What is Water Assisted Injection Molding process?

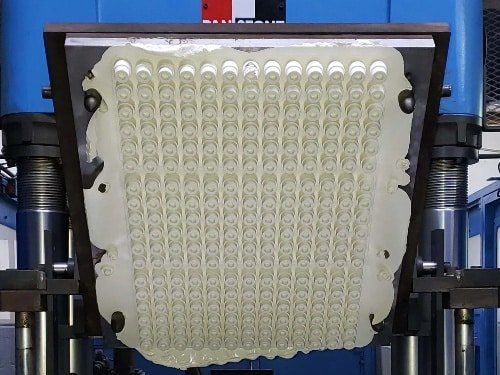

The water assisted injection molding process, one of injection molding types, builds on traditional injection molding by using water pressure to displace material and form internal cavities. It addresses challenges in thick-walled components. The water assisted injection molding technique is widely used for lightweight , hollow, and structurally stable plastic components. What is Water Assisted […]

What is Water Assisted Injection Molding process? Read More »