3D ABS printing unlocks a world of possibilities for creating durable, heat-resistant, and versatile components. This guide dives into the properties, advantages, and challenges of ABS 3D printing material.

What Is ABS?

Acrylonitrile Butadiene Styrene is a thermoplastic polymer, commonly referred to as ABS. Lightweight and slightly flexible, ABS is designed to endure repeated stress. It is easy to process, can be sanded and painted. ABS plastic in 3D printing is renowned for its combination of mechanical strength, toughness, and high heat resistance.

Why Choose ABS for 3D Printing?

The decision to use ABS 3D printing stems from its array of advantagesbellow:

- Unmatched Durability: ABS 3D printing material offers exceptional impact resistance and tensile strength, crafting parts that endure mechanical stress.

- Superior Heat Resistance: ABS 3D parts resist deformation up to 105°C, making them ideal for applications exposed to elevated temperatures, such as automotive components or kitchen appliances.

- Cost-Effective Solution: ABS printing is economical, offering high performance at a fraction of the cost of other engineering plastics.

- Post-Processing Versatility: ABS 3D printing material can be sanded, drilled, painted, or smoothed with acetone vapor, allowing for polished, professional-grade finishes.

- Electrical Insulation: The insulating properties of ABS plastic in 3D printing protecting sensitive components from electrical interference while maintaining structural integrity.

ABS 3D Printing Service

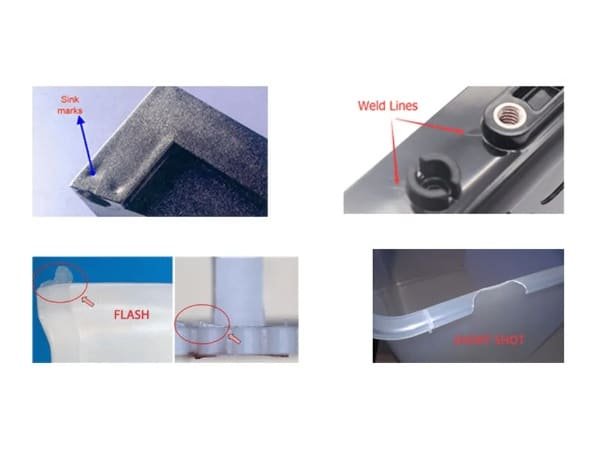

Disadvantages of ABS 3D Printing

While ABS 3D printing offers numerous benefits, it is not without its challenges, which require careful management to achieve optimal results.

- Warping and Cracking: The thermal contraction of ABS 3D printing material during cooling can cause warping, curling, or cracking, particularly in large or intricate designs.

- Toxic Fumes: When heated during ABS printing, the material emits potentially harmful fumes with a strong odor.

- Printing Complexity: ABS 3D requires advanced equipment, such as a heated bed and an enclosed chamber, to maintain consistent temperatures.

- UV Sensitivity: Prolonged exposure to sunlight can degrade ABS 3D printing material, leading to color fading or reduced mechanical properties.

- Moisture Sensitivity: ABS plastic absorbs water from the air, which can degrade print quality if not stored in a dry environment.

Requirements and Precautions for FDM 3D Printing with ABS

FDM is the most popular method for ABS 3D priting. The first, prepare a printer with a heated bed. Then setting the nozzle temperature for consistent extrusion. Prior to printing, store ABS filament in a sealed, dry container and preheat it if necessary.

ABS FDM Printing Service

Key Precautions for ABS FDM 3D Printing:

- Always print in a well-ventilated area to minimize exposure to emissions.

- Maintain a bed temperature of 95–110°C to promote adhesion and minimize shrinkage, preventing the part from lifting off the build plate.

- Use adhesives or tapes on the print bed (like glue stick, Kapton tape, or ABS slurry) to promote first-layer adhesion.

- Store ABS 3D printing material in airtight containers to prevent moisture absorption, which can lead to bubbling or poor print quality.

- Maintain stable ambient temperature and minimize airflow during prints.

- Incorporate brims or rafts in the print design to enhance bed adhesion reducing the risk of curling.

- Opt for printing speeds of 30–60 mm/s to allow layers to cool gradually, minimizing deformation and ensuring dimensional accuracy.

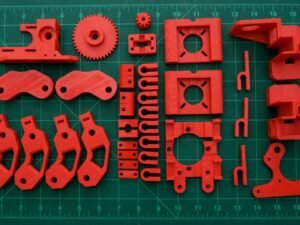

Applications of ABS 3D Printing