Home » Elastomer & Rubber » PU

PU

Material Type

Rubber

Material Full Name

Polyurethane/Urethane

Process Compatibility

PU Casting

List of Elastomer & Rubber Material

List of Plastic Material

List of Metal Material

Custom PU Casting Solution

Zhongde provide custom PU casting solutions covering everything from mold making to final production. Our process ensures precise shapes, consistent quality, and PU parts tailored to your needs.

Start A New Project Right Now!

If PU is the right material for your application, simply send us your drawings or samples.

PU Description

Price

$$$$$

Strength

Good resistance to abrasion, tearing, and weathering, wide range of mechanical properties, from soft and flexible to rigid and tough.

Weakness

Susceptibility to degradation when exposed to UV radiation,poor resistance to certain chemicals and solvents.

Common Application

Automotive, construction, furniture, footwear, and coatings.

PU Properties

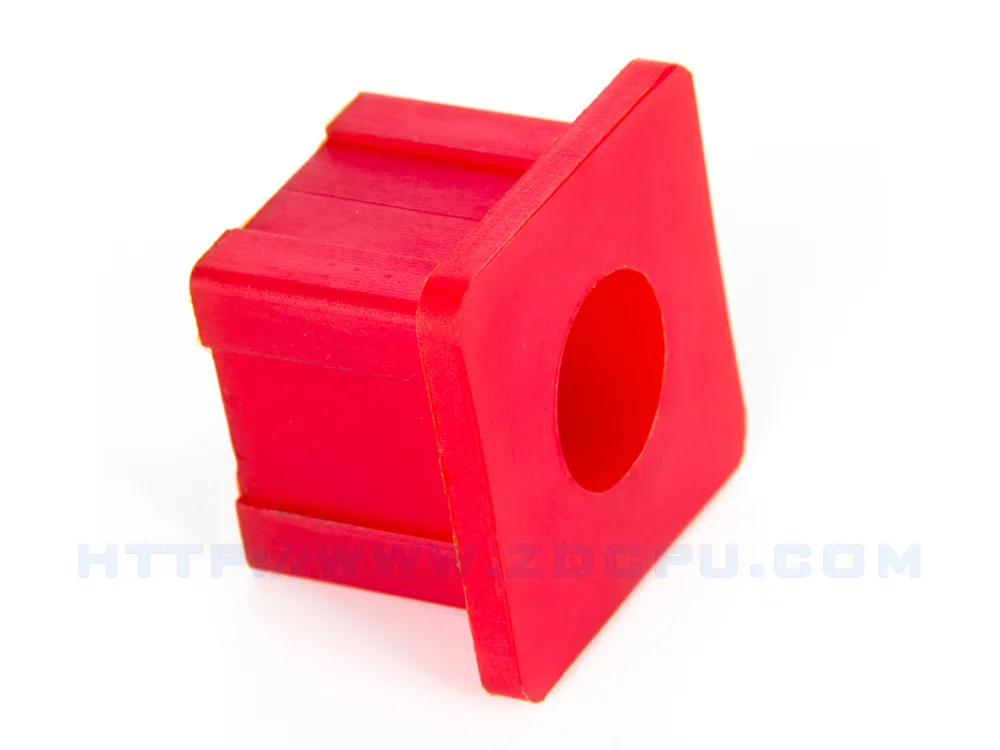

Polyurethane (PU) consists of flexible polyol and rigid isocyanate segments, providing good abrasion resistance, elasticity, and impact absorption. Its structure supports a wide range of hardness from soft foam to rigid parts. PU casting enables the production of complex shapes with accurate dimensions and smooth surfaces, suitable for durable custom parts and prototypes.

| Property | Metric | English |

|---|---|---|

| Density | 1.1 – 1.25 g/cm³ | 0.0397 – 0.0450 lb/in³ |

| Shore Hardness D | 20 – 90 | 20 – 90 |

| Min/Max Temperature | -40 °C to 120 °C | -40 °F to 248 °F |

| UL94 Flammability | HB to V-0 | HB to V-0 |

| Elongation at Break | 100% – 600% | 100% – 600% |

*Please Note: Material properties are for reference only and may vary by brand.

How Additives Improve PU Properties?

To meet diverse application demands, various additives are incorporated into PU formulations to improve its properties.

- Plasticizers: Increase flexibility and softness for softer foam or elastomeric parts.

- UV Stabilizers: Protect against degradation and discoloration from sunlight exposure.

- Antioxidants: Prevent oxidation and extend material lifespan.

- Flame Retardants: Enhance fire resistance to meet safety standards.

- Fillers: Improve mechanical strength, reduce cost, or modify hardness.

- Crosslinking Agents: Improve chemical resistance and mechanical durability.

Get PU Casting Parts with Zhongde

Zhongde specializes in PU casting, offering precise, durable, and customizable polyurethane parts with efficient production and strict quality control for diverse applications.

FAQs of PU Materials

View our FAQ center for more questions.

What is the typical lifespan of PU products under normal conditions?

PU products usually last several years but lifespan depends on exposure to UV, chemicals, and mechanical stress.

Is PU material recyclable or eco-friendly?

PU recycling is possible but less common; environmental impact depends on formulation and disposal methods.

Can PU materials be bonded or coated easily?

Yes, PU can be bonded with adhesives and coated for additional properties like abrasion or chemical resistance.

It is easy to fill the form.

Better Quality, Faster Delivery

From design to final parts, from rapid prototyping to mass production, Zhongde's one-stop service meets your needs.

Upload your design drawing and all uploads are secure and confidential!

Upload your design drawing and all uploads are secure and confidential!