Enhancing Blood Glucose Meter Housing by Injection Molding Process

Industry: Medical Equipment

Technology: Injection Molding,

Introduction:

In the competitive market of medical devices, our client, a leading manufacturer of blood glucose meters, approached us with a challenge. They sought to improve their blood glucose meter housing to enhance functionality, durability, and regulatory compliance. Through our expertise in on-demand manufacturing, we embarked on a collaborative journey to meet their requirements and deliver an exceptional solution.

Challenge from Client:

Our client aimed to upgrade their blood glucose meter housing, seeking improved functionality, longevity, and adherence to regulatory standards. They sought a partner who could provide design optimization, material expertise, and efficient manufacturing processes to achieve their goals.

To address the challenge of enhancing the blood glucose meter housing, we implemented the following solutions:

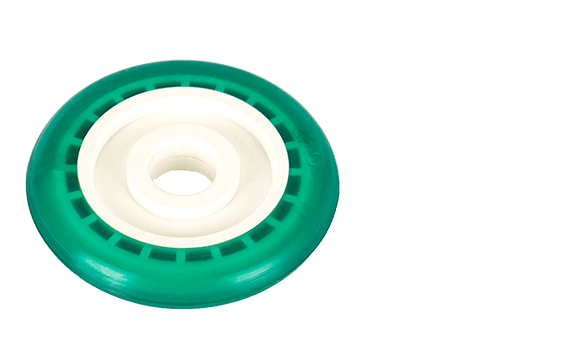

- Material Selection: After careful evaluation, we recommended medical-grade thermoplastics acrylonitrile butadiene styrene (ABS). The material offered excellent impact resistance, chemical resistance, and dimensional stability, meeting the client’s requirements for durability and regulatory compliance.

- Design Optimization: Our team conducted a thorough analysis of the existing housing design, focusing on user ergonomics and intuitive functionality. By incorporating user-centric improvements, the design enhanced grip, and improved display visibility, we ensured an enhanced user experience.

- Manufacturing Process: Leveraging the efficiency and precision of injection molding, we manufactured the blood glucose meter housings. Injection molding allowed us to produce complex parts with precise dimensions, ensuring consistency, scalability, and cost-effectiveness.

Results and Benefits:

Through our collaborative approach and innovative solutions, we achieved the following results and benefits for our client:

- Enhanced Functionality: The optimized housing design improved user ergonomics, ensuring a comfortable grip and intuitive operation. The incorporation of user-centric features and improved display visibility enhanced the functionality of the blood glucose meters.

- Increased Durability: By utilizing medical-grade thermoplastics, the housing gained exceptional durability, withstanding daily use, impacts, and exposure to chemicals. This extended the product’s service life and reduced the need for frequent replacements.

- Regulatory Compliance: Our collaboration ensured that the redesigned housing met stringent regulatory standards for biocompatibility and electrical safety. This allowed the client to confidently market their blood glucose meters while adhering to regulatory requirements.

Conclusion:

Through our collaborative partnership, we successfully enhanced the blood glucose meter housing, meeting the client’s requirements for functionality, durability, and regulatory compliance. By leveraging design optimization, material expertise, and efficient manufacturing processes, we delivered an exceptional solution. Our client gained a competitive edge with blood glucose meters that offered enhanced functionality, durability, and compliance, resulting in increased customer satisfaction and market success.

As an on-demand manufacturer, Zhongde is committed to providing tailored solutions to meet our client’s specific needs, ensuring the highest quality products in the medical device industry.