Improve Transmission Device Performance with High-Performance Gaskets

Introduction:

SenYuan Manufacturing, a leading provider of transmission devices, approached us, an on-demand manufacturing company, seeking to improve the quality and performance of their gaskets. They required gaskets that could withstand challenging working environments, including high temperatures, exposure to fuels and oils, and resistance to various chemicals. Our expertise in on-demand manufacturing and material selection enabled us to provide them with a tailored solution.

Challenge from Client:

SenYuan Manufacturing’s transmission devices demanded superior gaskets to ensure optimal performance and reliability. The existing gaskets were struggling to withstand the harsh operating conditions, leading to leakage and compromised performance. SenYuan Manufacturing sought a partner who could recommend the most suitable material and manufacturing process to address their gasket challenges.

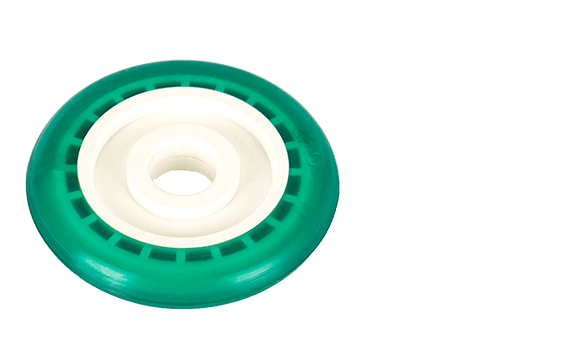

Based on our expertise and the client’s requirements, we recommended the use of Viton as the material for the gaskets. The material offered exceptional resistance to high temperatures, and exposure to fuels, oils, and chemicals commonly found in transmission devices.

We utilized compression molding, a precise and efficient manufacturing process, to produce the gaskets with consistent quality and dimensions.

Results and Benefits:

By implementing our solution, SenYuan Manufacturing experienced significant improvements in the performance and reliability of their transmission devices:

- Enhanced Sealing Performance: The fluoroelastomer gaskets provided superior sealing performance, preventing leaks and ensuring proper fluid containment within the transmission devices. This resulted in improved overall performance and minimized downtime.

- Increased Durability: The gaskets’ resistance to high temperatures, aging, weathering, and chemicals ensured a prolonged service life. This reduced the need for frequent gasket replacements, resulting in cost savings for SenYuan Manufacturing.

- Optimal Compatibility: The chosen material demonstrated excellent compatibility with fuels, oils, and various chemicals commonly encountered in transmission devices. This ensured reliable sealing without compromising the gasket’s integrity or performance.

- Customer Satisfaction: With the enhanced performance and reliability of their transmission devices, SenYuan Manufacturing achieved higher customer satisfaction. Their clients could rely on the devices for uninterrupted operation, reducing maintenance and operational costs.

Conclusion:

Through our collaboration with SenYuan Manufacturing and the implementation of fluoroelastomer gaskets, we successfully addressed their gasket challenges and improved the performance of their transmission devices. Zhongde expertise in material selection and precision manufacturing processes enabled us to provide gaskets that could withstand demanding working environments, ensuring optimal performance and durability.

This case study showcases the value of our on-demand manufacturing services in meeting specific product requirements and exceeding client expectations.

Start A New Project With Zhongde Now!

- All information and uploads are secure and confidential