Silicone rubber molding is a versatile and widely used manufacturing process that enables the production of durable, flexible, and heat-resistant components across numerous industries. This article provides a comprehensive overview of silicone rubber molding, including the material properties, types of silicone rubber, and the main molding processes—compression molding, transfer molding (also called rotary molding), and injection molding. We will also explore the specific workflows and advantages of each process, along with common applications of molded silicone parts.

What Is Silicone Rubber Molding?

Silicone rubber molding is a manufacturing technique that involves shaping silicone rubber material into desired parts using heated molds. The process typically applies heat and pressure to cure or vulcanize the silicone, transforming it from a raw or liquid state into a solid, elastic product that retains the mold’s shape. Silicone rubber itself is prized for its unique combination of properties: it is highly flexible, resistant to extreme temperatures (both high and low), chemically inert, biocompatible, and environmentally stable. These attributes make silicone rubber part ideal for applications ranging from medical devices to automotive components and consumer electronics.

Silicone Rubber Types

Silicone rubber materials used in types of rubber molding are generally classified into three main types according to their processing method:

High Temperature Vulcanizing (HTV) Silicone: Also known as High Consistency Rubber (HCR), HTV is a high-viscosity, gum-like elastomer with molecular weights of 400,000–800,000. Requiring heat (150–170°C) and catalysts (peroxide or platinum) for curing, HTV offers exceptional mechanical strength, making it ideal for robust parts like automotive gaskets or industrial seals.

Room Temperature Vulcanizing (RTV) Silicone: RTV silicone cures at room temperature (20–25°C), often used in liquid or paste form. With lower viscosity and hardness (15–40 Shore A), it’s perfect for prototyping, small-scale moulds, or sealants in electronics and aerospace.

Liquid Silicone Rubber (LSR): A low-viscosity, two-part platinum-cured elastomer, LSR flows effortlessly into complex moulds, curing rapidly at 120–180°C. Its biocompatibility and precision make it the material of choice for high-volume production of medical devices, baby products, and intricate electronics components.

3 Silicone Rubber Molding Processes

Compression Molding Process

Compression molding, a foundational silicone moulding process, excels in crafting simple, large-scale moulded silicone parts with cost-effective simplicity. It involves placing a pre-measured amount of solid or pre-vulcanized silicone rubber into an open, heated mold cavity. The mold is then closed, and pressure is applied to force the material to fill the mold completely. Heat initiates the curing (vulcanization) of the silicone, solidifying it into the desired shape. This technique widely used for HTV silicone.

This silicone rubber molding process shines for low to medium production runs, producing parts like gaskets, seals, or automotive panels. Relatively low tooling costs and simplicity, making it ideal for large, less complex designs. However, surface finish inconsistencies may necessitate post-processing, and cycle times are longer compared to other methods.

Transfer Molding Process

Transfer molding, sometimes referred to as rotary molding, is a variation of compression molding designed to improve material flow and part complexity. In this process, silicone rubber is first heated and softened in a chamber outside the mold. Then, it is transferred under pressure into a closed mold cavity through a runner system. It ideal for intricate moulded silicone components.

This silicone molding process excels for small to medium production runs, producing high-strength parts like electrical connectors, seals, or medical components. It’s faster cycle times than compression molding and the ability to handle intricate designs with minimal voids. However, it generates more material waste due to sprues and runners, and tooling costs are higher than compression molding.

Injection Molding Process

Injection molding is the most advanced and widely used silicone molding process, especially for high-volume production. It is particularly effective when using liquid silicone rubber (LSR) but can also be applied to HTV silicone with specialized equipment.

HTV Injection Molding

1. First, feeding pre-mixed HTV silicone, blended with peroxide catalysts, into a heated barrel (150–170°C).

2. A reciprocating screw, housed within the injection unit, melts the high-viscosity silicone and injects it through a nozzle into a closed, heated mould (150–170°C) at pressures of 5–10 MPa.

3. The material fills the cavity, curing over 10–30 minutes as heat triggers crosslinking.

4. Post-curing in an oven (200–250°C for 24 hours) removes volatile peroxide byproducts, such as acid powders known as “blooming,” ensuring part purity.

5. The mould opens, and the part is ejected, often requiring manual deflashing to remove flash.

This silicone moulding process suits robust parts like automotive gaskets or industrial seals, offering high strength but longer cycle times and higher labour costs due to post-processing.

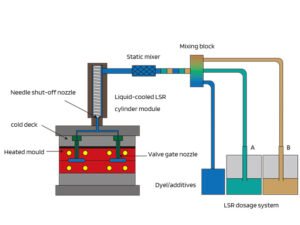

LSR Injection Molding

1. LSR, a two-part platinum-cured liquid, is stored in drums (20–200 liters) and pumped in a 1:1 ratio through a static mixer into a cooled barrel to prevent premature curing.

2. The low-viscosity LSR is injected into a heated mould (120–180°C) at lower pressures (<1000 PSI), filling intricate cavities in seconds.

3. Curing occurs rapidly (30–60 seconds) due to platinum catalysis, producing flash-free parts with smooth finishes.

4. The mould opens, and parts are ejected automatically, requiring no post-curing.

This silicone molding process is ideal for high-volume, precision parts like medical catheters, baby nipples, or electronics seals, offering repeatability, minimal waste, and biocompatibility.

Common Silicone Rubber Molded Parts

The silicone rubber molding process produces a diverse array of moulded silicone components without rubber molding defects, leveraging silicone’s flexibility, heat resistance, and biocompatibility. These parts, crafted through compression, transfer, or injection molding including but not limited to:

Medical Devices: LSR injection molding creates biocompatible components like catheters, syringe seals, respiratory masks, and dental implants.

Automotive Components: HTV compression and injection molding produce durable gaskets, O-rings, spark plug boots, and hose seals.

Consumer Goods: LSR-moulded items, such as baby bottle nipples, kitchenware (e.g., baking moulds, spatulas), and wearable bands.

Electronics: RTV and LSR molding craft keypads, cable seals, and connectors.

Industrial Seals and Gaskets: Compression-moulded HTV components, including pump seals, valve gaskets, and aerospace hoses.

Partner with a Trusted Silicone Molding Expert – Zhongde

Looking for a reliable silicone molding supplier? Zhongde offers expert solutions with precision tooling, high-quality materials, and custom support from design to delivery. Partner with us to bring your silicone components to life with confidence and efficiency.