free PC products or use alternative materials for specific applications where BPA exposure is a concern.

Is PC material recyclable?

Yes, PC material is recyclable, but the recycling process can be more challenging compared to other plastics due to its high melting point and complex chemical composition.

What is general tolerance for PC injection molding parts?

The general tolerance for PC injection molding parts typically ranges from +/- 0.05 mm to +/- 0.1 mm, depending on factors such as part geometry, size, and specific requirements of the application.