Injection Molding is the Ideal Method of Processing

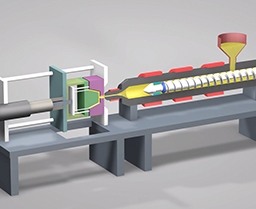

Injection molding is the ideal method of processing. Why? We compared injection molding with several other molding methods, let’s take a look. Ⅰ. Comparison of precision plastic injection and extrusion molding Injection molding is one of the most popular methods for forming 3D shaped plastics. It is based on the method of molten die casting […]

Injection Molding is the Ideal Method of Processing Read More »