Home » Material Selection » PP

PP

Material Type

Plastic

Material Full Name

Polypropylene

List of Plastic Material

List of Elastomer & Rubber

List of Metal Material

Custom Plastic PP Manufacturing Solution

Start A New Project Right Now!

PP Description

Price

Strength

High chemical resistance, lightweight properties, low moisture absorption, excellent fatigue resistance, good electrical insulation

Weakness

Susceptibility to UV degradation, poor resistance to high temperatures, tendency to warp under stress, and limited impact strength

Common Application

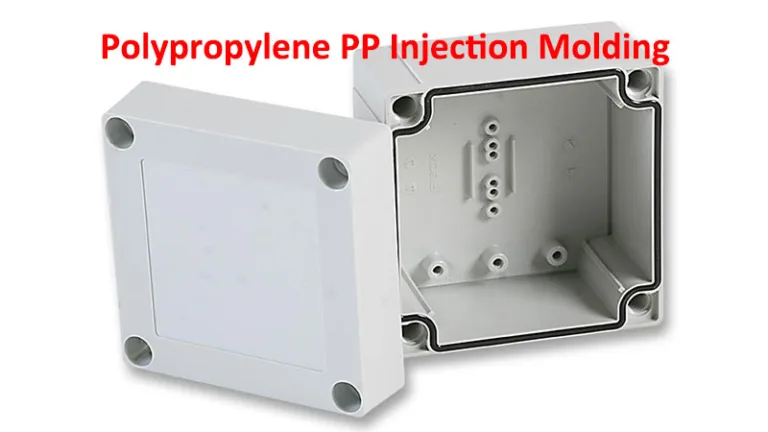

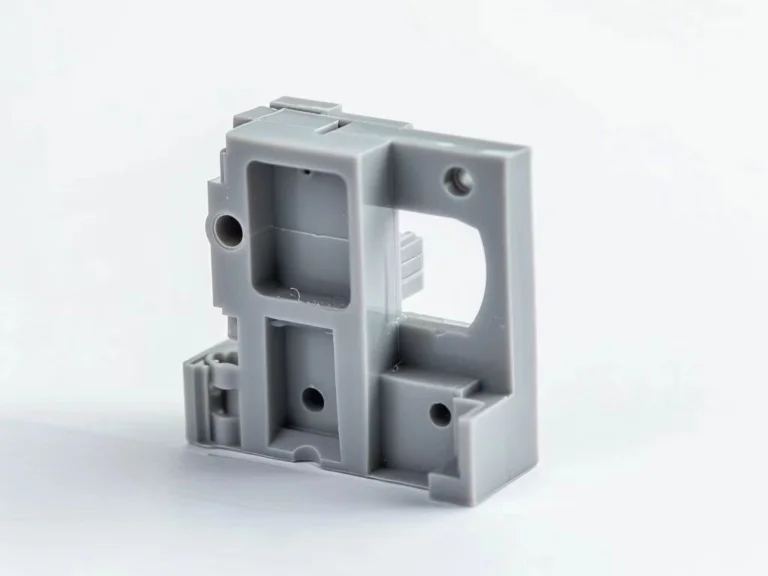

PP is commonly used in packaging, automotive components, consumer products, textiles, and medical devices

PP Properties

PP is commonly processed through injection molding and extrusion. Injection molding is used when tight tolerances and complex shapes are needed, while extrusion is better for producing continuous lengths like tubes or profiles. Machining is used in very simple scenarios where high precision is not required

| Property | Metric | English |

|---|---|---|

| Density | 0.9 g/cm³ | 0.033 lb/in³ |

| Shore Hardness D | 45-55 | 45-55 |

| Min Temp. Air | -40-20°C | -40 - 68 °F |

| Max Temp. Air | 80-130 °C | 176 - 266 °F |

| UL94 Fire Rating | HB | HB |

| Elongation at Break | 8-12% | 8-12% |

*Please Note: Material properties are for reference only and may vary by brand.

How Additives Improve PP Properties?

Polypropylene (PP) can be customized by adding various additives during compounding to improve its performance for different applications, making it highly suitable for polypropylene injection moulding and PP extrusion.

- UV Stabilizers: Improve resistance to ultraviolet light, extending outdoor lifespan.

- Antioxidants: Protect against thermal degradation during processing and use.

- Nucleating Agents: Enhance stiffness and clarity by promoting crystallization.

- Fillers (e.g., talc, glass fibers): Increase stiffness and strength but may reduce impact resistance.

- Impact Modifiers: Boost toughness and reduce brittleness.

- Flame Retardants: Enhance fire resistance, sometimes at the cost of mechanical or processing properties.

Get PP Plastic Manufacturing with Zhongde

FAQs of PP Materials

Is PP recyclable?

Is PP safe?

What are the types of PP?

- Homopolymer PP: Consists of only propylene monomer units and offers good stiffness, strength, and chemical resistance.

- Copolymer PP: Contains a blend of propylene and ethylene monomer units, providing improved impact resistance and clarity compared to homopolymer PP.

- Random Copolymer PP: Incorporates ethylene randomly along the polymer chain, enhancing flexibility and impact resistance while maintaining high chemical resistance.

It is easy to fill the form.

Better Quality, Faster Delivery

Upload your design drawing and all uploads are secure and confidential!