Injection Molding Gate Design: Enhancing Plastic Manufacturing

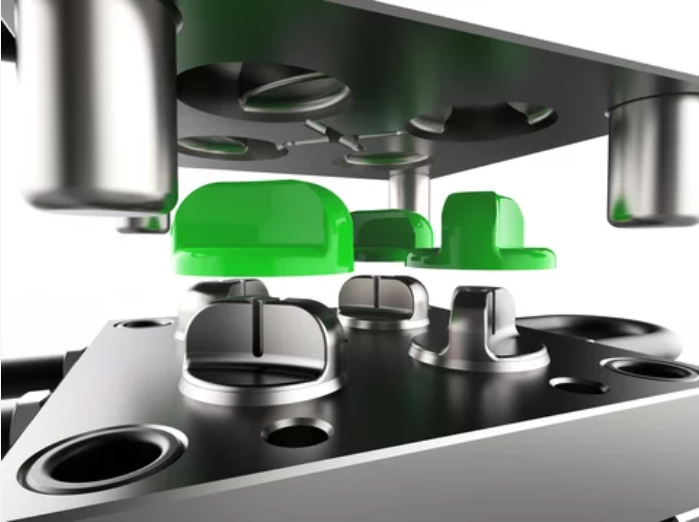

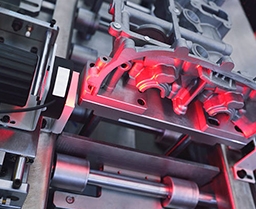

Injection molding is a popular method of creating plastic parts. Molten plastic is injected into a mold cavity, allowed to cool and solidify, and the final item is ejected. The gate is an essential part of the injection molding process. The injection molding gate is the point of entrance for the molten plastic into the […]

Injection Molding Gate Design: Enhancing Plastic Manufacturing Read More »