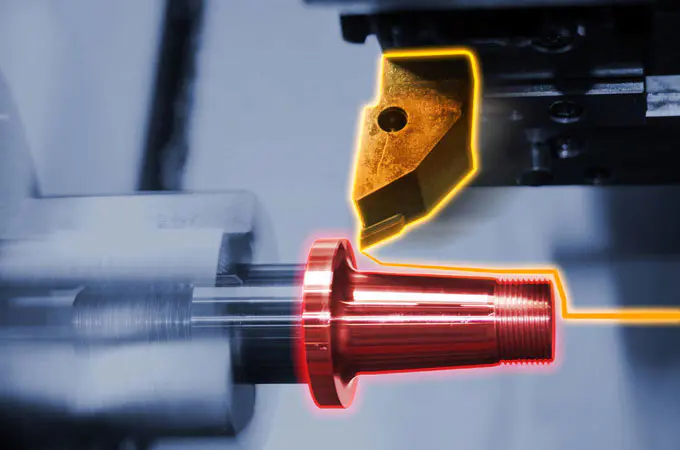

CNC Turning Serivce

- We Offer custom CNC turning service for your on-demand parts.

- Get an online quote with a competitive price for high-quality turned parts.

- All uploads are secure and confidential

Zhongde CNC Turning Service

Size of CNC Turning Machined Parts

The below table shows the regular size of the custom CNC milling machined parts. If you need a unique size product design, Zhongde, as a professional China precision CNC machining manufacturer, will help you achieve it at a competitive price.

| Size | Metric | Inch |

|---|---|---|

| Length | 2500 | 98.4 |

| Width | 2000 | 78.7 |

| Height | 1500 | 59 |

Available Material of CNC Turning

Choosing the exact materials is an important step in the manufacturing of your CNC machining projects. At Zhongde, a professional on-demand manufacturer, we offer a wide range of CNC machining materials to meet diverse project requirements. Our materials selection includes high-quality metals and various plastics. With our extensive material expertise and focus on quality, we ensure that your CNC-machined parts are manufactured to the highest standards and meet your specific needs.

CNC Metals

Aluminum

Copper

Stainless Steel

Brass

Carbon Steel

Steel Alloy

CNC Plastics

ABS

Nylon 6

PVC

HDPE

PC | Polycarbonate

PP | Polypropylene

POM | Delrin

LDPE

UHMWPE

PTFE

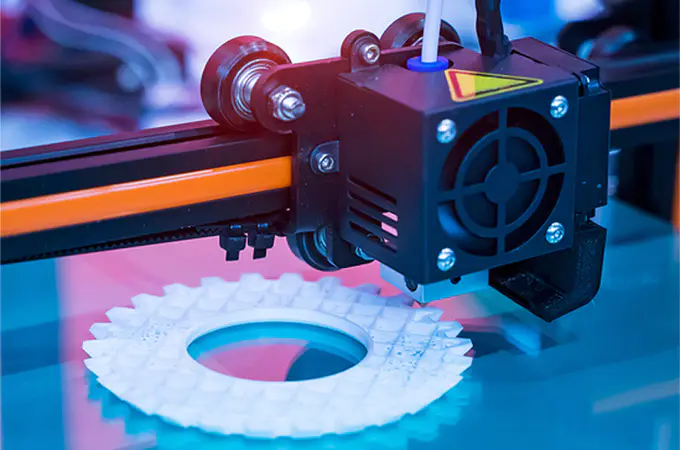

Custom Products

Service

CNC Milling Surface Finishing

| Finishing | Description | Material Compatibility | Color | Link | |

|---|---|---|---|---|---|

|

As Machined | For as machined all sharp edges are removed and parts are deburred. Tool marks are visible. | All plastics and metals | Uniform of raw material color | Learn More |

|

Smoothing | A finishing CNC machining operation can be applied to the part to reduce its surface roughness. Machine marks are less evident but still visible. | All plastics and metals | Uniform matte of raw material color | Learn More |

|

Bead Blasting | Bead blasting adds a uniform matte or satin surface finish on a machined part, removing the tool marks. | All metals | Uniform matte of raw material color | Learn More |

|

Powder Coating | Powder coating compatible with all metal materials and can be combined with a bead blasting to create parts with smooth and uniform surfaces and excellent corrosion resistance. | All metals | Black or any RAL or Pantone code | Learn More |

|

Black Oxide | Black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection. | Stainless steel and copper alloys | Black | Learn More |

|

Electropolishing | An electrochemical process used to polish, passivate and deburr metal parts. It is useful to reduce surface roughness. | All metals | Natural metal color | Learn More |

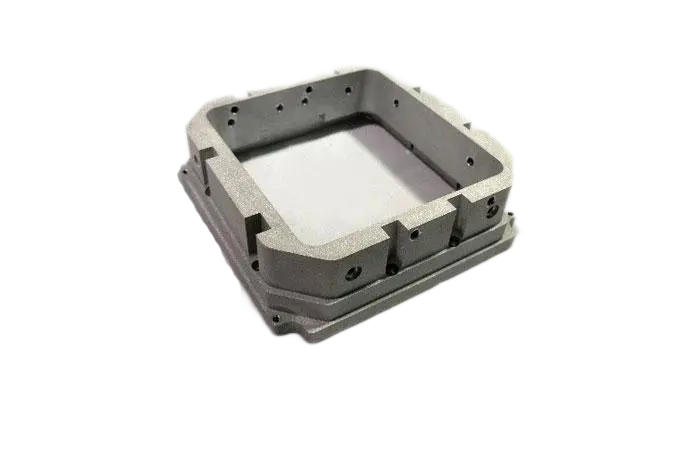

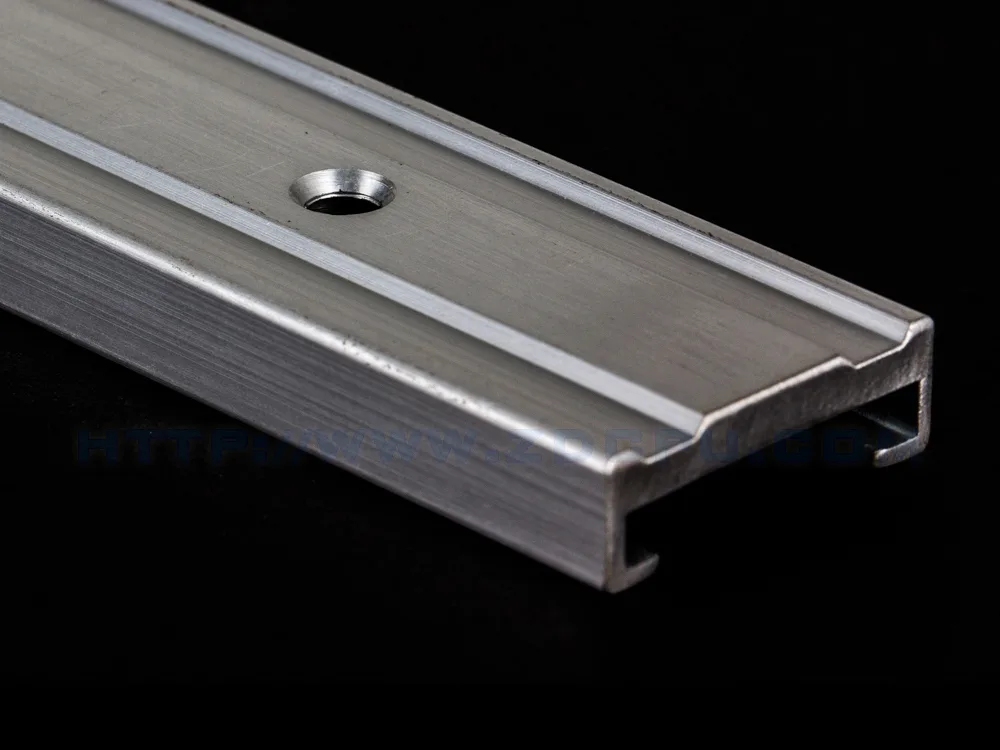

Related Products Of CNC Machining

Knowledge Hubs

What Technological Conditions Need to Be Met for Injection Mold Tooling Steel?

Generally, the manufacturing of injection mold tooling cannot avoid multiple machining processes such as forging, cutting, and heat treatment. In

A Comprehensive Guide to the Types of Springs and Applications

Do you know there are many different types of springs? Springs, those unassuming yet indispensable devices quietly enable a multitude

Common Quality Defects of Plastic Injection Parts

After injection molding, some problems come into being which will affect the assembly efficiency or the performance of the whole