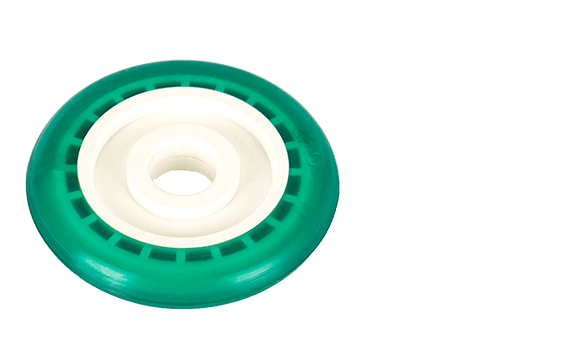

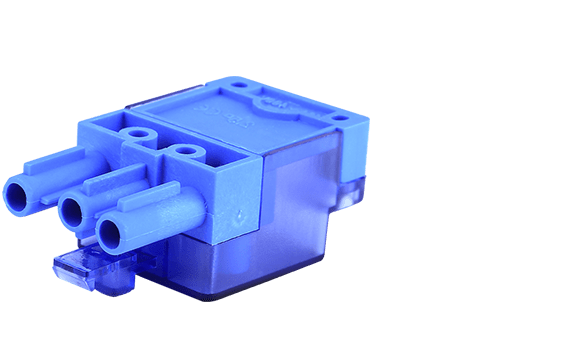

Injection Molding Process for Enhancing Dustproof Covers for Agricultural Harvesters

Industry: Agriculture machinery

Technology: Injection Molding,

Introduction:

As an on-demand manufacturer, we were presented with a unique challenge by one of our clients in the agricultural machinery industry. The client sought to improve the quality of their dustproof covers for harvesters, with a focus on enhancing power transfer efficiency, extending service life, and ensuring versatility. This case study highlights our collaborative efforts and innovative solutions in addressing these specific challenges, resulting in superior dustproof covers for agricultural harvesters.

Challenge from Client:

The client approached us to take on the challenge of improving their dustproof covers. They sought a partner who could provide expertise in design optimization, material selection, and manufacturing processes to achieve their goals. The primary focus was on enhancing power transfer efficiency, extending service life, and ensuring versatility for agricultural harvesters.

Collaborative Approach:

We established a close collaboration with the client’s engineering team to fully understand their requirements, performance expectations, and specific operating conditions for the dustproof covers. This collaborative approach allowed us to work towards developing tailored solutions that aligned with the client’s objectives.

To address the challenges associated with the client’s dustproof covers, we implemented the following solutions:

- Design Optimization: Through comprehensive analysis and simulations, we optimized the design of the dustproof covers. This included improving the sealing mechanisms, ensuring proper fit and alignment, and enhancing airflow management. The optimized design resulted in improved power transfer efficiency, reduced dust ingress, and enhanced overall performance.

- Material Selection: The material should be highly durable to withstand the harsh operating conditions of agricultural harvesters, including exposure to dust, moisture, and mechanical stress. And the material should have excellent resistance to dust ingress, water, UV radiation, and temperature fluctuations, ensuring long-term protection and performance. the material should be able to withstand impacts and vibrations without compromising its integrity. The material should be resistant to common agricultural chemicals, such as fertilizers and pesticides. Based on these requirements, one suitable material choice could be thermoplastic elastomers (TPE).

- Manufacturing Techniques: Our expertise in manufacturing processes enabled us to efficiently produce enhanced dustproof covers. We utilized advanced techniques of injection molding to ensure precise and consistent part production. Additionally, we employed rigorous quality control measures throughout the manufacturing process to ensure the highest level of product quality and performance.

Results and Benefits:

Our collaborative efforts with the client resulted in significant improvements in the dustproof covers for agricultural harvesters, yielding the following results and benefits:

- Enhanced Power Transfer Efficiency: The optimized design of the dustproof covers minimized energy losses and improved power transfer efficiency. This led to increased overall productivity and performance of the agricultural harvesters, contributing to improved operational efficiency for the client.

- Extended Service Life: By selecting high-quality materials and implementing robust manufacturing processes, the dustproof covers exhibited exceptional durability. The extended service life of the covers reduced maintenance and replacement costs for the client, resulting in enhanced cost-effectiveness.

- Versatility in Different Operating Conditions: The redesigned dustproof covers demonstrated enhanced versatility, capable of withstanding a wide range of operating conditions. This flexibility allowed the agricultural harvesters to perform optimally across various environments, ensuring consistent productivity and minimizing downtime.

Conclusion:

Through our collaboration with the client, we successfully addressed the challenges associated with their dustproof covers for agricultural harvesters. By optimizing the design, selecting suitable materials, and employing efficient manufacturing techniques, we enhanced power transfer efficiency, extended service life, and ensured versatility. This case study showcases the value of our on-demand manufacturing services in delivering tailored solutions to meet the specific needs of our clients in the agricultural machinery industry. The improved dustproof covers provided our client with a competitive advantage, leading to increased customer satisfaction, improved operational efficiency, and long-term business success.

Start A New Project With Zhongde Now!

- All information and uploads are secure and confidential