A Solution for Enhancing Marine Cup Holders with HDPE in Marine Industry

Industry: Marine

Technology: Injection Molding,

Introduction:

In the competitive marine industry, our client, Oceanic Accessories, sought to elevate their cup holders’ quality and durability to meet the demanding needs of boat owners. They approached us, an on-demand manufacturing company, to collaborate on improving their cup holders. The objective was to develop a unique construction using high-density polyethylene (HDPE) material, ensuring superior performance in marine environments.

Challenge from Client:

Oceanic Accessories faced challenges in finding cup holders that could withstand harsh marine conditions, including exposure to water, UV rays, and salt. They desired cup holders with exceptional durability, resistance, and a distinctive design to set their products apart from competitors. Our task was to develop a construction solution using HDPE material that met these requirements.

To meet Oceanic Accessories’ requirements, we developed a unique construction for their cup holders utilizing HDPE material. The following features and solutions were implemented:

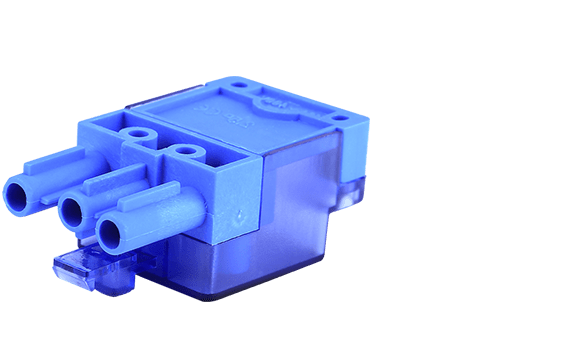

- Material Selection: After careful evaluation, we determined that HDPE material was the ideal choice for the cup holders due to its exceptional durability, resistance to water and UV exposure, and suitability for injection molding.

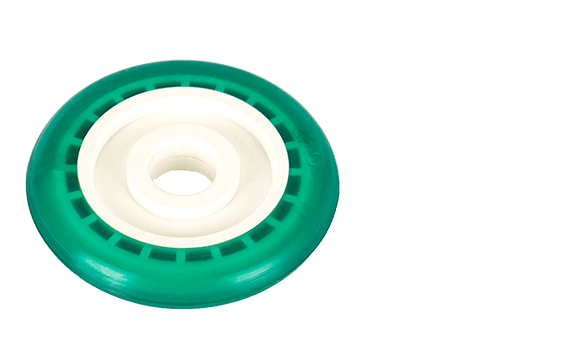

- Injection Molding: We employed the injection molding process to manufacture the cup holders. This highly efficient manufacturing method involved injecting molten HDPE material into a custom mold under high pressure. The mold was precisely designed to replicate the cup holders’ intricate features and ensure consistency in shape and dimensions.

- Customized Design: Working closely with Oceanic Accessories, we incorporated a reinforced ribbed structure within the cup holder design to enhance strength and stability. Additionally, an integrated drainage system was integrated to efficiently channel and drain water or liquid. The cup holders’ aesthetics were customizable, allowing for personalized branding elements such as color variations, embossed logos, and textured finishes.

Results and Benefits:

The collaboration between our team and Oceanic Accessories resulted in the following outcomes and benefits:

- Superior Durability and Resistance: The cup holders’ unique construction using HDPE material delivered exceptional durability and resistance to water, UV exposure, and salt. This ensured their longevity and maintained their quality even in harsh marine environments.

- Enhanced Functionality: The reinforced ribbed design provided a secure and stable grip for various cup sizes, preventing spillage and ensuring a reliable holder for beverages on boats. The integrated drainage system effectively eliminated water accumulation, enhancing user convenience and preventing potential damage.

- Customized Branding: The ability to customize the cup holders’ aesthetics allowed Oceanic Accessories to showcase its brand identity and stand out in the market. The personalized design options created a strong visual impact and increased brand recognition among boat owners and enthusiasts.

Conclusion:

Through our collaboration with Oceanic Accessories, Zhongde successfully developed a unique construction for cup holders using HDPE material, tailored to the demanding requirements of the marine industry. The cup holders’ reinforced ribbed design, integrated drainage system, and customizable aesthetics elevated their functionality, durability, and visual appeal. Oceanic Accessories gained a competitive edge in the market, offering cup holders that not only met but exceeded the expectations of boat owners. This case study demonstrates the value of our expertise in on-demand manufacturing, specifically utilizing the injection molding process and our commitment to delivering innovative solutions that enhance product quality and customer satisfaction.

Start A New Project With Zhongde Now!

- All information and uploads are secure and confidential