How to Prevent and Eliminate Gas Marks in Plastic Injection Molding?

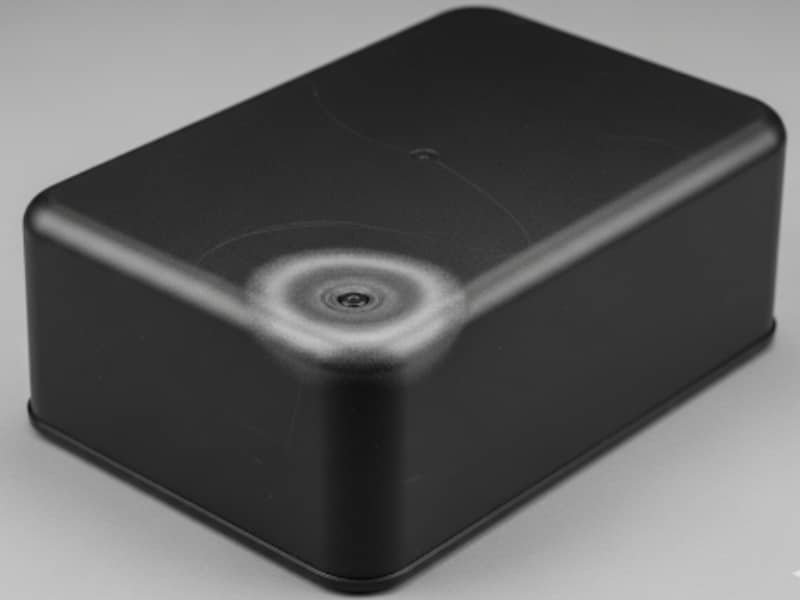

Gas mark in injection molding is a common and challenging defect in the injection molding process. Understanding what gas marks are, their negative effects, causes, and how to avoid them is important to achieve high-quality injection molding parts. What Is Gas Mark in Injection Molding? Gas mark in injection molding refers to surface defects that […]

How to Prevent and Eliminate Gas Marks in Plastic Injection Molding? Read More »