Home » Material Selection » Copper

Copper

Material Type

Metal

Process Compatibility

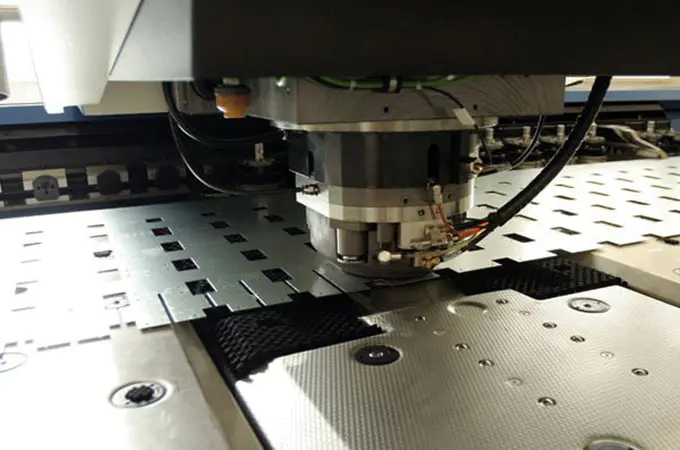

CNC Machining, Metal Stamping

List of Metal Material

List of Plastic Material

List of Elastomer & Rubber

High Precision Copper Fabrication Solution

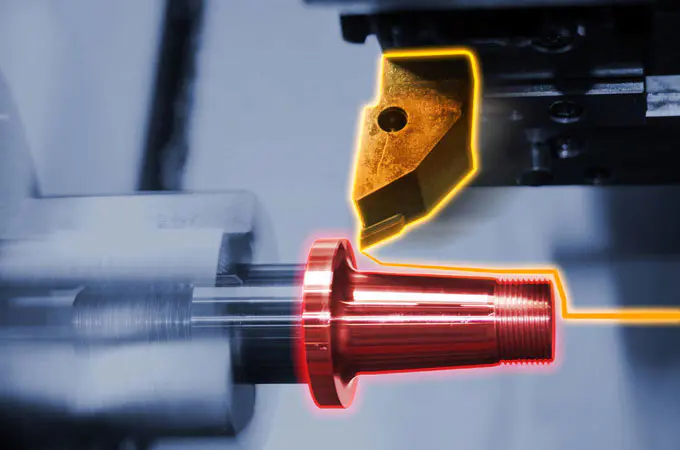

Zhongde utilizes multi-axis CNC machines and optimized processes to achieve micron-level tolerance control for complex copper parts. By adjusting cutting parameters to suit copper’s high conductivity and softness, we minimize burrs and deformation while ensuring excellent surface finish. Suitable for prototypes to high-volume production, with applications in heat sinks, connectors, and precision metal CNC machining parts.

Start A New Project Right Now!

If copper is the right material for your application, simply send us your drawings or samples.

Copper Description

Price

$$$$$

Strength

Excellent electrical and thermal conductivity, corrosion resistance, malleability, and antimicrobial properties

Weakness

Susceptibility to oxidation, tendency to tarnish over time, and softer than some other metals

Common Application

Electrical wiring and cables, plumbing pipes and fittings, roofing materials, heat exchangers and radiators

Available Copper Materials

Copper 101

Copper 101, also called oxygen-free copper (OFC), has extremely high purity and conductivity, with oxygen content under 0.001%. It’s ideal for CNC copper machining due to its excellent electrical and thermal performance.

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 69-365 MPa | 5-55% | 65-90HB | 8.89-8.94 g/cm³ |

Copper 110

Copper C110, also known as electrolytic tough pitch (ETP) copper, is distinguished by its high conductivity and excellent thermal properties. It is commonly used in copper CNC machining for electrical wiring, conductive components, and electrical busbars due to its outstanding electrical performance.

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 69-365 MPa | 5-50 % | 65-90 HB | 8.89 g/cm³ |

Get Metal Copper Parts with Zhongde

FAQs of Copper Materials

View our FAQ center for more questions.

Can copper be used for electrical wiring?

Copper is commonly used for electrical wiring due to its excellent electrical conductivity and corrosion resistance.

What are the benefits of using copper in plumbing?

Stainless steel is available in a range of surface finishes, including brushed, polished, matte, and textured finishes, each offering distinct aesthetic and functional characteristics.

What factors affect the conductivity of copper?

The conductivity of copper is primarily influenced by its purity, temperature, grain size and structure, alloying elements, and mechanical stress. Higher purity copper generally exhibits better conductivity, while temperature changes and mechanical stress can affect conductivity levels. Additionally, factors like grain size and alloying elements play a role in modifying copper's conductivity.

It is easy to fill the form.

Better Quality, Faster Delivery

From design to final parts, from rapid prototyping to mass production, Zhongde's one-stop service meets your needs.

Upload your design drawing and all uploads are secure and confidential!

Upload your design drawing and all uploads are secure and confidential!