Injection molding cooling systems play a crucial role in the injection molding process, directly influencing both product quality and production efficiency. The cooling stage accounts for about 60-70% of the injection molding cycle. Reducing cooling time and improving cooling efficiency will make injection molding production more efficient. To achieve this goal, two crucial elements are needed: the right injection mold cooling systems design and the ideal cooling method. In this post, we’ll delve into the critical role of injection molding cooling systems, guiding you in selecting the best options for your projects.

Injection Molding Machine Cooling Systems Methods

There are two standard methods for injection molding machine cooling systems: air cooling system and water cooling system.

Air Cooling System

Air-cooling systems function by using fans or blowers to dissipate heat from the mold’s surface. Unlike water-cooling systems, they rely on convection, where hot air is replaced by cooler air, gradually lowering the mold’s temperature.

Air cooling is a practical choice for molds with simpler designs and materials less sensitive to temperature fluctuations. While it offers cost-effective advantages and ease of installation, it falls short in terms of efficient heat absorption and precise temperature control when compared to water-cooled systems.

Water Cooling System

Water-cooling systems operate by circulating cold water through channels within the mold. This water absorbs heat from the mold, reducing the temperature of the plastic material. It works on the principle of conduction, where heat transfers from the hot mold to the cooler water. It is an ideal cooling system for intricate molds and materials sensitive to temperature changes.

Compared with an air cooling system, a water cooling system has exceptional heat absorption and temperature control, and it is an ideal cooling system for intricate molds and materials sensitive to temperature changes. However, it needs higher initial setup and maintenance costs compared to an air cooling system.

Please note: In cooling systems, the “water” used is actually a mix of fluids. The cooling tower blends water with a biocide to combat microbial growth. In the lines near the injection mold, water combines with ethylene glycol to prevent rust formation.

Two Options of Cooling in Injection Mold

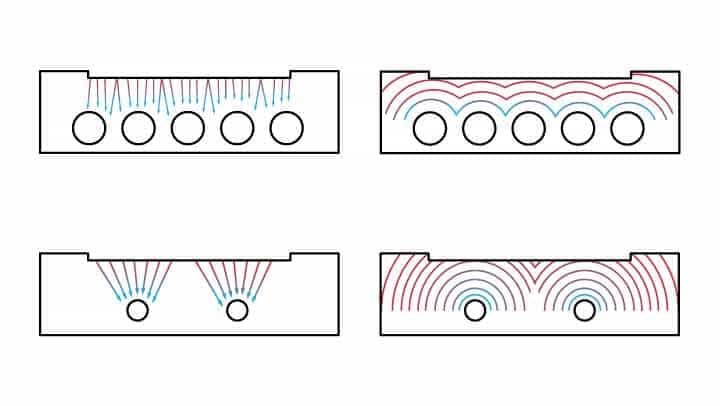

There are two primary types of cooling in injection mold — traditional cooling and conformal cooling. Each one is built on the general concept of cooling channels through which a cooling agent (such as coolant or water) can flow.

Traditional Cooling:

This method involves creating cooling channels in the mold tool through standard techniques like drilling or milling. These channels are typically straight but may include features like baffles or bubblers. Traditional cooling is most suitable for parts with simpler geometries, ensuring effective cooling throughout the entire part.

Conformal Cooling:

Conformal cooling revolutionizes injection molding, particularly for complex parts. It introduces cooling channels that closely match the intricate geometry of these parts. This approach ensures consistent cooling, even in challenging-to-reach areas of the mold.

The Main Components of Injection Molding Cooling Systems

In injection molding, regardless of the cooling channel type within the mold, there’s a risk of part defects when certain areas of the mold stay too hot and are far from the cooling channels. To address this challenge and create a more efficient cooling system around the molded part, designers employ specific features known as bafflers, bubblers, and thermal pins.

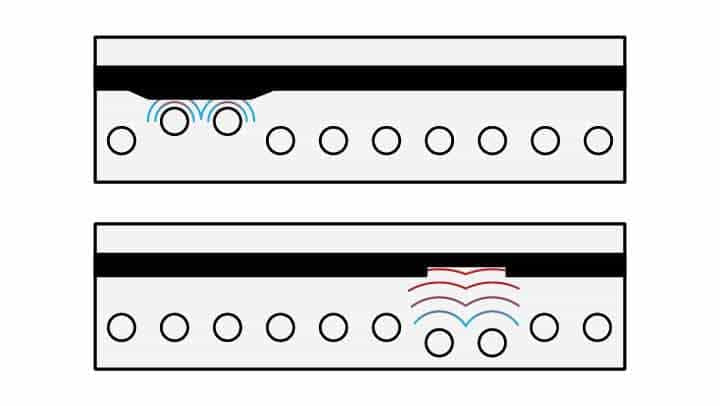

Baffles:

Baffles are blade-like metal plates within cooling channels. They divert coolant from a main channel to a side channel and back, creating a helix-like flow. This design enhances temperature distribution by increasing the surface area that coolant can reach. When dealing with laminar flows, bafflers introduce turbulence into the coolant’s path. Turbulence enhances heat dissipation by exposing more of the coolant’s surface to the hot injection mold.

Bubblers:

Bubblers are tubes inserted into drilled holes to connect coolant channels. They allow coolant to flow from one channel, bubble up through the tube, and then return to another channel. This mechanism increases surface exposure to coolant and is particularly useful for areas that lack milled or drilled channels. Bubblers play a crucial role, particularly when dealing with laminar flows, same as baffles, they introduce turbulence into the coolant’s path to enhance heat dissipation.

Thermal Pins:

Thermal pins are fluid-filled cylinders placed in cooling channels. They draw heat away from the mold by cycling between gas and liquid phases. As the gas cools, it condenses into a liquid, repeating the process. Thermal pins are highly effective at heat conduction, provided there are no air gaps between the pin and the mold.

Cooling-Related Defects in Injection Molding

A well-designed injection molding cooling systems can significantly shorten molding time, improve injection molding productivity, and reduce costs. However, an improperly designed cooling system will lengthen the molding time and increase costs; uneven cooling will further cause various defects of plastic products. Here are some common cooling-related defects in injection molding:

Warping:

Warping occurs when the part cools unevenly, causing it to deform or bend. This defect is often seen in parts with varying wall thicknesses or inadequate cooling channels.

Sink Marks:

Sink marks are depressions or dimples on the surface of the molded part. They are caused by uneven cooling, where thicker sections of the part cool more slowly than thinner sections, resulting in the surface sinking inwards.

Blisters:

Blisters are raised or bubble-like defects on the surface of the part. They occur when air or gas is trapped within the material due to insufficient cooling, causing it to expand and form blisters.

Jetting:

Jetting happens when the material flows too quickly into the mold, causing it to cool rapidly upon contact with the mold surface. This can result in visible streaks or lines on the part’s surface.

To prevent these cooling-related defects, it’s crucial to design and implement an effective injection molding cooling system, optimize cooling channel placement, and monitor and control cooling parameters during the injection molding process.

7 Plastic Injection Molding Defects: Their Causes and Solutions

Injection Molding Cooling Systems Design Principles

In order to improve productivity and ensure product quality, the basic principle of injection molding cooling systems design is to ensure uniform cooling of plastic parts. Please pay attention to the following points when designing:

The More Cooling Water Holes, The Better

Use as many cooling water holes as possible and as large as possible to make the cavity surface temperature uniform.

Appropriate Distance Between Cooling Water Hole and Cavity Surface

The distance between the hole wall and the mold cavity should be appropriate, generally greater than 10mm, and 12~15mm is commonly used. When the wall thickness of the plastic part is uneven, the cooling water channel in the thick wall should be appropriately close to the mold cavity.

Enhance Cooling at the Gate

During molding, the high-temperature plastic melt is filled into the cavity through the gate. The mold temperature is high near the gate and the temperature at the end of the material flow is low. Set the cooling water inlet near the gate so that the overall flow direction of the cooling water and the material flow direction in the cavity tend to be the same (the water and materials are parallel), and the cooling is relatively uniform.

Reasonably Arrange the Location of Cooling Water Holes

Reasonably set the arrangement of cooling water channels to reduce the temperature difference between inlet and outlet water. The arrangement of cooling water holes must be reasonable. The cooling water channel should be arranged according to the shape of the mold cavity as much as possible. The shape of the plastic part is different, and the position of the cooling water channel is also different.

water holes location based on shape

Conclusion

The injection molding cooling systems is a vital aspect of the manufacturing process, impacting product quality and efficiency. Understanding the methods and designs for effective injection molding cooling systems is essential for successful mold design. At Zhongde, we offer extensive expertise in cooling methods and mold design techniques. Our experienced team is ready to collaborate with you to optimize your injection molding projects for production efficiency and quality. Whether you’re seeking advice on technology options, materials, or project development, we’re here to assist you.