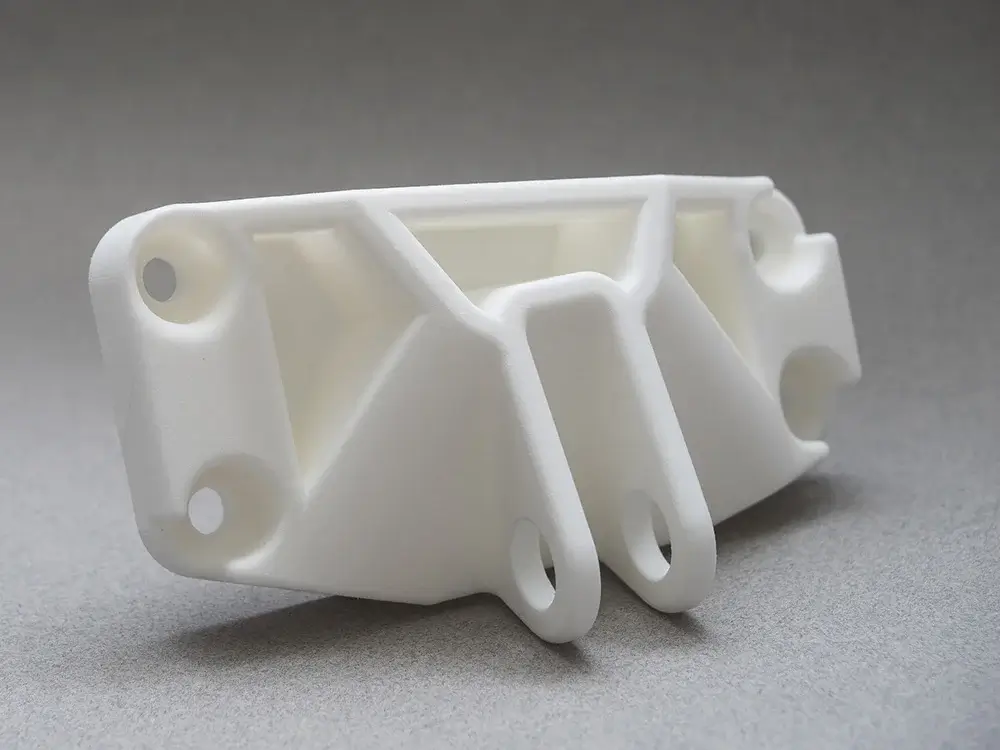

Custom 3D Printing Parts

- Rapid prototype

- Higher quality and lower cost

- Create almost any shape of 3D scale model parts

- All uploads are secure and confidential!

Home » Custom Products » 3D Printing Parts

Zhongde has introduced much-advanced equipment for 3D printing, which can be used to print plastic & metal mechanical parts and components, realize one-time printing, and reduce production costs. For 3D printing parts, we provide customization of personalized graphics in multiple fields according to customers’ requirements. As a manufacturer of plastic & metal 3D printed industrial parts, Zhongde Molding consistently updates equipment for casting and painting of 3D FDM/SLS printed parts.

Types of 3D Printing Parts

Specification of 3D Printing Parts

| Name | Description |

|---|---|

| Maximum Size | 1500x1500x1000mm |

| Color | White, Black, Transparent, or according to Pantone No. |

| Tolerance | ±0.05mm |

| Surface Finishing | Glossy, Semi-gloss, Matte, Textured finish, As-machined |

| Addictives | UV absorbers, Flame retardants, Plasticizers, Colorants, Carbon fibers, Glass fibers |

| Logo | Debossed, Embossed, Printing |

| Drawing Format | 2D Drawing: PDF/JPG/PNG. 3D Drawing: STEP/STP/IGS/DXF/DWG |

| Product Volume | 50,000,000 Pcs/Month |

Available Material of Painting 3D Printed Parts

Stainless Steel

The brightness of stainless steel is close to the mirror surface. and it has excellent corrosion resistance form ability. compatibility and toughness.

Aluminum

Aluminum is a lightweight, corrosion-resistant metal known for its versatility and wide range of industrial applications.

VMQ

Silicone also named VMQ, it has excellent electrical insulation and high stability to thermal oxidation and ozone. inertia. The mechanical strength is low.

PA

Nylon polyamide (PA) is a high-performance thermoplastic, which have excellent mechanical properties, thermal, chemical, and abrasion resistant.

PP

Polypropylene (PP) is a commodity plastic with low density and high heat resistance. Excellent chemical resistance and food-safe grades.

ABS

Good strength structural stability and excellent thermal, corrosion, and abrasion resistance. ABS is a common low-cost plastic injection molding material.

It is easy to fill the form.

Better Quality, Faster Delivery

From design to final parts, from rapid prototyping to mass production, Zhongde's one-stop service meets your needs.

Upload your design drawing and all uploads are secure and confidential!

Upload your design drawing and all uploads are secure and confidential!