Turkish customers save time and labor costs by outsourcing parts production and assembly services.

Turkey’s customer Veysel Yilmaz is engaged in the R&D and production of beauty equipment. The competition for beauty equipment is very fierce in the local market. A high-quality and inexpensive product will help customers improve their competitiveness. The replacement of beauty equipment is also very fast. From the overall configuration to the appearance design, customers develop new models almost every year, and this year is no exception. Due to the need of business expansion, the production of new products needs to be mass-produced to improve efficiency and enable products to be put on the market as soon as possible. The customer’s own factory produces the core components and instrument body.

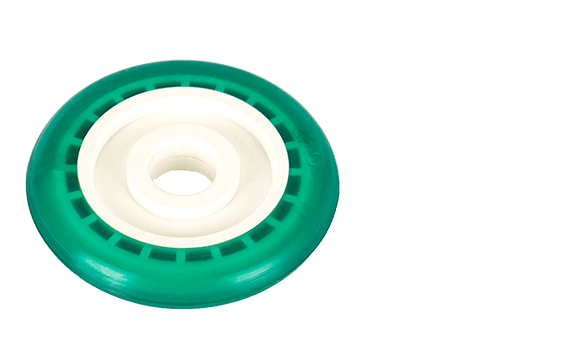

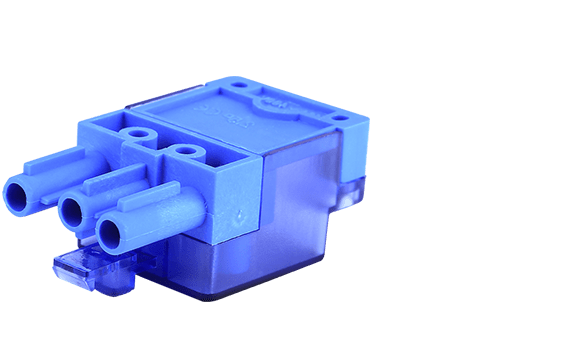

The production of the handle needs to be outsourced to a strong factory. After many investigations and comparisons, the customer found that we are not only experienced, but also have many similar cooperative customers in the European market. What’s more, we can not only produce various high-precision cnc machining plastic parts, but also provide parts assembly services at reasonable prices and good service. It is worth mentioning that our assembly parts are also of good quality。 Finally, we reached close cooperation. The customer sent us the wires and electronic components inside the handle. We produced the handle shell, switch button, and connector, and finally assembled the finished product, which can be directly connected to the machine. After rigorous testing, all the spare parts we produce are qualified. Customers have shortened the production cycle to a large extent, saved time and labor costs, and thus we have reached a long-term cooperative relationship.