Surface Finishing Service

- All uploads are secure and confidential!

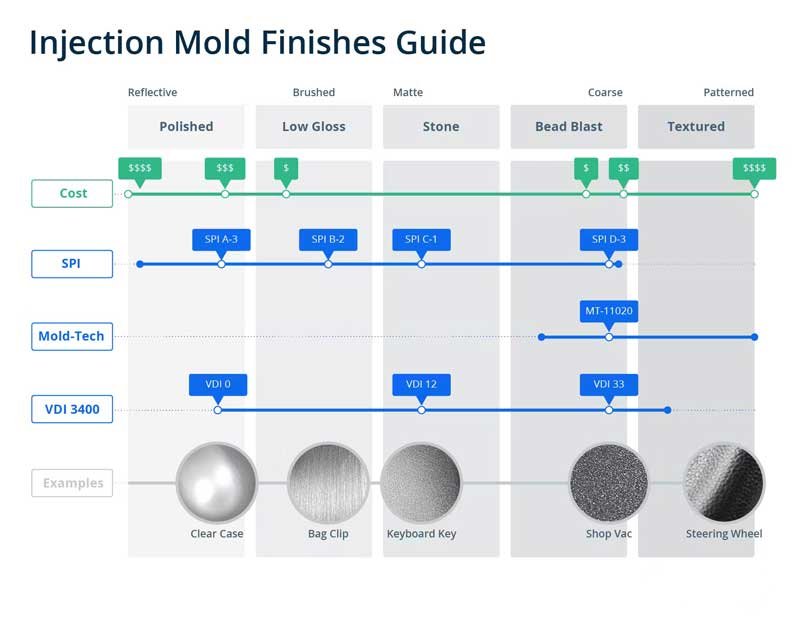

Injection Mold Surface Finishing Standerds

Zhongde has access to a diverse marketplace of molding suppliers and all standard mold surface finishing options. Mold finishes can range from glossy to matte to even patterned. Finishes applied to the surface of the mold cavity transfer to the surface of the molded part. For example, a mold surface that is polished to be reflective will make a reflective (or transparent) part. Mold finishes differ from CNC machined or 3D printed parts, where each component is treated individually. Adding a finish or texture can change the tool’s price depending on the process required, but it does not alter the price of the individual parts.

Our standard mold finishing includes the following:

- Society of Plastics Industry (SPI) Mold Finishes

- VDI

SPI Finishes vs VDI Finishes

SPI Surface Finishing Standard

SPI Finish (SPI Finishes) is also known as “SPI Mold Finish (SPI Mold Finishes)” or “SPI Surface Finishes“.

The SPI Surface Finishing refers to the American surface finishing standard set by SPI (Society of the Plastics Industry).

SPI A Finishes

SPI A-1

Diamond buffed with grade #3, 6000 grit for a highly polished finish. Also suitable for producing optically clear parts. Has an average surface roughness of 0.012-0.025µm Ra.

SPI A-2

Diamond buffed with grade #6, 3000 grit for a high polish finish. Also suitable for producing transparent parts. Has an average surface roughness of 0.025-0.050µm Ra.

SPI A-3

Diamond buffed with grade #15, 1200 grit for a high-to-medium polished finish. Also suitable for producing non-optical transparent parts. Has an average surface roughness of 0.050-0.100µm Ra.

SPI B Finishes

SPI B-1

A 600-grit sanded finish for a medium polish with a surface roughness of 0.05-0.10µm Ra.

SPI B-2

A 400-grit sanded finish for a medium polish with a surface roughness of 0.10-0.15µm Ra.

SPI B-3

A 320-grit sanded finish for a medium-to-low polish with a surface roughness of 0.28-0.32µm Ra.

SPI C Finishes

SPI C-1

A 600 stone finish for a low polish with a surface roughness of 0.35-.40µm Ra.

SPI C-2

A 400 stone finish for a low polish with a surface roughness of 0.45-.55µm Ra.

SPI C-3

A 320 stone finish for a low polish with a surface roughness of 0.63-.70µm Ra.

SPI D Finishes

SPI D-1

Dry blasted with glass bead for a satin finish with a surface roughness of 0.80-1.00µm Ra.

SPI D-2

Dry blasted with #240 oxide for a dull finish with a surface roughness of 1.00-2.80µm Ra.

SPI D-3

Dry blasted with #24 oxide for a dull finish with a surface roughness of 3.20-18.00µm Ra.

VDI Surface Finishing Standard

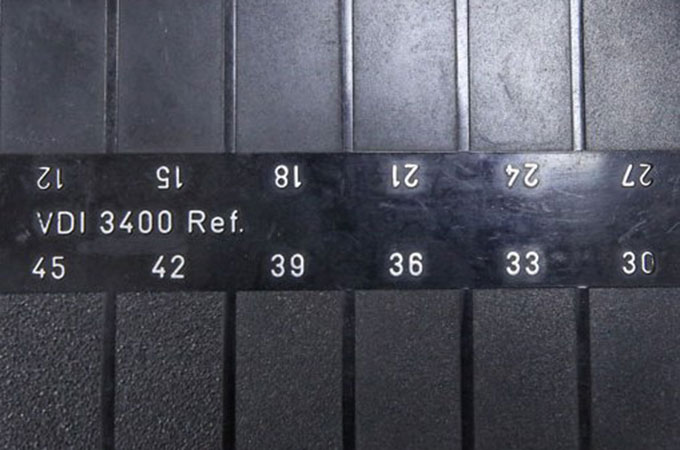

VDI (EMD) Finishes

VDI 12

A 600 stone low-polish finish with an average surface roughness of 0.40µm Ra.

VDI 15

A 400 stone low-polish finish with an average surface roughness of 0.56µm Ra.

VDI 18

A glass bead blast satin finish with an average surface roughness of 0.80µm Ra.

VDI 21

A #240 oxide dry blast dull finish with an average surface roughness of 1.12µm Ra.

VDI 24

A #240 oxide dry blast dull finish with an average surface roughness of 1.60µm Ra.

VDI 27

A #240 oxide dry blast dull finish with an average surface roughness of 2.24µm Ra.

VDI 30

A #24 oxide dry blast dull finish with an average surface roughness of 3.15µm Ra.

VDI 33

A #24 oxide dry blast dull finish with an average surface roughness of 4.50µm Ra.

VDI 36

A #24 oxide dry blast dull finish with an average surface roughness of 6.30µm Ra.

VDI 39

A #24 oxide dry blast dull finish with an average surface roughness of 9.00µm Ra.

VDI 42

A #24 oxide dry blast dull finish with an average surface roughness of 12.50µm Ra.

VDI 45

A #24 oxide dry blast dull finish with an average surface roughness of 18.00µm Ra.

Secondary Surface Finishing

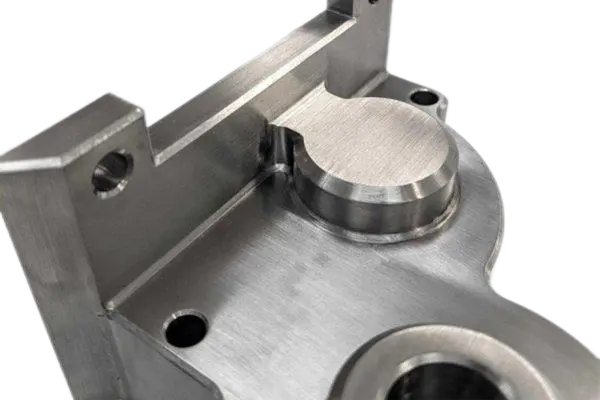

As Machined

Smoothing

Material Compatibility: All plastic as and metals

Bead Blasting

Material compatibility: All metals Color: Uniform matte of raw material color

Powder Coating

Material compatibility: All metals Color: Black or any RAL code or Pantone number.

Anodizing Color (Type II)

Material compatibility: Aluminum alloys Color: Black, clear or any RAL code or Pantone number

Anodizing Hardcoat (Type III)

Material compatibility: Aluminum alloys Color: Black or clear

Electropolishing

Material compatibility: All metals Color: Natural metal color

Black Oxide

Material compatibility: Stainless steel and copper alloys Color: Black

Chromate Conversion Coating (Alodine/Chemfilm)

Material compatibility: Aluminum and copper alloys Color: Clear or yellow

Brushing

Material compatibility: All metals

Knowledge Hubs

Understanding Precision Injection Molding: A Comprehensive Guide

Precision injection molding is a fundamental process in modern manufacturing, known for creating accurate and intricate parts and components. Its

Deal with Warpage in Injection Molding: Causes and Prevention

Plastic injection molding is a widely used manufacturing process, but it’s not immune to defects. One such issue that manufacturers

How Much Do You Know About Precision Molding of Plastic Parts?

1. Typical precision molding of plastic parts: 1) The high processing precision of the plastic parts itself; 2) Typical micro