Learn about the Undercuts in Injection Molding Design for Custom Parts

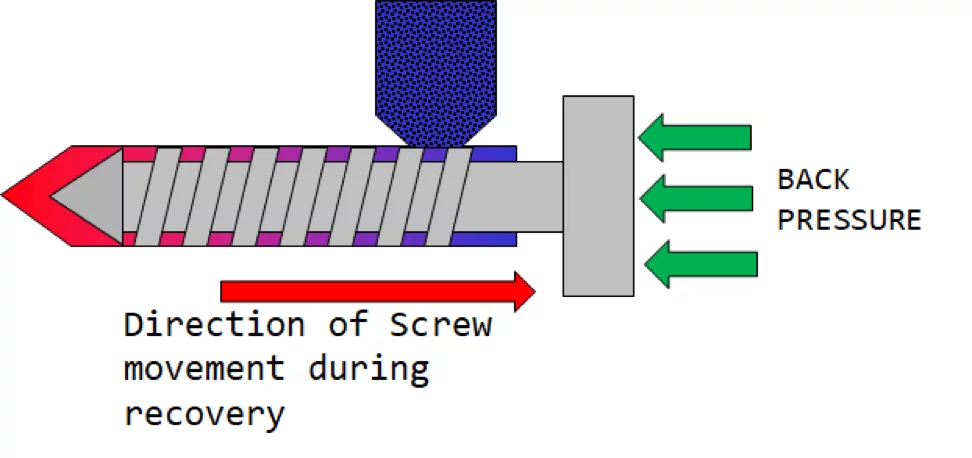

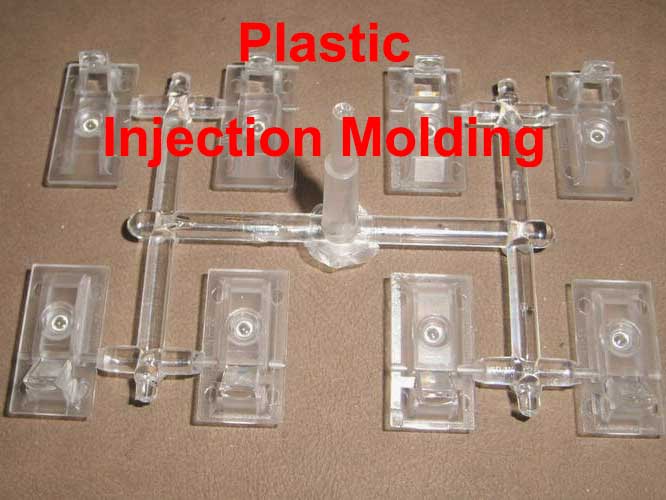

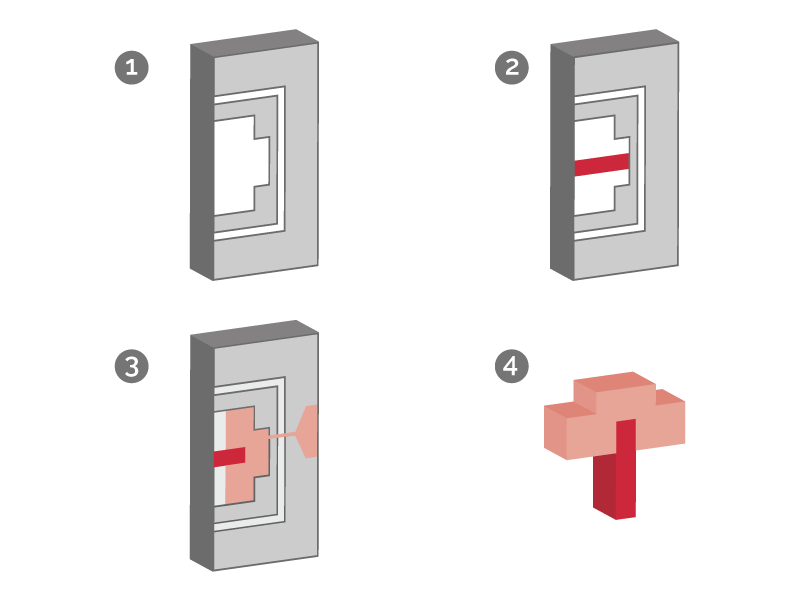

Undercut in injection molding is a design that allows the creation of parts with complex shapes. However, these complex designs often present a challenge – molded parts with undercuts are difficult to remove from the mold. The undercuts also increase the complexity and associated costs of a project. In this article, We will explore what […]

Learn about the Undercuts in Injection Molding Design for Custom Parts Read More »