3D Printing Service

High-quality custom 3D printed prototypes and on-demand production.

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- All uploads are secure and confidential!

Types of 3D Printing Service

FDM 3D Printing Service

SLS 3D Printing Service

3D Printing Materials

Plastic

- ABS

- PA(Nylon)

- Polycarbonate

- Polypropylene

Metals

- Aluminum

- Cobalt Chrome

- Inconel

- Stainless Steel

Surface Finishing for 3D Printing

| Name | Description | Materail Compatibility | Color | Texture | |

|---|---|---|---|---|---|

|

Painting | Choose from a wide range of paints and coatings that can achieve the desired look and feel. | Plastics and metals | RAL or Pantone code | Gloss, semi-gloss, flat, metallic, textured |

|

Polishing | Achieve a smooth and glossy surface finish through mechanical polishing techniques. This process removes layer lines and imperfections, resulting in a refined appearance. | Plastics (PLA, ABS) | Raw material | Smooth and glossy |

|

Powder Coating | Apply a durable and protective powder coating to your 3D-printed part. This process involves electrostatic-ally applying a fine powder, which is then cured to create a tough and resistant finish | Metals (Alumium, stainless steel, steel) | Standard and custom options | Gloss or semi-gloss |

|

Bead Blasting | Utilize bead blasting to achieve a uniform and textured surface finish. This process involves propelling small abrasive particles at the surface of the object. | Metals and plastics | N/A | Matte or satin-like |

3D Printing General Tolerance

| Description | Tolerance Notes |

|---|---|

| Linear Dimensions | +/- 0.1 mm to +/- 0.2 mm |

| Wall Thickness | +/- 0.1 mm to +/- 0.2 mm |

| Hole Diameter | +/- 0.2 mm to +/- 0.4 mm |

| Fillet Radius | +/- 0.2 mm to +/- 0.4 mm |

| Flatness | +/- 0.2 mm to +/- 0.4 mm |

| *The value are depending on the part size and technology. | |

Our Quality Promise

Zhongde is committed to providing quality products that meet or exceed the needs of our customers through continuous improvement.

Strictly follow the confirmed drawings or samples to produce. If there is any deviation, our company will replenish to our customers to make up for the loss.

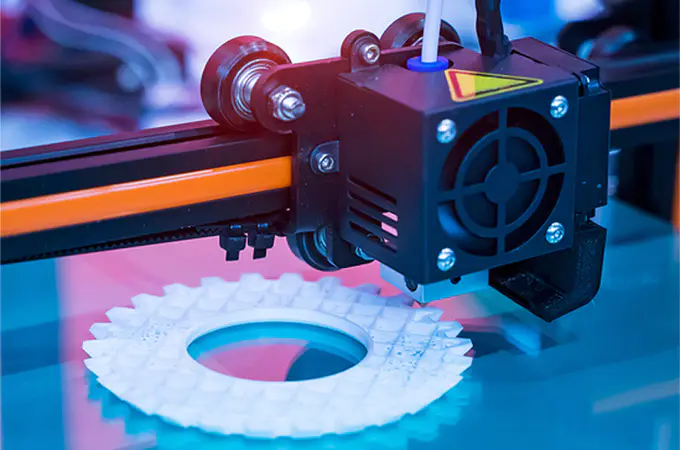

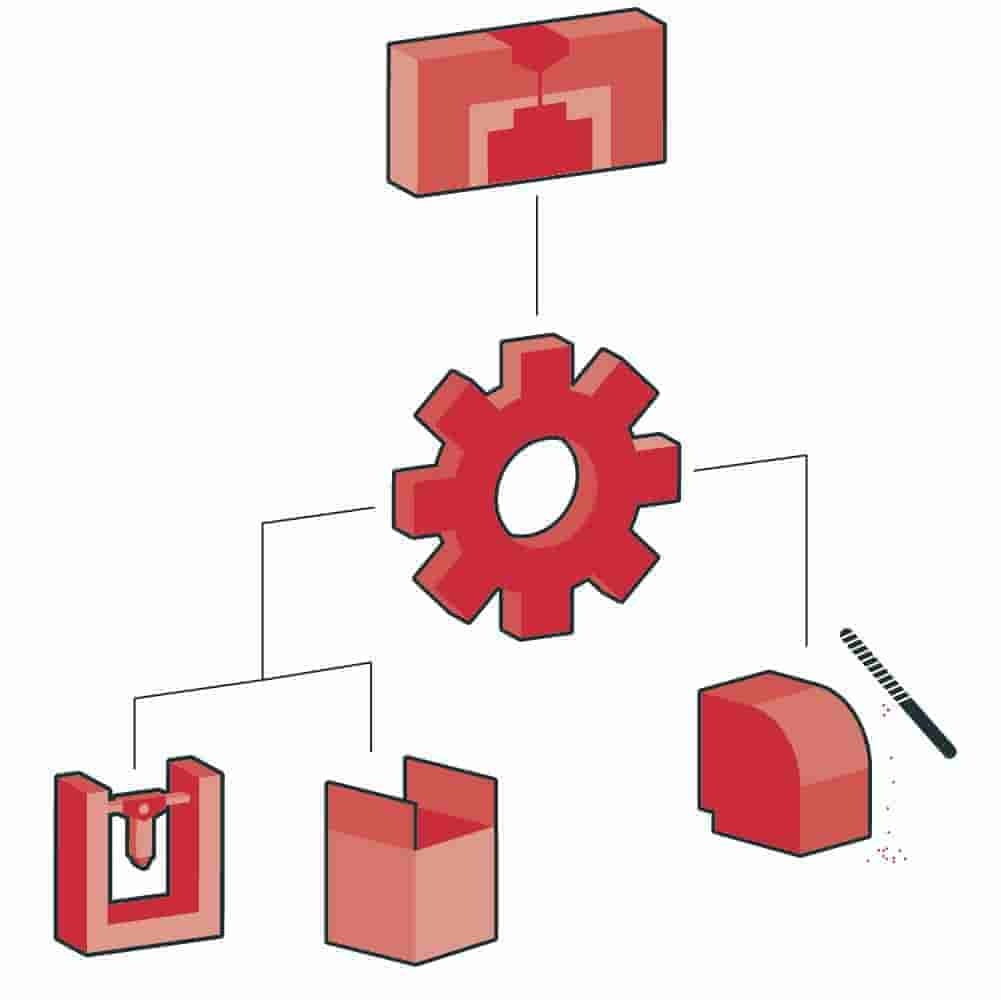

What is 3D Printing?

3D printing is also known as additive manufacturing. 3D printing creates three-dimensional objects by layering materials based on a digital model through the 3D printer. The 3D printer follows computer-aided design (CAD) file instructions to sequentially deposit or solidify materials, typically in thin layers, until the desired object is formed. This technology allows for the creation of complex and intricate shapes that may be difficult or impossible to achieve using traditional manufacturing methods.

Zhongde offers 3D printing rapid prototyping services and solutions to meet your special needs, such as 3D printed molds for injection molding. 3D printed molds are low prototype cost and short time.

Advantages of 3D Printing

Geometric complexity at no extra cost

Very low start-up costs

Customization of each and every part

Save material and energy suitable for mass production

Easy to operate with low production cost

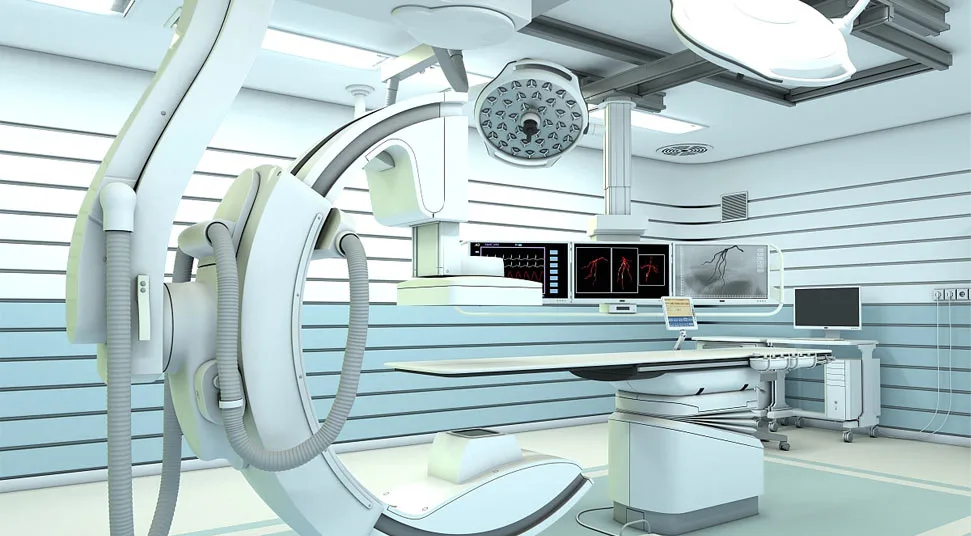

Applications of 3D Printing

Why Choose Zhongde for 3D Printing

Cost Effective

Consistency and High Quality

Proven Success

Complete Range of Service

Start A New Project Right Now!

FAQs of 3D Printing

Can 3D printing be used for large-scale production?

What file format is required for 3D printing?

What is the typical turnaround time for 3D printing projects?

Can 3D-printed objects be post-processed or finished?

Knowledge Hubs

6 Kinds of Plastic Die Molds, Do You Know Them All?

Plastic die moulds are tools that are matched with plastic molding machines in the plastic processing industry to give plastic products a complete configuration and

The Development of Hot Compression Molding and Its Technology Equipment

Various new materials and process technologies for hot compression molding (such as: WCM, LFI, PHC, DFCM, RPM, TPF, etc.) continue to emerge, expanding and enriching

A Comprehensive Guide For ABS Injection Molding

ABS Injection Molding ABS injection molding is a versatile and widely used manufacturing process, utilizing Acrylonitrile Butadiene Styrene (ABS) as the primary material. The ABS