Home » FKM

FKM

Material Type

Rubber

Material Full Name

Fluoroelastomer

Process Compatibility

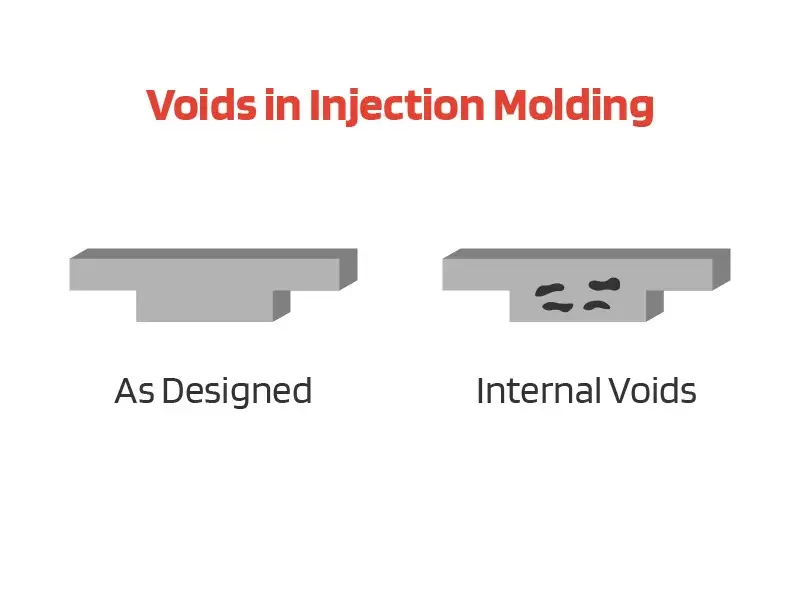

Compression Molding, Injection Molding

List of Elastomer & Rubber Material

List of Plastic Material

List of Metal Material

FKM Description

Price

$$$$$

Strength

Excellent resistance to heat, chemicals, fuels, oils, and solvents.

Weakness

High cost compared to other elastomers.

Common Application

Aerospace, chemical processing, oil and gas, and semiconductor manufacturing, where resistance to extreme temperatures, chemicals, and fluids is required.

FKM Properties

FKM is a family of fluorocarbon-based fluoroelastomer materials. It is commonly called fluorine rubber, fluoro-rubber or sometimes fluorel. Fluoroelastomers are more expensive than most rubber elastomers as they provide excellent properties, such as high temperature and aggressive fluid resistance.

Properties at a Glance

*Pease note: The following material properties are for reference only. Actual values may vary depending on the selected material brand.

| Property | Metric | English |

|---|---|---|

| Density | 1.85 g/cm³ | 115.47 lb/ft³ |

| Shore Hardness A | 50-95 | 50-95 |

| Tensile Strength | 3.48-13.79 MPa | 500-2000 PSI |

| Elongation at Break | 400-500% | 400-500% |

| Min Temp. | -35~-20°C | -30~0°F |

| Max Temp. | 230°C~260°C | 450~ 500º F |

Chemical Properties

- Excellent resistance to acids.

- Excellent resistance to fuel.

- Excellent resistance to most oils.

How to Improve FKM Properties

FKM can be modified through various methods which enable FKM to meet diverse application requirements, the most common methods include:

- Additives: Incorporating additives like plasticizers, fillers, antioxidants, and curing agents can enhance specific properties such as flexibility, abrasion resistance, thermal stability, and resistance to chemicals and weathering.

- Blending: Blending FKM with other elastomers or polymers can create hybrid materials with combined properties. For example, blending FKM with EPDM can improve flexibility, while blending it with ACM can enhance resistance to oils and fuels.

- Copolymerization: Copolymerizing FKM with other monomers can alter its chemical structure and properties. Introducing comonomers like vinylidene fluoride (VDF) or tetrafluoroethylene (TFE) can improve flexibility, lower glass transition temperature, or enhance processability.

Get Custom FKM Parts with Zhongde

Can FKM be recycled?

Yes, ABS is recyclable. It can be melted down and reshaped into new products, making it suitable for reuse. However, the recycling process can be challenging due to the diverse range of additives and the potential for degradation during multiple cycles of heating and cooling. Additionally, sorting ABS from other plastics in recycling streams can be difficult, which can hinder the efficiency of the recycling process.

Can FKM be used in food-contact applications?

FKM is ideal for use in food or pharmaceutical processing applications due to the unique combination of properties it provides. For example, FKM gaskets are commonly used in food, drink, and pharmaceutical applications.

Can FKM be bonded or adhered to other materials?

Yes, FKM can be bonded or adhered to certain materials using appropriate adhesives or bonding methods. Selecting compatible adhesives that are specifically formulated for bonding to FKM is crucial for successful adhesion.