In the ever-evolving landscape of manufacturing, innovation is the key to staying ahead of the curve. 2-shot injection molding( two-shot injection molding) also named double shots injection molding, has not only streamlined manufacturing processes but has also opened doors to new possibilities in product design and functionality.

In this post, we will delve deep into the world of 2-shot injection molding, exploring its concepts, its advantages, and the diverse array of applications that have catapulted it to the forefront of modern manufacturing. Join us on this journey as we unravel the intricacies of 2-shot molding and discover why it has become a game-changer in the manufacturing industry.

What is 2-Shot Injection Molding?

2-shot injection molding is an advanced manufacturing process that involves injecting two different materials into a single mold during a single cycle. The fundamental principle behind this technique is to create a multi-material or multi-color component in a single, efficient operation. Instead of using separate molds or post-production assembly, 2-shot molding fuses different materials or colors together within the mold, resulting in a finished product with enhanced functionality and aesthetics.

The Process of 2-Shot Injection Molding:

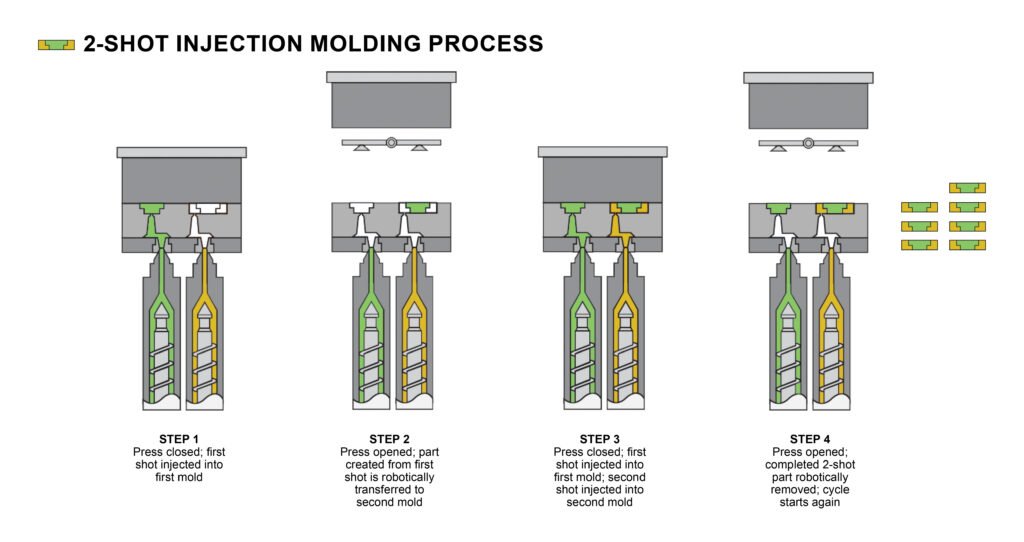

2-shot injection molding is a precise and efficient process that involves several distinct steps. Here’s a step-by-step overview of how it works:

1. Mold Preparation:

Start by preparing a specialized 2-shot mold with multiple cavities for different materials/colors.

2. First Shot (First Material):

Load rigid material into the first injection unit. Inject it into designated mold cavities to form the base structure.

3. Cooling and Solidification:

After the first shot, the mold remains closed to allow the first material to cool and solidify. The cooling time is critical to ensure the material is set properly.

4. Second Shot (Second Material):

The second material, typically a soft or elastomeric plastic, is injected into specific areas of the mold. The two materials bond together during this stage to create a cohesive product.

5. Cooling and Final Solidification:

After the second shot, the mold closes again, and the entire part undergoes a final cooling and solidification process.

6. Ejection and Post-Processing:

Once the part has fully solidified, the mold opens, and the finished 2-shot molded product is ejected from the mold. Depending on the specific product requirements, post-processing steps such as trimming, assembly, or quality control checks may be performed.

Advantages of 2-Shot Injection Molding:

2-shot injection molding offers a range of advantages that make it an attractive choice for manufacturers across various industries.

Reduced Manufacturing Steps:

One of the standout advantages of 2-shot molding is the consolidation of manufacturing steps. By injecting two materials in a single cycle, it eliminates the need for secondary assembly or bonding, reducing labor costs and production time.

Cost Savings:

Using 2-shot molding often means less waste since materials are precisely injected where needed, minimizing excess material and scrap.

Enhanced Aesthetics:

2-shot molding allows for precise and seamless integration of different materials or colors. This results in a high-quality finished product with smooth transitions between components.

Design Flexibility and Functional Integration:

2-shot molding offers greater design freedom. Manufacturers can combine materials with varying properties, such as rigidity and flexibility, in a single product. For example, a product might combine a hard, durable material with a soft, grippy material for ergonomic handles.

Considerations of 2-Shot Injection Molding

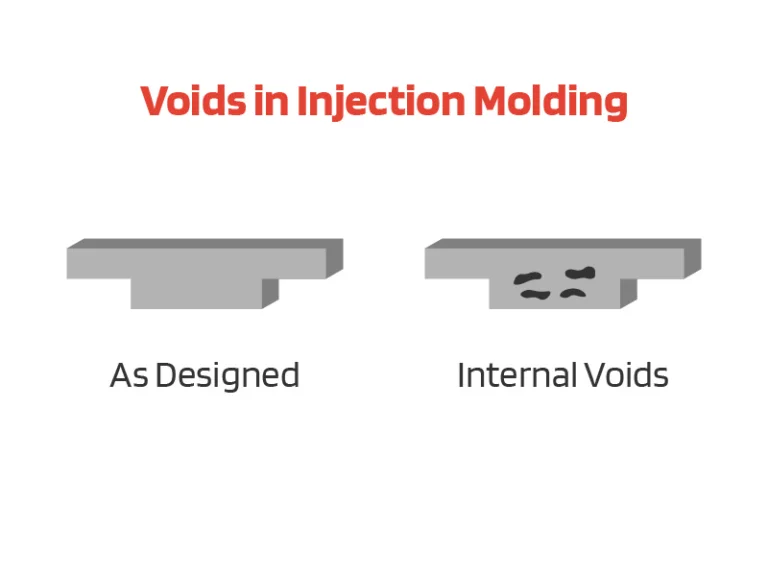

One challenge in 2-shot injection molding is ensuring that the two materials bond effectively. Proper mold design and material selection are crucial to achieve strong adhesion between the layers.

Material Selection

Material Compatibility: Ensure that the two materials you intend to use in the 2-shot process are compatible. They should bond well when injected sequentially. Compatibility testing is essential to confirm this.

In addition to material compatibility, there are other considerations in the selection of materials. The choice of materials depends on the specific properties and functions required for the product. For example:

- The first shot material may be a rigid engineering plastic for structural support.

- The second shot material may be a soft elastomer for grip or cushioning.

Material compatibility, adhesion, and shrinkage rates must be considered to ensure a seamless and durable final product.

The 2-Shot Injection Molding Mold Design

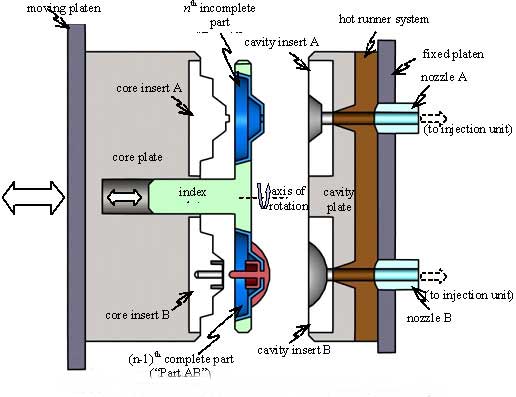

In 2-shot injection molding with a rotary plate, there’s a special plate that can spin on one side of the molding machine. It helps the mold move around during the molding process.

The mold itself has two sets of ejector plates and two runner systems. The part that moves during molding is called the movable half.

The mold has a rotary plate built-in, actuated by hydraulics or a rack system. With a rotary-platen mold, it is critical to have locators on the mold and the machine platens to ensure that it is exactly on the center of the rotary platen. If the mold is not exactly on center, you will have alignment issues; when the mold rotates 180° it can damage the leader pins, bushings, and shutoffs. It is also important to consider tonnage with part surface area. In most cases your cavities will be off-center—first shot on one half and second shot on the other half—so you will not have full advantage of the machine tonnage to compensate for the cavity plastic pressure.

We also need to make sure the first-shot cavity has support against the second-shot cavity pressure. At times, ribs or undercuts are needed to hold the first shot in place to prevent flash and deformation. Make sure the hydraulic cylinders actuating the cores are robust enough to resist the cavity plastic pressure or the products will flash and narrow process windows.

Applications of 2-Shot Injection Molding

2-shot injection molding finds widespread use in several industries due to its ability to create complex, multi-material components efficiently. Here are some key industries where 2-shot molding is commonly applied.

1. Automotive Industry:

Car interiors often utilize 2-shot molding to create soft-touch surfaces for dashboards, armrests, and steering wheels. This improves comfort and aesthetics while maintaining structural integrity.

2. Medical Devices:

Medical equipment often incorporates grips made using 2-shot molding. These grips provide a secure and comfortable hold, critical in surgical instruments and diagnostic devices.

3. Consumer Electronics:

In consumer electronics, remote controls benefit from 2-shot molding to create buttons with a tactile outer surface for user comfort and a rigid inner structure to ensure button durability.

4. Consumer Products:

Toothbrush manufacturers use 2-shot molding to create handles that combine a hard plastic core with a soft, textured grip. This design improves ergonomics and user experience.

5. Electronics and Connectors:

Wearable technology benefits from 2-shot molding by creating bands with a comfortable, skin-friendly surface and a rigid inner structure to house electronic components.

2-Shot Injection Molding vs Overmolding

2-shot injection molding and overmolding share similarities in that they both involve the use of multiple materials in the injection molding process to create a single, integrated product. You can read more about overmolding here. However, there are distinctions between the two processes.

1. Number of Shots:

2-Shot Injection Molding: This process specifically involves two distinct shots of different materials injected into the same mold during a single molding cycle. The two materials are often chosen to serve different functions in the final product.

Overmolding: Overmolding can involve more than two shots. It typically begins with a base or substrate component (the first shot) and then adds one or more additional shots (overmolded layers) to enhance properties or provide additional features.

2. Material Purpose:

2-Shot Injection Molding: The primary purpose of 2-shot molding is to combine different materials to achieve a specific combination of properties, functions, or aesthetics.

Overmolding: Overmolding is often used to add a layer of material for functional purposes, such as improving grip, providing cushioning, or adding sealing. It can also be used for aesthetic enhancements.

3. Process Complexity:

2-Shot Injection Molding: While it involves two materials, 2-shot molding is typically more straightforward than multi-step overmolding processes. It aims to create a cohesive product with two materials efficiently in a single molding cycle.

Overmolding: Overmolding may involve multiple shots and complex sequences, which can include different materials and molds for each layer.

Conclusion

In conclusion, our exploration of 2-shot injection molding has illuminated its significance in modern manufacturing, revealing a technique that offers substantial benefits to a wide range of industries. 2-shot injection molding stands as a cornerstone of innovation in modern manufacturing. Its ability to create complex, multi-material components in a single cycle not only reduces costs but also opens doors to creative and functional product design. This manufacturing technique aligns with the demands of today’s consumers who seek high-quality, aesthetically pleasing, and functional products.

Choose A Reliable Manufacturer for Your New Project!

- All information and uploads are secure and confidential