Plastic injection molding defects refer to the flaws caused in the manufacturing process. Plastic injection molding defects can result from various factors, including issues with the material, design flaws, or manufacturing process issues.

Product failure, increased production costs, and ultimately dissatisfied customers are all possible outcomes of these flaws. To produce products made of high-quality plastic that meet the desired specifications, plastic injection molding defects must be identified and addressed.

Warping, sink marks, flashes, voids, short shots, and dimensional irregularities are all common injection molding flaws. These errors can be caused by a variety of sources, including design flaws, material concerns, or manufacturing process issues. Identifying and correcting these flaws is critical for developing high-quality plastic goods that match the necessary specifications and performance standards.

The following are the most common defects in plastic injection molding with causes and solutions. These defects can occur due to serval reasons, which can be corrected to achieve the best results.

1: Flash

Flash is an injection molding flaw that arises when an excess of plastic leaks out of the mold cavity and hardens on the object’s surface. This extra plastic material, known as a flash, results in a thin coating or protrusion on the surface of the finished product.

Causes of flash defects

Flash defects can be caused by several factors such as:

- High injection pressure

- Insufficient clamping force

- Worn-out molds

Flash can ruin a product’s aesthetic appeal and usability, and increasing post-processing expenses to repair the mold lowers productivity. This results in dissatisfied customers.

How to solve flash defects:

The following are some steps that can help solve flash defects in injection molding:

- By implementing an increased clamping force, we can help reduce flash defects by preventing the mold from leaking materials.

- Optimizing the injection pressure and speed can help decrease the amount of plastic material that leaks from the mold cavity and solidifies on the part’s surface.

- It is essential to regularly inspect and replace damaged molds that may end up contributing to flash defects.

- By adjusting the cooling system to an optimal degree, we can help reduce the material’s leakage and solidification from the mold.

- Mold release agents can help prevent the plastic material from sticking to the mold cavity and reduce the risk of flash defects.

- Reviewing and optimizing the design of both the product and the mold can help minimize the risk of flash defects.

Read more details about injection molding flash on our blog: Dealing with Injection Molding Flash: Causes, Prevention, and Removal

Sink marks

Sink mark defects are common plastic injection molding defects that occur when the surface of the plastic product appears sunken or indented due to uneven cooling rates during the molding process.

Causes of sink marks

Sink marks can occur as a result of the non-uniform cooling rate of the plastic. This causes some areas to shrink faster than others. As a result, the final product has an uneven surface with visible depressions and sink marks.

Sink marks are also caused by defects in the mold such as small sprue, runner, or/and gate, improper location of the gate, and inappropriate temperature of the mold surface.

How to solve sink marks

To solve sink mark defects, the following steps can be taken:

- Increasing the packing pressure can help ensure that the plastic material fills up the mold cavity completely. This reduces the risk of sink marks.

- By increasing the holding time, we can allow the plastic material to cool more uniformly, reducing the chance of sink marks.

- Increasing the mold temperature to ensure slower cooling of the plastic material may be beneficial.

- The gate location can affect how the plastic material flows and cools, so modifying the gate location can help reduce the occurrence of sink marks.

- Reducing the thickness of the affected area by implementing design changes can help decrease the risk of sink marks.

Read more details about injection molding sink mark in our blog: Dealing with Injection Molding Sink Marks: Causes and Prevention

3. Warpage

Warpage is a common injection molding defect. A warped final product is unconventionally bent or twisted out of shape, making it unsuitable for use or aesthetically unappealing.

Causes of warpage:

This defect occurs as a result of heating, uneven cooling, or dampening, causing different parts of the product to shrink or expand at different rates. This uneven shrinkage can cause the product to warp or bend, leading to warpage defects.

How to solve warpage defects:

To solve warpage defects, the following steps can be taken:

- Increasing the mold temperature can help reduce the cooling rate of the plastic material and ensure that it cools and solidifies more evenly.

- Increasing the cooling time allows the plastic material to cool more slowly, reducing the risk of warpage defects.

- Optimizing the gate location can help reduce the risk of warpage defects.

- Adjusting the packing pressure can help ensure the plastic material fills the mold cavity evenly, reducing the risk of warpage.

- Design modifications such as reducing the thickness of affected areas or adding ribs or other structural elements can help reduce the occurrence of warpage defects.

Read more methods to solve injection molding warpage defects: Deal with Warpage in Injection Molding: Causes and Prevention

4: Burn marks

Burn marks are a common injection molding defect resulting in severe product quality loss. Burn marks are stains on the finished molded object’s surface, often dark reddish-brown or black streaks.

Causes of burn marks

Burn markings emerge during the molding process as a result of excessive heat. They develop as a result of the plastic material’s degradation and discoloration brought on by prolonged exposure to high temperatures. Other than that, they can also be caused by:

- Fast injection speed

- High melt temperature

- Restrictive flow path

- High screw speed

How to solve burn marks:

To solve burn mark defects, the following steps can be taken:

- Burn marks are more likely to appear when the plastic substance is heated up quickly due to a fast injection speed. Reduced injection speed may help reduce the chance of burn marks.

- Reducing the melt temperature can help reduce the risk of overheating the plastic material.

- Increasing the cooling time

- Increase mold temperature

- Dirty or worn molds can contribute to burn marks, so it’s essential to regularly inspect and clean the molds to ensure they are in good condition.

5: Short shots

A short shot is when a mold cavity is only partially filled, which causes an unfinished item to be produced since the plastic doesn’t have enough fluidity.

Causes of short shots:

Here are the main causes of short-shot defects in injection molding:

- Inappropriate injection pressure

- Insufficient plastic material being injected into the mold

- Inappropriate mold design, including flow imbalance and poor venting

- Inappropriate molding processes, such as low barrel temperature, slow injection speed, short injection time, and oversupply of plastic.

How to solve short shot defects:

To solve short-shot defects, the following steps can be taken:

- Increase injection pressure

- Increase injection speed

- Increase the holding time

- Optimizing the gate location may help reduce the occurrence of short shots since it may affect how the plastic material flows and fills the mold cavity

Read more solutions for injection molding short shots: How to Deal with Injection Molding Short Shots: Causes and Solutions

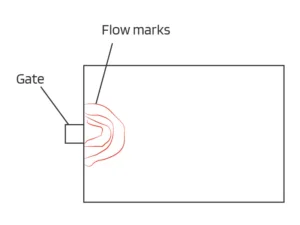

6: Flow lines

Flow lines is a common injection molding flaws that appear as lines or streaks on the plastic part’s surface and indicate a change in the plastic material’s flow pattern. These defects appear on the part’s surface when the plastic material flows too slowly or too quickly, causing it to cool and solidify at varying speeds and leaving visible lines.

Causes of flow lines:

Flow lines can result from deficiencies in the material, molds, and injection molding process itself.

Mold-related causes:

- Low mold temperature

- Insufficient Sizes of the Sprue, the Runner, and the Gate

- Insufficient venting

Material-related causes:

- Poor fluidity

- Inappropriate application of lubricant

Injection molding process-related causes:

- Low nozzle temperature

- Low barrel temperature

- Low holding pressure

- Insufficient processing time

How to solve flow line defects

To solve flow line defects, the following steps can be taken:

- Increasing the injection speed

- Increasing the holding pressure

- Increasing the mold, nozzle, and barrel temperature

- Modifying the gate design

- Certain plastic materials are more prone to flow lines than others, so selecting a plastic material that is less prone to flow lines can help reduce the occurrence of this defect.

- Checking and cleaning the mold

7: Gloss Difference

For injection molding plastic products, the difference in gloss on the surface of the textured product is most obvious. Even if the surface of the mold is very uniform, an irregular gloss may appear on the product. That is to say, the mold surface effect of some parts of the product is not well reproduced.

Causes of gloss difference

As the distance of the melt from the gate gradually increases, the injection pressure of the melt gradually decreases. If the distal end of the gate of the product cannot be filled, the pressure there is the lowest, so that the texture of the mold surface cannot be correctly copied to the surface of the product. Therefore, the area where the cavity pressure is the greatest (half of the fluid path from the gate) is the area where the gloss difference is the least.

How to solve gloss difference:

To change this situation, the following steps can be taken:

Increasing the melt and mold temperature or increasing the pressure, while increasing the holding time can also reduce the difference in gloss.

Improving custom plastic parts design.

Conclusion for Injection Molding Defects

To sum up, injection molding is a common and efficient manufacturing technique used to create a variety of plastic items. Injection molding is not above its difficulties, though, as errors can happen that affect the end product’s performance and quality.

We did an overview of various prevalent injection molding flaws, such as flash, sink marks, warpages, burn markings, short shots, and flow lines. And we have discussed their solutions. Manufacturers can create high-quality injection molded goods that satisfy the required specifications and performance standards by understanding the cause of these problems and taking the necessary steps to prevent or address them.