Home » Material Selection » PC

PC

Material Type

Plastic

Material Full Name

Polycarbonate

Process Compatibility

Injection Molding, Extrusion, CNC Machining,

PC Bonding Plastic, Bonding PC to Metal, 3D Printing

List of Plastic Material

List of Elastomer & Rubber

List of Metal Material

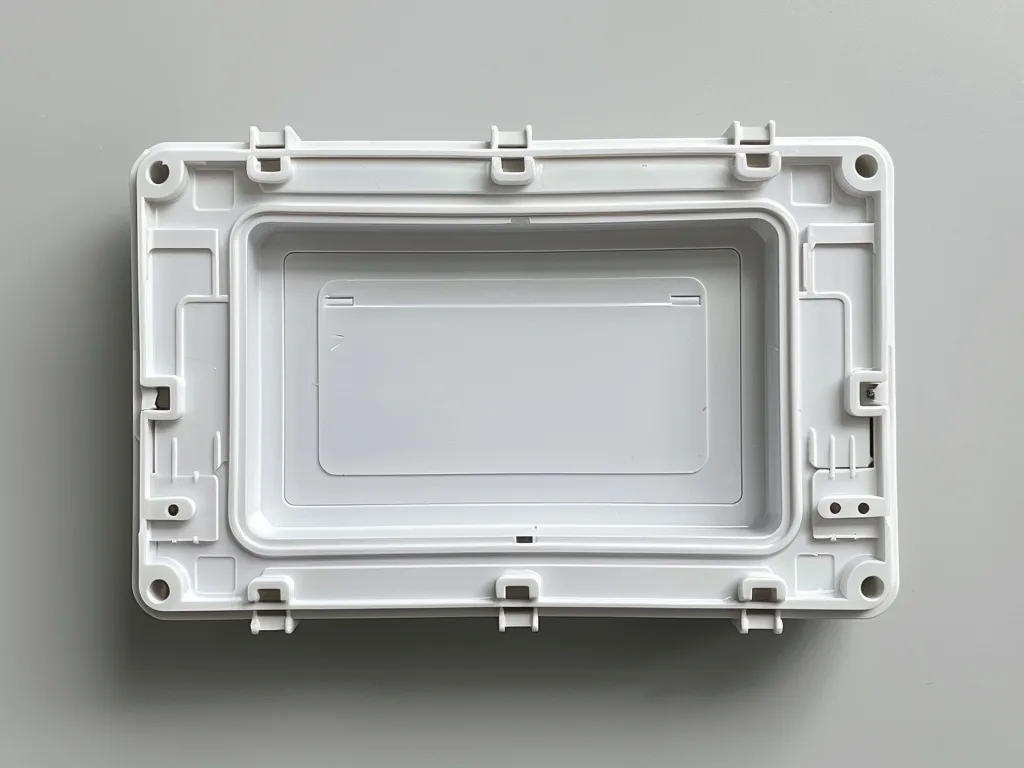

Custom Polycarbonate Molding Solution

Start A New Project Right Now!

PC Description

Price

Strength

Withstand high impacts without breaking or shattering, high dimensional stability

Weakness

Common Application

Safety goggles, bulletproof windows, water bottles, electronic components, and automotive parts

PC Properties

PC is commonly processed through injection molding, extrusion, and machining. Injection molding is preferred for high-volume production of complex parts requiring precise dimensions. Extrusion is used for continuous profiles such as sheets and tubes, offering consistent thickness and surface quality. Machining is suitable for small batches or prototypes where detailed features and tight tolerances are necessary.

| Property | Metric | English |

|---|---|---|

| Density | 1.15-1.2 g/cm³ | 71.80-74.73 lb/ft³ |

| Shore Hardness D | 90-95 | 90-95 |

| Transparency | 88-89% | 88-89% |

| Max Temp. Air | 100~140 °C | 212~284 °F |

| Flammabilitiy, UL94 | HB | HB |

| Elongation at Break | 50-120% | 50-120% |

*Please Note: Material properties are for reference only and may vary by brand.

How Additives Improve PC Properties?

PC can be modified to enhance its properties by adding additives, following are some common types:

- Flame retardant additives can improve the fire resistance of PC.

- UV stabilizers can be added to enhance PC’s resistance to degradation caused by exposure to ultraviolet radiation.

Blending PC with other polymers can mix their strengths and minimize their weaknesses, for instance:

- PC/ABS Blends: enhance impact resistance and improve processability, making it suitable for applications requiring toughness and rigidity, such as automotive interior parts and consumer electronics housings.

- PC/PMMA Blends: enhance optical clarity and weatherability, making it suitable for applications such as automotive lighting lenses and outdoor signage.

Get PC Injection Parts with Zhongde

FAQs of PC Materials

Is PC safe for use?

Is PC material recyclable?

What is general tolerance for PC injection molding parts?

It is easy to fill the form.

Better Quality, Faster Delivery

Upload your design drawing and all uploads are secure and confidential!