In the daily production of modified plastic injection molding, some problems are likely to occur. The more common defects mainly include dark spots, gloss differences, and surface wrinkles (also known as orange peel). Generally speaking, these defects are often Occurs near the gate, so today we will analyze the causes of the defects from the mold and molding process.

Gloss difference

For injection molding plastic products, the difference in gloss on the surface of the textured product is most obvious. Even if the surface of the mold is very uniform, an irregular gloss may appear on the product. That is to say, the mold surface effect of some parts of the product is not well reproduced.

As the distance of the melt from the gate gradually increases, the injection pressure of the melt gradually decreases. If the distal end of the gate of the product cannot be filled, the pressure there is the lowest, so that the texture of the mold surface cannot be correctly copied to the surface of the product. Therefore, the area where the cavity pressure is the greatest (half of the fluid path from the gate) is the area where the gloss difference is the least.

To change this situation, you can increase the melt and mold temperature or increase the pressure, while increasing the holding time can also reduce the difference in gloss.

Good design of custom plastic parts can also reduce the chance of gloss differences. For example, drastic changes in the wall thickness of the product can cause irregular flow of the melt, which makes it difficult for the surface texture of the mold to be copied to the surface of the product. Therefore, the design of uniform wall thickness can reduce the occurrence of this situation, and excessive wall thickness or excessive ribs will increase the chance of gloss difference. In addition, insufficient venting of the melt is also a cause of this defect.

Dark spots

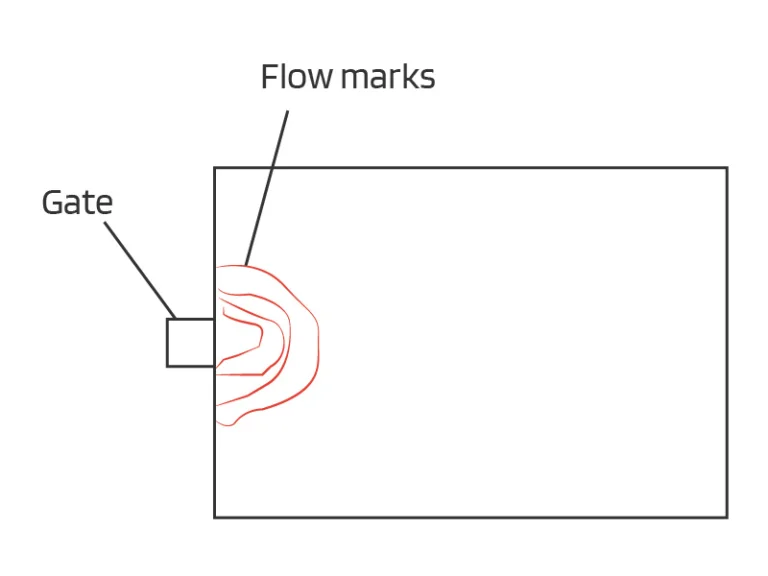

Dark spots appear near the gate, like a dim halo. It is especially obvious when producing plastic products with high viscosity and low fluidity materials, such as PC, PMMA, or ABS. When the cooled surface layer resin is taken away by the center-flowing resin, such visible defects may appear on the surface of the product.

It is generally believed that such defects frequently occur in the filling and holding pressure stages. In fact, dark spots appear near the gate, usually at the beginning of the injection cycle. Experiments show that the occurrence of surface slip is actually due to the injection speed, more precisely the flow speed at the front end of the melt flow.

The dark spots around the gate and the dark spots that appear after the formation of a sharp corner are caused by the initial injection speed being too high, and the cooling surface is displaced by the internal fluid. Increasing the injection speed gradually and injecting it step by step can serve this defect.

Even if the injection speed of the melt is constant when it enters the mold, its flow speed will change. When entering the mold gate area, the melt flow rate is very high, but after entering the mold cavity, that is, the filling stage, the melt flow rate begins to decrease. This change in the velocity of the front end of the melt flow can cause defects on the surface of the product.

Reducing the injection speed is one way to solve this problem. In order to reduce the speed of the front end of the melt flow at the gate, the injection can be divided into several steps and the injection speed is gradually increased. The purpose is to obtain a uniform melt flow rate throughout the filling stage.

Low melt temperature is another cause of dark spots on plastic products. Increasing the barrel temperature and screw back pressure can reduce the probability of this phenomenon. In addition, the temperature of the mold is too low to cause surface defects, so increasing the mold temperature is another feasible way to overcome the surface defects of the product.

Mold design defects can also produce dark spots near the gate. Sharp corners at the gate can be avoided by changing the radius. Pay attention to the position and diameter of the gate during design to see if the gate design is appropriate.

Dark spots not only occur at the gate location but also often appear after sharp corners of custom plastic injection molding products are formed. For example, the sharp corner surface of an article is generally very smooth, but behind it is very dull and rough. This is also caused by the excessively high flow rate and injection speed causing the cooling surface layer to be replaced by internal fluid and sliding.

It is again recommended to use step injection and gradually increase the injection speed. The best method is to allow the melt to only start to increase in velocity after it has flowed over the sharp edge.

In the area far from the gate, sharp changes in the angle of the product can also cause this defect. Therefore, when designing products, it is necessary to use smoother rounded transitions in those areas.

Orange peel

“Orange peel” or surface wrinkling defects generally occur at the end of the runner when a thick-walled product is molded with a high-viscosity material. During the injection process, if the melt flow rate is too low, the surface of the plastic product will quickly solidify. As the flow resistance increases, the front flow of the melt will become uneven, so that the first solidified outer layer material cannot fully contact the cavity wall, resulting in wrinkles.

These creases become indelible defects after curing and holding pressure. For this defect, the solution is to increase the melt temperature and increase the injection speed.