A Comprehensive Guide to Low Pressure Injection Molding

Low pressure injection molding (LPM) is a specialized subset of traditional injection molding, distinguished by its use of lower pressure to inject the material into

Home » Agricultural Machinery Custom Molding

Most agricultural machinery operates in the open, dusty, humid and dirty environment or in contact with water, soil, fertilizers, pesticides, feces, decaying plants which are subject to corrosion by these materials and the environment. During operation, some agricultural machinery accessories rubbed against soil, crop rhizomes, livestock fur and other materials and were severely worn, and some agricultural machinery parts were subjected to relatively large dynamic loads and impacts.

In order to adapt to these special use environments, Zhongde adopts various processing techniques like butyl rubber injection molding to improve and enhance the performance of raw materials, improving the corrosion resistance and wear resistance of agricultural machinery components, reducing friction, improving impact resistance and other properties, and reduce costs. At present, the agricultural machinery parts that Zhongde has made mainly include sprinkler nozzles, rubber tracks, rubber rollers, hoses and various sealing bodies.

Industry Expertise

Flexible Customization

Collaorative Approach

A Comprehensive Guide to Low Pressure Injection Molding

Low pressure injection molding (LPM) is a specialized subset of traditional injection molding, distinguished by its use of lower pressure to inject the material into

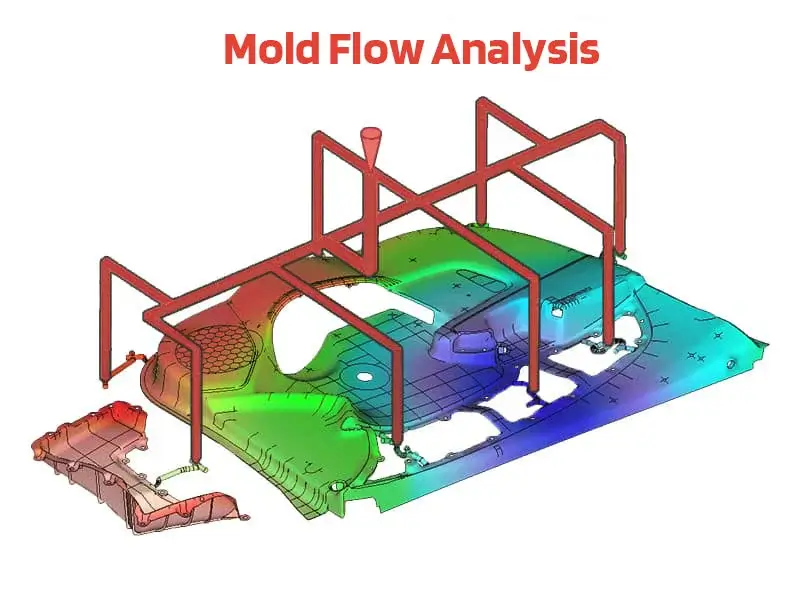

The Power of Mold Flow Analysis in Injection Mold Design

Mold flow analysis is an important tool in the manufacturing industry, especially in plastic injection molding. This analysis helps manufacturers optimize the design of injection

Flow Mark Injection Molding Causes and Prevent Solutions

Injection molding flow marks are a common injection molding defect. While flow marks generally do not influence the structural integrity of the part, they can

Contact with us!

Get Your Parts in Higher Quality, Faster Delivery!

Email Us: sales@zdcpu.com