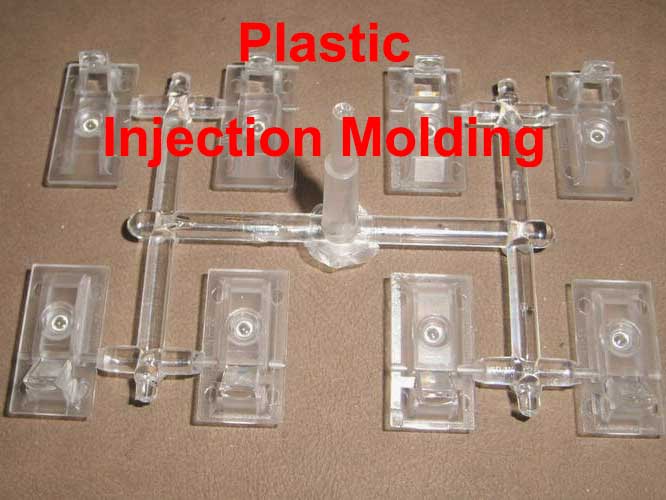

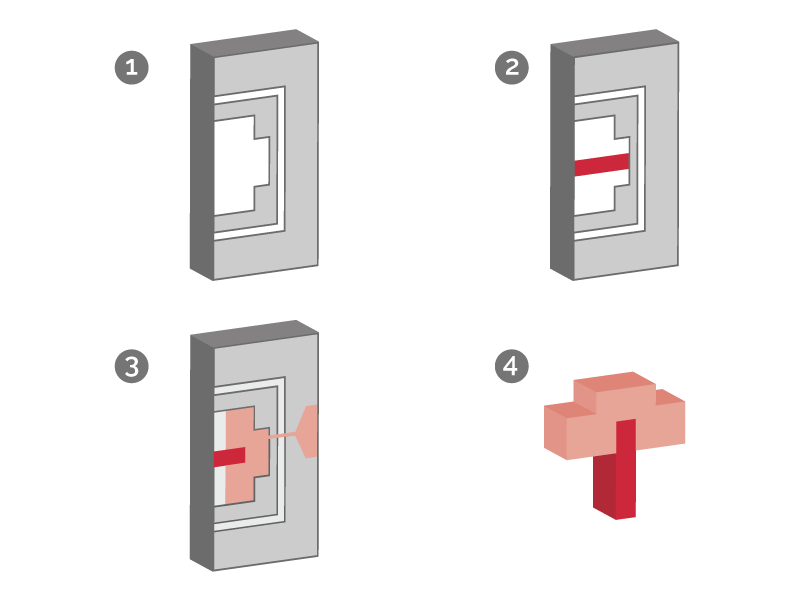

What are Injection Molding Sprue: Types, Design, and Process Optimization

The injection molding sprue act as the channel for plastic to enter the mold cavities. However, the placement and design of the sprue can greatly affect the finished part’s quality and the molding process efficiency. Let’s delve into sprues in injection molding and important considerations for their design and use. What is a Sprue in […]

What are Injection Molding Sprue: Types, Design, and Process Optimization Read More »