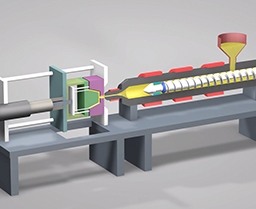

After years of experience in custom injection mold tooling service, we have summed up some mold processing tips, I hope it will be useful to everyone!

1. Allowance must be reserved when processing injection mold toolings

The injection mould tool manufacture workpiece needs heat treatment processing. Before heat treatment, add 0.25mm of grinding machine allowance on one side to the shape and size of the material. The mold core and inserts need to be CNC roughed, leaving 0.2mm on one side, and one side for rough milling on the fitter milling machine. 0.3-0.5mm, after wire cutting, a grinder is required to process the workpiece, leaving 0.03mm on one side of the profile, and 0.1mm on one side of the fitter milling machine for rough milling of the shape, after CNC finishing and electric pulse, it needs to be mirror polished, leaving 0.03mm on one side .

2. Principles of CNC injection mold tooling

The core and inserts need to be roughed by CNC, and leave a margin of 0.2mm on one side. For workpieces that need CNC finishing after heat treatment, if the appearance of the product allows, CNC can be finished in place, and CNC processing is preferred. The finishing is done by electric pulse machining.

3. The principle of the injection mold tooling CNC electrode removal

The core of the injection molding cavity should first disassemble the main electrode of the appearance, then disassemble other electrodes, and finally disassemble the local electrode; the electrode of the appearance of the front model should be given priority to the overall processing, and for the places that cannot be processed by CNC, use wire cutting to process the corners to make the front mold The appearance surface is complete and there is no machining trace, the reinforcing ribs, ribs and columns with little difference in the depth of the rear model can be processed together to make an electrode as much as possible. The ribs with the deeper surface of the front model should be used as inserts and should be used as an electrode side strike separately to avoid Prevent electric pulse carbon deposition, the electrode of the rear model needs to be cleaned by wire cutting after milling as much as possible. If necessary, the electrode should be disassembled or cut directly by wire, the distance between the ribs, ribs or columns of the front model is greater than 35mm, which should be done separately to save copper material.

The above content is the little skills you need to know when processing injection mold toolings. If you need more knowledge, you can follow us. As one of the best injection molding manufacturers in China, our company provides high-quality, low-cost plastic and rubber injection molding parts to global customers.

Zhongde (Beijing) Machinery Equipment., Ltd’s scientific injection molding process helps you reduce design risks, with the support of many senior project managers and engineering experts, communicate in all project stages from design to production, minimize costs, if you need injection molding services, welcome to consult us.