A Case Study on Zhongde’s Injection Molded Components for Joseph’s Communication Devices

Industry: Communication Devices

Technology: Injection Molding, Overmolding

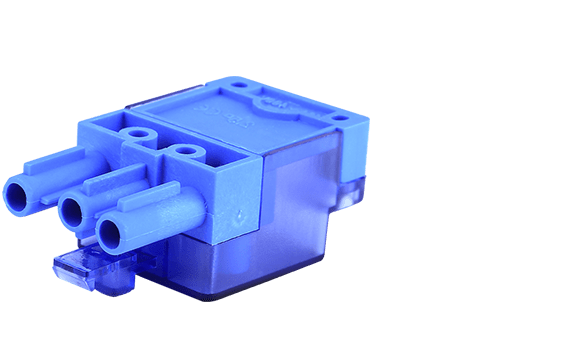

- The communication devices’ part operates in demanding environments exposed to extreme temperatures, moisture, and vibrations. They sought components that could withstand these challenging conditions while maintaining signal integrity.

- We recommend utilizing injection molding as the primary manufacturing process, combine with overmolding process. high-performance plastic part overmoled rubber layer to improve the part's sealing capabilities.

- The successful collaboration between Joseph's Communication Devices and Zhongde demonstrated the power of leveraging expertise in injection molding to overcome challenges related to signal strength and service life.

Joseph’s Communication Devices, a leading provider of communication solutions, the communication devices’ part operates in demanding environments exposed to extreme temperatures, moisture, and vibrations. They sought components that could withstand these challenging conditions while maintaining signal integrity. To address these requirements, Joseph collaborated closely with us, an on-demand manufacturer specializing in injection molding. This case study explores how Zhongde‘s expertise and innovative solutions helped Joseph improve their communication devices’ performance, service life, and overall cost-effectiveness.

Based on the working environment conditions and requirements, we recommend utilizing injection molding as the primary manufacturing process for producing the communication device part. High-performance plastics like PEEK, PAI, or PPS can be selected based on the specific mechanical, thermal, and chemical resistance properties required.

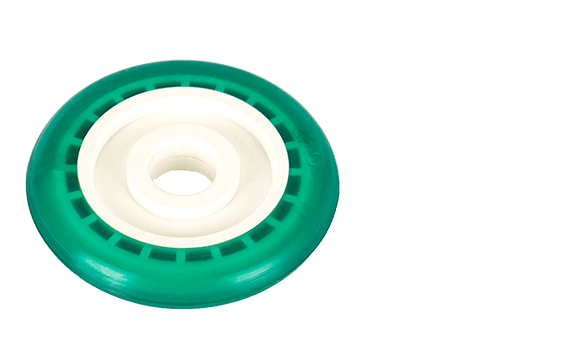

To enhance the part’s performance and resistance to moisture, extreme temperatures, and vibrations, an overmolding process can be employed. This involves using silicone rubber as a secondary material to encapsulate or provide specific features to the high-performance plastic part. The overmolded silicone rubber layer will improve the part’s sealing capabilities, flexibility, and resistance to moisture and vibration.

By combining these materials and manufacturing processes, we can create a communication device part that excels in demanding environments. The high-performance plastics will ensure strength, dimensional stability, and resistance to extreme temperatures and chemicals, while the silicone rubber overmolding will provide enhanced moisture resistance, flexibility, and vibration-damping properties.

The successful collaboration between Joseph’s Communication Devices and Zhongde demonstrated the power of leveraging expertise in injection molding to overcome challenges related to signal strength and service life. By analyzing and optimizing the injection molded components, integrating advanced materials, and closely aligning with Joseph’s requirements, Zhongde helped Joseph improve their communication devices’ reliability, durability, and performance. The result was a competitive advantage in the market, increased customer satisfaction, and substantial cost savings.

This case study serves as a testament to the benefits of collaboration and innovation in addressing complex engineering challenges and achieving business success.