Home » Material Selection » POM

POM

Material Type

Plastic

Material Full Name

Polyoxymethylene

Process Compatibility

Injection Molding, Extrusion, CNC Machining,

3D Printing

List of Plastic Material

List of Elastomer & Rubber

List of Metal Material

Custom POM Part manufacturing Solution

Start A New Project Right Now!

POM Description

Price

Strength

High stiffness, excellent mechanical properties, good dimensional stability, and low friction coefficient

Weakness

Poor resistance to acids and bases, limited resistance to high temperatures, and challenges in achieving high-quality surface finishes

Common Application

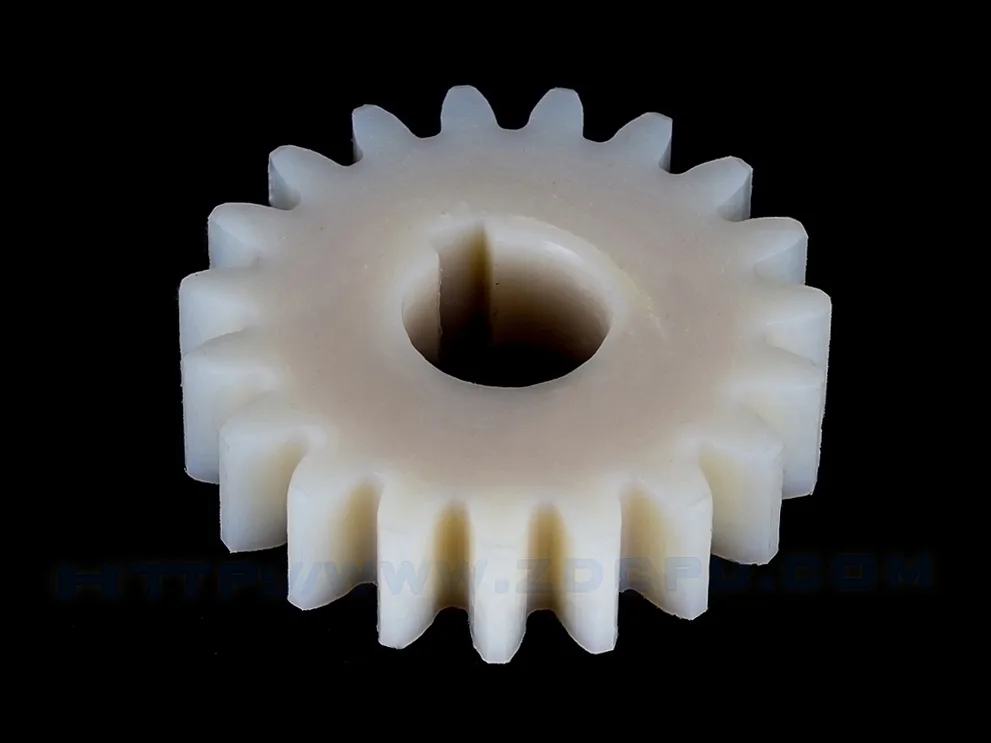

Gears, pumps and pump impellers, fan and blower blades, automotive switches, electrical switch components, buttons, and knobs

POM Properties

In terms of processing, POM is mainly produced by injection molding, which is suitable for mass production of complex parts with high dimensional accuracy. Extrusion molding is commonly used to manufacture rods, tubes, and profiles to meet continuous production needs. Machining is often applied for secondary processing of POM rods and sheets, making it suitable for small to medium batches or parts requiring higher precision. While 3D printing can be used for prototypes or small-batch trials of POM, the process is relatively challenging and less commonly applied.

| Property | Metric | English |

|---|---|---|

| Density | 1.41-1.43g/cm³ | 0.051-0.052 lb/in³ |

| Shore Hardness D | 80-95 | 80-95 |

| Min Temp. Air | -40°C | -40°F |

| Max Temp. Air | 80~105°C | 176-221°F |

| Flammabilitiy, UL94 | HB | HB |

| Elongation at Break | 15~75% | 15~75% |

*Please Note: Material properties are for reference only and may vary by brand.

How Additives Improve POM Properties?

In POM parts manufacturing, Various additives can be incorporated into POM to enhance its properties:

- Lubricants: Improve wear resistance and reduce friction.

- Reinforcements (such as glass fibers or carbon fibers): Enhance strength and stiffness.

- Impact modifiers: Increase toughness and impact resistance.

- UV stabilizers: Protect against degradation from UV radiation.

Get POM Part Molding with Zhongde

FAQs of POM Materials

Can POM be recycled?

What are the types of POM material?

Is POM stronger than nylon?

It is easy to fill the form.

Better Quality, Faster Delivery

Upload your design drawing and all uploads are secure and confidential!