Injection mold polishing is the crucial final step in creating high-quality plastic parts. This essential technique refines the mold surface, directly impacting the finished component’s performance, aesthetics, and overall quality. In this article, we’ll explore the importance of mold polishing and the different methods used to achieve superior results in the injection molding service.

What is Plastic Injection Mold Polishing?

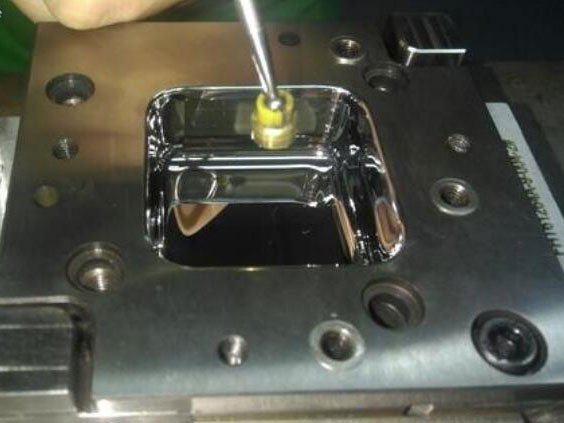

Injection mould polishing refers to the process of refining and smoothing the surfaces of the mold cavity and core used in injection molding. It involves the removal of imperfections, such as tool marks, scratches, and rough textures, to achieve a high-quality and mirror-like finish on the mold surfaces. The goal of mold polishing is to ensure that the molds produce parts with precise dimensions, excellent surface quality, and minimal defects. The mold polishing process typically involves using a series of abrasive materials, such as sandpaper, polishing compounds, and buffing wheels, along with various techniques and equipment. Skilled technicians carefully work on the mold surfaces, gradually removing imperfections and achieving the desired level of smoothness and shine.Why Should We Do Plastic Mold Polishing?

Mold polishing plays a crucial role in the injection molding process due to its numerous benefits and contributions to part quality and performance.Improved Part Quality

Mold polishing significantly enhances the surface finish of the mold cavity and core, which translates to superior part quality. The smooth and polished mold surfaces help achieve precise and consistent part dimensions, minimizing variations and ensuring the accurate reproduction of intricate details.Reduced Defects

Proper mold polishing helps minimize defects in the injection-molded parts. By eliminating surface imperfections, such as tool marks, scratches, or rough textures, mold polishing reduces the occurrence of defects like flow lines, sink marks, and part sticking. The smoother mold surfaces allow for better resin flow and cooling, reducing the risk of filling inconsistencies and promoting uniform part properties.Enhanced Appearance

Mold polishing significantly enhances the visual appeal of the injection-molded parts. The mirror-like finish achieved through polishing gives the parts a professional and premium look.Consistent Part Dimensions

Mold polishing contributes to achieving consistent part dimensions and improved dimensional accuracy. The removal of imperfections and the creation of smooth mold surfaces help maintain uniform resin flow and cooling during the injection molding process. This minimizes variations in part dimensions and ensures that each molded part meets the required specifications and tolerances.What are The Types of Mould Polishing Methods?

There are several mould polishing methods for achieving a polished finish in injection molding, and each one demands a high level of precision for the polishing process, smoothness, and geometric accuracy.Mechanical Mold Polishing

This method involves the use of mechanical tools, such as abrasive stones, sandpaper, polishing compounds, and buffing wheels, to manually polish the mold surfaces. It requires skilled operators who carefully remove imperfections and achieve the desired smoothness and finish.Chemical Mold Polishing:

Chemical polishing involves the use of chemical agents or solutions to dissolve a thin layer of the mold surface, resulting in a smoother finish. The chemicals used can vary depending on the type of mold material. This method is effective for achieving a high level of surface smoothness and can be combined with mechanical polishing for optimal results.Electrolytic Mold Polishing:

Electrolytic polishing uses an electrochemical process to remove surface imperfections. The mold is immersed in an electrolyte solution, and an electric current is applied to selectively dissolve the high spots and rough areas. This method is suitable for complex mold shapes and provides precise control over the polishing process.Ultrasonic Mold Polishing

Ultrasonic polishing utilizes high-frequency vibrations combined with abrasive particles to remove surface imperfections. It is particularly effective for polishing intricate and hard-to-reach areas of the mold. The ultrasonic energy enhances the polishing action and allows for better control and precision.Fluid Mold Polishing

Fluid polishing, also known as abrasive flow machining, involves the use of a viscous abrasive media that is forced through the mold cavities and cores under pressure. The abrasive particles in the fluid flow help remove imperfections and polish the mold surfaces. This method is suitable for achieving consistent and uniform polishing on complex mold geometries.Magnetic Mold Polishing

Magnetic polishing utilizes a mixture of abrasive particles and a magnetic field to polish the mold surfaces. The mold is placed in a container with the abrasive media, and the magnetic field induces movement and agitation of the particles against the mold surface, resulting in polishing and smoothing.How to Choose Suitable Injection Mold Polishing?

As we mentioned above, each mold polishing method has its advantages and suitability for specific mold materials, shapes, and desired finishes. It is important to choose the appropriate method and right mold surface textures. What factors should be considered when we make the selection? Here are some suggestions.Mold Material:

Consider the type of material used for the mold, such as steel, aluminum, or plastic. Different materials may require specific polishing methods to achieve the desired finish without causing damage.Mold Complexity

Evaluate the complexity of the mold design, including intricate details, thin walls, and complex geometries. Some polishing methods may be better suited for reaching difficult-to-access areas or polishing intricate features.Surface Finish Requirements

Determine the desired surface finish for the molded parts. If a high-gloss, mirror-like finish is required, a combination of mechanical and chemical polishing methods may be appropriate. For less critical applications, a simpler polishing method may be sufficient.Time Constraints

Consider the project timeline and available resources. Some polishing methods may require more time and labor-intensive processes, while others offer quicker results. Balance the need for speed with the desired level of quality.Cost Considerations

Evaluate the cost-effectiveness of different polishing methods. Some techniques, such as ultrasonic or electrolytic polishing, may involve higher equipment and material costs. Assess the budget and weigh the benefits of each method against the associated expenses.

Zhongde Custom Mold Design and Manufacturing

Plastic Injection Mold Polishing Tips

Follow these tips to maximize the effectiveness of injection mold polishing:- Pre-polishing Preparation: Before machining a new mold cavity, carefully inspect and thoroughly clean the workpiece surface. Use kerosene or a specialized solvent to remove any dirt and ensure effective cutting with the oilstone.

- Polishing Sequence: Always start with the most challenging areas, such as deep holes and corners, and gradually work your way down to the sides and flat surfaces.

- Component Preparation: For multi-component molds, it’s recommended to polish each component individually before assembly to ensure a comprehensive and uniform surface finish.

- Surface and Edge Preparation: On wide or flat workpieces, use an oilstone to remove rough lines. Use a straight steel plate to check for undercuts and unevenness to ensure smooth demolding.

- Tool Control: Keep the oilstone handle level while polishing to avoid excessive pressure or steep angles that may cause new scratches.

- Edge Protection: Tape sandpaper or a saw blade to the edges where they intersect adjacent surfaces for optimal protection.

- Tool and Consumable Matching: Mold polishing tools (such as bamboo or copper presses) should be slightly larger than the sandpaper to ensure even pressure.

- Shape Matching: The shape of the polishing tool should closely match the mold geometry to prevent deformation during the polishing process.

- Abrasive Management: After each change of abrasive grit size, the mold surface and all tools must be thoroughly cleaned to prevent coarse particles from remaining and causing new scratches.

- Safety Protection: Always wear goggles, a mask, and gloves during polishing to protect the operator from dust and chemical solvents.