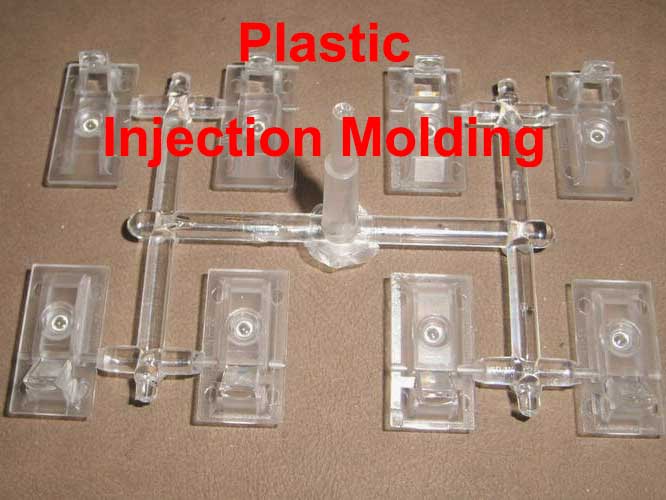

Polycarbonate injection molding is the process of injecting melted polycarbonate, a tough, transparent, and heat-resistant polymer, into a mold at high pressure and temperature to create complex plastic parts with excellent optical clarity, impact resistance, and mechanical properties. In this post, we will explore the significance and practical applications of PC injection molding, you will learn its process, advantages, common issues, and design principles.

What is Polycarbonate Material?

Polycarbonate, often referred to as PC, is a thermoplastic polymer known for its exceptional characteristics. It has gained widespread recognition in various industries due to its impressive combination of physical and chemical properties.

Plastic Material - Polycarbonate

Polycarbonate Grades for Injection Molding

Polycarbonate comes in several types or grades. Common grade polycarbonates include Medical-Grade Polycarbonate, Food-Grade Polycarbonate, and Generic-Grade polycarbonate.

However, fillers or additives can be added to Polycarbonate to meet specific applications.

Optical grade polycarbonate molded parts are optically clear and have near-total light transmittance and a very low haze factor. UV additives often adapt to PC to protect against direct, long-term exposure to sunlight. By adding flame retardant, polycarbonate can meet the UL 94 standard.

Properties of Polycarbonate

| Property | Value |

|---|---|

| Density (g/cm³) | 1.2 – 1.22 |

| Shrinkage Rate (%) | 0.4 – 0.7 |

| Tensile Strength at Yield (MPa) | 55 – 75 |

| Elongation at Break (%) | 80-150 |

| Flexural Modulus (GPa) | 2.2-2.4 |

| Flexural Strength (MPa) | 75-100 |

| Drying Temperature (°C) | 80-100 |

| Drying Time (hrs) | 2-4 |

| Melt Temperature (°C) | 220-260 |

| Mold Temperature (°C) | 70-100 |

Polycarbonate Injection Molding Design Guidelines

When designing PC injection molding parts, these guidelines help ensure that PC parts meet end-use requirements and maintain high quality.

Wall Thickness

Aim for a minimum wall thickness of 0.040 inches (1 mm) and a maximum of 0.150 inches (3.8 mm) for PC parts. This range supports thin walls and complex geometries.

How to maintain uniform thickness, read our previous blog to get a comprehensive understanding of wall thickness design guidelines.

Rib Thickness

When using ribs for additional strength or support, make the rib thickness between 0.5 and 0.6 times the thickness of the adjoining wall. Avoid using rib heights more than three times the thickness.

Corner Radii

Prevent stress concentrations by avoiding sharp corners. Use a corner radius of at least 0.125 inches (3 mm) in PC injection molded parts.

Draft Angle

Incorporate a draft angle, typically ranging from 0.5° to 1° per side, to assist with part ejection from the mold. Adjust the draft angle as needed based on part shape and mold design.

Gate Location

When designing the gate location for polycarbonate injection molding parts, it’s crucial to prioritize the prevention of weld lines, as they can significantly weaken the part’s structural integrity and harm its aesthetic appearance.

Injection Molding Gate Design: Enhancing Plastic Manufacturing presents more details about injection molding gate.

Surface Finish

Polycarbonate supports a variety of surface finishes, including gloss and high-gloss finishes. Matte finishes can reduce glare, making them suitable for control panel overlays. Non-glossy finishes may be preferred for certain applications like screw caps.

Polycarbonate Injection Molding Processing Guide

Polycarbonate injection molding is a manufacturing process used to create various plastic parts and components from Polycarbonate resin. The process typically includes steps such as material preparation, mold design, machine setup, injection of the molten Polycarbonate, cooling, ejection, quality control, and the repetition of these steps for mass production. Proper control of temperature settings, injection parameters, cooling, and cycle times is essential to achieve consistent and reliable results in PC injection molding.

Considerations During Polycarbonate Injection Molding Process

Compared with other plastic injection molding, the polycarbonate injection molding process requires special attention. Our previous blog Principle of Injection Molding Process explains the injection molding process in detail.

- Material Drying: Polycarbonate is sensitive to moisture, so proper material drying is critical before processing. Ensure that the polycarbonate pellets are adequately dried to prevent moisture-related defects like bubbles or splay marks.

- Precise Mold Temperature Control: Polycarbonate’s high shrinkage rate and sensitivity to cooling can result in warping or dimensional inaccuracies. Therefore, precise mold temperature control is essential to achieve uniform cooling and minimize part stress.

- Longer Cooling Time: Polycarbonate parts require adequate cooling time to solidify and maintain their shape. Longer cooling times may be needed compared to some other plastics.

Parameters for PC Injection Molding Process

Here are the typical ranges for some key PC injection molding process parameters for reference. The specifications parameter number needs to be adjusted depending on PC types and grades.

- Polycarbonate Injection Molding Temperature: Generally, the recommended melt temperature for polycarbonate material falls within the range of 260°C to 320°C (500°F to 608°F).

- Polycarbonate Injection Mold Temperature: Mold temperature can vary depending on the specific application, but it is generally set in the range of 70°C to 95°C (158°F to 203°F) for Polycarbonate.

- Polycarbonate Injection Pressure: Injection pressure is typically set between 70 MPa and 140 MPa (10,000 psi to 20,000 psi) to ensure proper material flow and filling.

- Back Pressure: Back pressure can vary but is often set between 2 MPa and 10 MPa (300 psi to 1500 psi) to assist in plasticizing the PC material.

- Holding Pressure: Holding pressure, applied after injection, is typically set between 50% and 80% of the injection pressure to prevent part shrinkage.

- Injection Speed: Injection speed can vary based on part design and size but is often set in the range of 50 mm/s to 200 mm/s (2 in/s to 8 in/s).

- Screw Speed: Screw speed varies depending on the machine and material, but it typically ranges from 50 RPM to 200 RPM.

Advantages of Polycarbonate Injection Molding

Exceptional Impact Resistance

PC is known for its exceptional impact resistance. Compared with other plastic materials, It can withstand significant forces without breaking, making it suitable for applications where durability is crucial.

Transparency

PC is highly transparent, with optical clarity close to that of glass. This transparency is advantageous for products like lenses, windows, and displays. Many other plastics are not as transparent or may require additional processes to achieve clarity.

High Heat Resistance

PC retains its properties at elevated temperatures, making it suitable for components exposed to heat and thermal stress. This advantage is particularly valuable in applications like automotive lighting and electronics, where heat resistance is required.

Chemical Resistance

PC exhibits resistance to various chemicals, which makes it suitable for applications in chemically challenging environments. Not all plastics offer the same level of chemical resistance.

Electrical Insulation

PC serves as an excellent electrical insulator, making it suitable for electrical and electronic components. Some other plastics may not provide the same level of electrical insulation.

Polycarbonate Injection Molding Troubleshooting

Shrinkage

Polycarbonate can experience significant shrinkage as it cools after injection. This can lead to dimensional inaccuracies in the final part. To mitigate shrinkage, adjust mold design for compensation, lower melt temperature to reduce cooling rate, and apply proper packing and holding pressure during molding.

Warping

Warping, or deformation of the part after molding, can occur due to uneven cooling rates or internal stresses. Prevent warping by ensuring uniform cooling, using mold design features like cooling channels, and implementing post-molding annealing processes.

Surface Defects

Polycarbonate parts may develop surface defects like blemishes, streaks, or surface haze during molding. Achieve a flawless surface finish by maintaining clean mold surfaces, optimizing processing conditions, and using mold release agents and venting as needed.

Hydrolysis and Degradation

Polycarbonate can be sensitive to moisture and high temperatures, potentially leading to hydrolysis and material degradation. Prevent hydrolysis and degradation by thoroughly drying the material, maintaining temperature control, and considering additives or stabilizers to enhance resistance.

Applications of Polycarbonate Injection Molding

Polycarbonate injection molding finds applications in various industries. Especially due to its excellent optical clarity, it is used for eyewear lenses, optical discs, and components in the optical industry. Here are some of the applications.

Automotive Industry

Polycarbonate is used for automotive components such as headlamp lenses, interior trim, and window glazing due to its impact resistance and lightweight properties.

Electronics

It is used in electronic enclosures, connectors, and components due to its electrical insulating properties and heat resistance.

Medical Devices

Polycarbonate is employed in medical equipment and devices, including IV connectors, housings, and surgical instruments.

Optical Industry

It is used for eyewear lenses, optical discs, and components in the optical industry due to its excellent optical clarity.

Aerospace

Polycarbonate finds applications in aircraft interiors, including windows, panels, and interior components, where lightweight and high strength are essential.

Lighting

Polycarbonate is used in lighting fixtures, including diffusers and lenses, due to its optical properties and resistance to UV radiation.

Conclusion

In summary, Polycarbonate injection molding is a versatile and widely used manufacturing process known for its ability to produce high-quality parts with exceptional properties. If you have a project that could benefit from Polycarbonate injection molding, don’t hesitate to explore its potential. Whether you’re in the automotive, medical, or any other industry, Polycarbonate could be the solution you need. For reliable Polycarbonate injection molding services, consider reaching out to Zhongde, your trusted partner in manufacturing excellence.