Insert molding is a manufacturing process that we often encounter in our daily live. From the smartphones we use daily to the electrical components that power our homes, many of these essential items are created through a process called insert molding. Insert molding allows manufacturers to combine plastic and metal parts into a single, durable component. In this article, we’ll dive into the details of insert molding, exploring its benefits, applications, design guidelines and compare with other modern manufacturing process.

What is Insert Molding?

Insert molding is an injection molding technique that incorporates inserts, often metal, into an injection-molded component. The process entails placing the insert inside the mold cavity before injecting molten plastic. As the plastic cools and solidifies, it firmly encapsulates the insert, transforming it into an integral part of the final product.

Insert moulded excels in the production of components characterized by their strength, durability, and low weight. Due to these attributes, a wide range of industries has embraced this method to manufacture robust and lightweight parts efficiently.

Zhongde is an on-demand manufacturer in China and offers custom insert molding services. If you want to start an insert molding project, Zhongde would be your reliable partner.

Common Insert Materials

Material selection of inserts for injection molding depends on the specific requirements of the final product. Common injection molding inserts material included:

- Metals: Such as brass, stainless steel, or aluminum for added strength and durability.

- Plastics: Thermoplastic materials compatible with the injection molding process.

- Ceramics: Ideal for applications requiring high heat resistance or electrical insulation.

- Electronics: Components like sensors or connectors can also be integrated as inserts.

A Comprehensive Guide to Types of Rivets and Applications

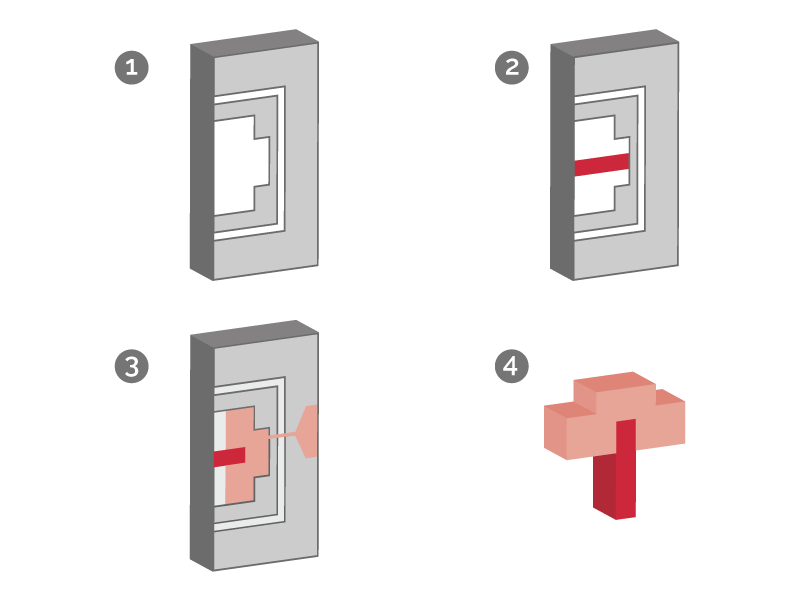

Insert Moulding Process

Load Inserts into Mold:

- Automated Load: In some cases, automated machinery is used to precisely place the inserts into the mold cavities. This ensures accuracy and consistency. Automated machines are fast and can produce more parts per hour. So, the method is suitable for high-volume production. However, the initial capital is high.

- Load by Hand: For certain products or prototypes, inserts may be manually loaded into the mold. Skilled operators carefully position the inserts in the desired locations within the mold. This method has lower initial capital and it is popular for low-volume production.

Inject the Molten Plastic into the Mold:

Plastic insert molding process occurs under high pressure, ensuring that the plastic flows evenly around the inserts, filling all cavities.

Open the Mold and Remove the Molded Part:

Once the plastic has sufficiently cooled and solidified, the mold is opened. This step can be automated or done manually, depending on the equipment used. The molded part, now firmly integrated with the inserts, is carefully removed from the mold.

Separate the Molded Part from the Sprue:

In the molding process, excess plastic material, called sprue or runners, is often created as a result of the injection. These must be separated from the final molded part. This can be achieved through various methods, including trimming or cutting.

Post-Processing:

Depending on the specific requirements of the product, post-processing steps may be necessary. This can include additional machining, surface finishing, or quality inspections to ensure the part meets the desired specifications.

Insert Molding Design Guide

Avoid Sharp Corners:

Sharp corners can create stress concentrations, leading to part failure or cracking. Design parts with rounded edges or fillets to distribute stress more evenly. Maintain uniform thickness when designing the corners. Ensure that the radius inside is not less than half of your wall thickness. The outer radius should also be the addition of the internal radius and the wall thickness.

Optimize Draft Angles:

The molded parts can be difficult to remove from the mold due to the shrinkage. Incorporate draft angles on vertical surfaces to facilitate easy part ejection from the mold. Typically, a draft angle of 1 to 2 degrees is sufficient.

Draft angle is a design that ensures smooth ejection of the molded part from the mold cavity, minimizing defects and streamlining production.

Enhancing Part Quality by Optimizing Injection Molding Draft Angle Design

Consider Metal Inserts Bonding:

If your inserts are made of metal, consider surface treatments or coatings to enhance bonding with the plastic material. Proper bonding is crucial for part strength.

Suitable Boss Diameter:

Bosses are usually used for the shaft-hole fit of two plastic products, or for the assembly of self-tapping screws. When designing bosses (protrusions or mounting points), consider their diameter to ensure adequate strength and durability. When BOSS is used to assemble self-tapping screws, its inner hole should be 0.1-0.2 smaller than the thread diameter of the self-tapping screws on one side so that the screws can be locked.

Use Durable Resins:

Select plastic resins that are durable and compatible with the inserts and the intended application. Consider factors like chemical resistance, temperature tolerance, and UV stability.

Wall Thickness of the Mold:

Ensure that the mold’s wall thickness is appropriate to withstand the pressures and stresses of the injection molding process. A well-designed, sturdy mold is essential for consistent production.

Advantages of Insert Molding in Manufacturing

Enhanced Part Strength:

By integrating inserts made of materials such as metals or ceramics, insert molding significantly improves the strength and durability of the final product. This is particularly important in industries where robust components are essential.

Reduced Assembly Time:

Traditional assembly methods often require multiple steps to incorporate inserts into plastic parts. Insert molding combines these steps into one, reducing assembly time and increasing production efficiency.

Reduce Size and Weight:

Insert molding enables the creation of lightweight yet strong components. By integrating inserts made from materials like lightweight metals or specialized plastics, manufacturers can design products with reduced overall weight.

Variety of Designs:

Insert molding allows for the creation of complex and intricate product designs that would be challenging to achieve through other means. This flexibility is especially valuable in industries with unique or demanding design requirements.

Improved Electrical and Thermal Properties:

When using inserts made of specialized materials, insert molding can enhance a product’s electrical insulation or thermal conductivity, making it suitable for a wide range of applications.

Insert Molding Common Issues and Solutions

Poor Insert Adhesion:

Sometimes, inserts may not bond well with the plastic, leading to weak connections or insert displacement during molding.

Solution: Ensure proper surface treatment of inserts (e.g., cleaning, priming, or roughening) to enhance adhesion. Adjust injection parameters, including temperature and pressure, to optimize bonding.

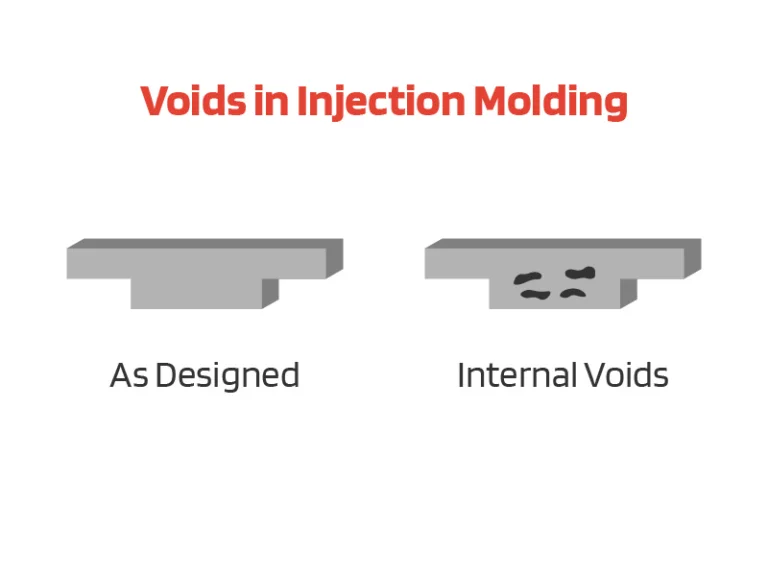

Warping or Sink Marks:

Uneven cooling can result in warping or sink marks on the molded part’s surface.

Solution: Optimize cooling and cycle times to achieve uniform temperature distribution within the mold. Consider using conformal cooling channels to improve cooling efficiency.

Insert Alignment Issues:

Misalignment of inserts within the mold can lead to improper positioning or asymmetrical parts.

Solution: Implement precise insert loading mechanisms or automation to ensure consistent placement. Verify that mold cavities are accurately designed to accommodate inserts.

Insert Damage:

Delicate or fragile inserts may be susceptible to damage during the molding process.

Solution: Design molds with features that protect the inserts during injection. Employ gentle mold opening and closing to minimize stress on the inserts.

Resin Compatibility:

The choice of plastic resin must be compatible with both the inserts and the molding process.

Solution: Conduct material compatibility testing to select the right resin for the application. Consider materials with suitable melt temperatures and flow properties.

Applications of Insert Molding

Insert molding finds extensive use in various industries due to its ability to create strong, multi-material components and enhance product design and functionality. Here are some insert molding examples in various industries:

- Automotive Industry: Automotive connectors, sensor housings, dashboard components. Improved strength and durability, reduced assembly steps, and compact designs for automotive parts.

- Electronics and Consumer Goods: Electrical connectors, smartphone cases, remote control buttons. Precise integration of components, sleek and compact designs, and enhanced functionality for electronic devices.

- Telecommunications: Fiber optic connectors, network cable components. Precise alignment of optical components, reduced size, and improved performance for telecom products.

Insert Molding vs Overmolding

Insert molding and over-molding are both specialized techniques used in injection molding, but they have distinct purposes and processes.

Insert Molding:

Insert molding involves placing pre-fabricated components (inserts) into the mold, and then molten plastic is injected to bond with and encapsulate the inserts. Insert molding is a one-step molding process. The primary purpose is to create a single, integrated part with added strength, reduced assembly steps, and improved functionality.

Overmolding:

Overmolding involves molding a layer of plastic over an existing part or substrate (which can be another plastic part or a different material like metal). Overmolding is a two-step process. The primary purpose is to add a protective or functional layer to the existing part, improve grip, or enhance aesthetics.

All You Need to Know About Overmolding

Key Differences

| Feature | Insert Molding | Overmolding |

|---|---|---|

| Process Type | Single-step (one-shot) | Multi-step (two or more shots) |

| Material Use | Typically integrates metal inserts | Combines different types of materials |

| Complexity | Generally simpler tooling requirements | More complex tooling and setup |

| Cost Efficiency | More cost-effective for lower volumes | Generally better for high-volume production due to efficiency |

| Bonding Mechanism | Encapsulation of inserts | Layering of materials with potential chemical bonding |

Insert Molding vs Injection Molding

Insert molding is a more specialized process that integrates additional components into the molded part, enhancing its functionality and strength. In contrast, traditional injection molding focuses on producing parts solely from plastics.

Key Differences

| Feature | Insert Molding | Injection Molding |

|---|---|---|

| Process Complexity | Involves inserting components before injecting plastic | Typically involves only injecting plastic |

| Material Combination | Combines plastics with metal or other materials | Primarily uses thermoplastics |

| Assembly Requirements | Reduces need for post-molding assembly | May require additional assembly steps |

| Cost Efficiency | Can lower overall costs by integrating parts | Generally lower costs for high-volume production |

| Strength & Durability | Enhanced through metal inserts | Depends on plastic properties alone |

Conclusion

In conclusion, insert injection molding is a transformative manufacturing technique that offers numerous advantages in various industries. It empowers manufacturers to create stronger, more efficient, and innovative products while streamlining production processes. Whether you’re looking to enhance product functionality, reduce costs, or improve product design, insert molding is a valuable tool for achieving these goals.

If you’re interested in exploring the possibilities of insert molding or have inquiries about our services at Zhongde, we invite you to contact us. Our team of experts is ready to assist you in realizing the full potential of insert molding for your specific applications. Don’t hesitate to reach out and we can help you bring your projects to fruition.