Home » Bronze

Bronze

Material Type

Metal

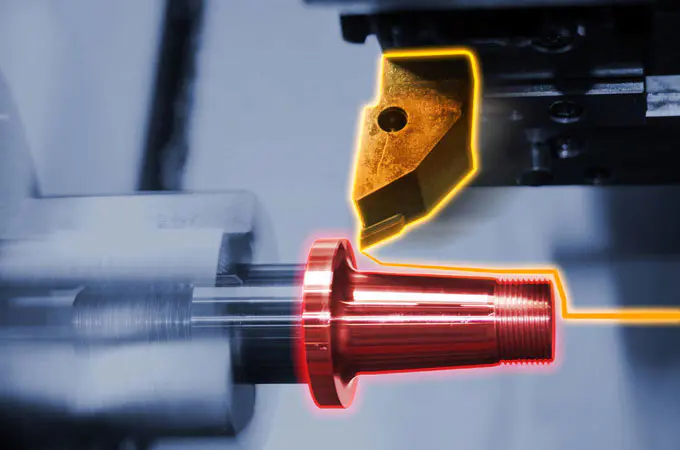

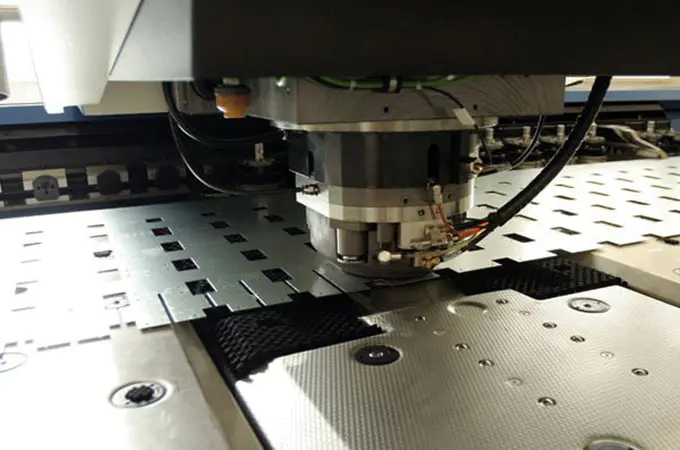

Process Compatibility

CNC Machining, Metal Stamping

List of Metal Material

List of Plastic Material

List of Elastomer & Rubber

Customized Bronze Fabrication Solution

Start A New Project Right Now!

Bronze Description

Price

Strength

Excellent wear resistance, good corrosion resistance, low friction, suitable for heavy-load parts

Weakness

Common Application

Bearings, bushings, gears, marine hardware, electrical connectors

Available Bronze Materials

C93200 (Bearing Bronze)

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 200–380 MPa | 10–30% | 60–110 HB | 8.7 g/cm³ |

C95400 (Aluminum Bronze)

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 450–620 MPa | 15–25% | 150–220 HB | 7.6–7.9 g/cm³ |

C83600 (Phosphor Bronze)

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 300–480 MPa | 10–25% | 80–130 HB | 8.8 g/cm³ |

Get Custom Bronze Parts with Zhongde

FAQs of Bronze Materials

What is the typical hardness and density of bronze alloys used in fabrication?

Bronze alloys generally have hardness ranging from 60 to 220 HB and density around 7.6 to 8.8 g/cm³, depending on the specific alloy like C93200 or C95400.

How does the machinability of bronze compare to other metals?

Bronze, especially free-machining types like C93200, offers excellent machinability with less tool wear compared to steel, making it cost-effective for complex parts.

Which bronze alloys are commonly used for machining?

Common alloys include C93200 (bearing bronze), C95400 (aluminum bronze), and C83600 (phosphor bronze), each offering specific strengths for different applications.

It is easy to fill the form.

Better Quality, Faster Delivery

Upload your design drawing and all uploads are secure and confidential!