Home » Alloy Steel

Alloy Steel

Material Type

Metal

Process Compatibility

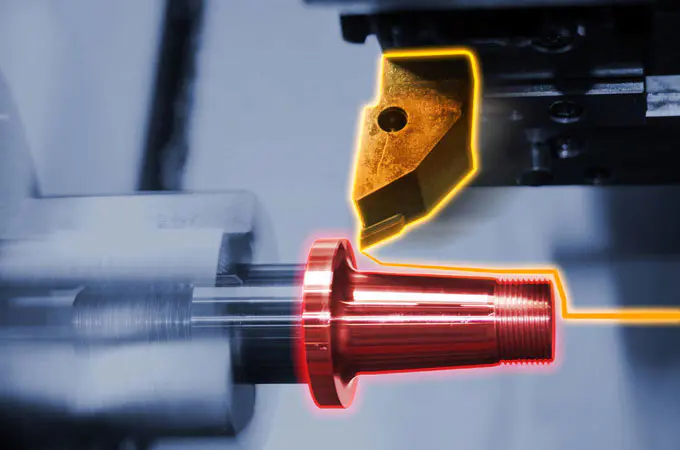

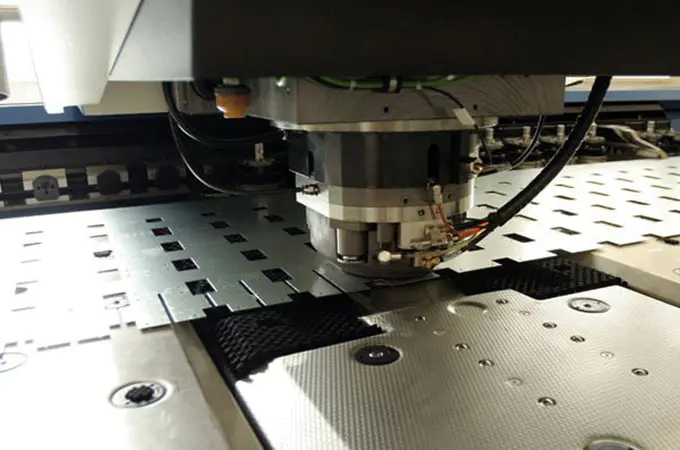

CNC Machining, Metal Stamping

List of Metal Material

List of Plastic Material

List of Elastomer & Rubber

Customized Alloy Steel Fabrication Solution

Zhongde offers precision alloy steel machining and stamping for both prototypes and large-scale production. With high strength and durability, we deliver tight-tolerance parts such as gears, shafts, and precision metal components on time and to your specifications.

Start A New Project Right Now!

If alloy steel is the right material for your application, simply send us your drawings or samples.

Alloy Steel Description

Price

$$$$$

Strength

Excellent tensile strength, wear resistance, and toughness; performs well under heavy loads and high stress

Weakness

Heavier than aluminum or brass; may require protective coatings to prevent corrosion

Common Application

Automotive components, machinery parts, gears, shafts, fasteners

Available Alloy Steel Materials

4140 Alloy Steel (Chromium-Molybdenum Steel)

4140 is a low-alloy steel known for high tensile strength, good toughness, and wear resistance. It performs well in demanding mechanical environments and is suitable for both machining and stamping.

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 655–950 MPa | 20–25% | 200–300 HB | 7.85 g/cm³ |

4340 Alloy Steel (Nickel-Chromium-Molybdenum Steel)

4340 offers ultra-high strength, excellent toughness, and superior fatigue resistance. It is often chosen for critical components that require durability under high stress.

| Tensile Strength | Elongation at Break | Hardness | Desnsity |

|---|---|---|---|

| 745–1180 MPa | 18–22% | 217–302 HB | 7.85 g/cm³ |

Get Custom Alloy Steel Parts with Zhongde

FAQs of Alloy Steel Materials

View our FAQ center for more questions.

Is alloy steel suitable for machining and stamping?

Yes. Alloy steels such as 4140 and 4340 are commonly used for CNC machining and stamping. They offer good dimensional stability and can achieve tight tolerances.

Does alloy steel need surface treatment to prevent corrosion?

Most alloy steels are not naturally corrosion-resistant and usually need coatings like plating, painting, or heat treatment to improve durability in harsh environments.

Can Zhongde produce custom alloy steel components based on my drawings?

Yes. We can manufacture prototypes or high-volume alloy steel parts according to your 2D drawings or 3D models, ensuring precise dimensions and consistent quality.

It is easy to fill the form.

Better Quality, Faster Delivery

From design to final parts, from rapid prototyping to mass production, Zhongde's one-stop service meets your needs.

Upload your design drawing and all uploads are secure and confidential!

Upload your design drawing and all uploads are secure and confidential!