Polypropylene(PP) polymer is made from propylene through the polymerization reaction. It is a thermoplastic with excellent performance. PP is colorless, semi-transparent, and famous for its tough and flexible properties. Polypropylene plastic has been used to manufacture plastic parts in various industries, and polypropylene injection molding is the most popular manufacturing process.

What is PP Injection Molding?

Similar to the common injection molding process, PP injection molding generally involves several key steps. First, PP pellets are dried if necessary and fed into the hopper of the injection molding machine. They are then heated and melted in the barrel, where the screw conveys the molten material forward. Next, the molten PP is injected into the mold cavity under high pressure. Once the material fills the cavity, it is held under pressure to compensate for shrinkage during cooling. After sufficient cooling time, the mold opens and the solidified PP part is ejected. The mold then closes again, and the cycle repeats for continuous production.

Types of Polypropylene Injection Molding Material

Polypropylene can be categorized into 2 types: homopolymers and copolymers. It’s important to understand the different types of PP plastics. Each type can be applied to different applications.

Homopolymer Polypropylene

Homopolymer polypropylene, also known as PPH, is the common state of PP plastic. It is also considered to be a general-purpose-grade plastic. PPH can be divided into the following three categories.

- Isotactic PP: it accounts for about 95% of PP production.

- Intercalated PP: it has low crystallinity. It is a highly elastic thermoplastic or elastomer.

- Irregular PP: its strength is very low, and its use alone is of little value, but it works well as a modifier for polypropylene, etc.

Copolymer Polypropylene

Copolymer PP can be divided into random copolymer and block copolymer.

- The random copolymer has better optical transparency, flexibility, lower melt finger temperature, and high impact resistance. It is usually used in manufacturing highly transparent film, water, and sewage pipes, heating pipes, and injection molding products.

- Block copolymer has better rigidity and low-temperature toughness.

PP Material Free Selection Service

Advantages of Polypropylene Injection Molding Material

- Low Cost: PP is easy to access and not expensive. After polyethylene, polypropylene is the most widely used plastic, so is relatively inexpensive compared to other types of thermoplastics.

- High Flexural Strength and Resistance Impact: PP has a high flexural strength by virtue of its semi-crystalline property.

- Low Coefficient of Friction: PP has a relatively slippery surface. The slippery surface makes PP has a lower coefficient of friction. That characteristic facilitates the release of injected molded parts from tooling, which helps to speed cycle times and reduce overall costs.

- Resistant to Moisture Absorption: Polypropylene has excellent moisture resistance and the water absorbs less than 0.01% over 24 hours.

- Good Chemical Resistance: Polypropylene resists a wide range of chemicals, including fats, organic solvents, and some non-oxidizing acids.

- Resistant to Fatigue: With excellent fatigue resistance, polypropylene is commonly used in a living hinge. A living hinge is a part that supports bending.

- Great Electrical Insulator: Polypropylene does not conduct electricity well. These properties make it an excellent material for manufacturing electronic components.

Disadvantages of Polypropylene Injection Molding Material

- Limits to High Temperature: Polypropylene has limited use in high temperatures as it has a high thermal expansion coefficient.

- Sensitive to UV: PP plastic is UV-sensitive and susceptible to oxidation.

- Not Resistant to Chlorinated Solvents and Aromatics: Though polypropylene has good chemical resistance, but it has poor resistance to chromic acid and aromatic hydrocarbons.

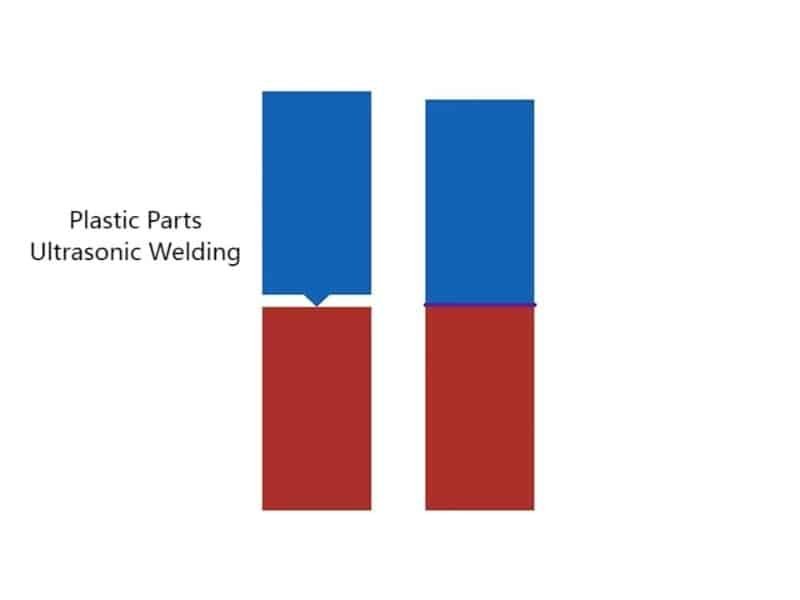

- Not Easy to Bonding with Other Materials: Polypropylene has poor bonding properties, so it is hard to paint on polypropylene.

- Highly Flammable: Polypropylene is extremely flammable and will melt when exposed to heat. the melt temperature is just 260℃.

Polypropylene Properties

Following are the general parameters of pp injection molding material. The data can be difference between different types of polypropylene materials.

| Property | Value |

|---|---|

| Density (g/cm³) | 0.895- 0.92 |

| Shrinkage Rate (%) | 1.0 – 3 |

| Pockwell Hardness | R80 – R125 |

| Tensile Strength at Yield (MPa) | 20 – 40 |

| Elongation at Break (%) | 200 – 600 |

| Flexural Modulus (GPa) | 1.0 – 1.5 |

| Flexural Strength (MPa) | 30 – 50 |

| Drying Temperature (°C) | 70 – 80 |

| Melt Temperature (°C) | 220– 280 |

| Mold Temperature (°C) | 20 – 80 |

Polypropylene Injection Molding Parameters

PP Material Drying

PP has excellent resistance to moisture absorption. Different from ABS plastic injection molding, PP does not need to be dried before injection molding.

PP Injection Molding Pressure

The pp injection molding pressure should be as high as 180MPa. It’s important to note that while higher injection pressure produces favorable results, excessively high pressures can result in the part sticking to the mold.

PP Melting Point

PP plastic melting temperature is between 220 – 280℃ / 428 – 536℉. The pp injection molding temperature should not be higher than 280℃ / 536℉, or the material will be thermal degradation.

PP Mold Temperature

The pp mold temperature can vary between 20 – 80℃ / 68 – 176℉. The suggested temperature is 50℃ / 122℉. The polypropylene mold temperature is the factor that determines the PP plastic’s crystallinity level.

The Cooling Temperature for PP

After injection, the polypropylene molded part should be cooled to 54°C before ejection from the mold cavity to prevent warping.

PP Injection Molding Speed

For the PP injection molding process, it is recommended that the injection molding speed is fast enough so that to keep the internal stresses at the lowest possible level.

PP Mold Runners and Gates Parameter

The full-round sprues and runners are usually recommended. The common diameter should be between 4-7mm for cold runner molds. Usually, the diameter of a pin gate is between 1-1.5mm. But it can also be as low as 0.7mm.

In the case of edge gating, the depth of the gate should be kept higher than half of the wall thickness, and the wide is at least twice the thickness. The hot runner molds can be used for the PP injection molding directly.

Shrinkage Range

The polypropylene injection molding parts’ average shrinkage rate is between 1% and 3%. Filled polypropylene can have lower shrinkage values, the values depend on the fill material that is used.

PP Injection Molding Design Guidelines

When designing parts for injection molding, following proper guidelines helps ensure manufacturability, cost efficiency, and product performance. Key considerations include:

Wall Thickness: Keep the wall thickness as even as possible. For PP, around 1.5–3.5 mm works well. Sudden changes cause warpage or sink marks, so smooth transitions are better.

Draft Angles: Always add a draft for easy part release. About 1–2° per side is enough for PP, but go higher if the surface has texture or the part is deep.

Ribs and Bosses: Use ribs to add strength instead of making walls too thick. Ribs should be about half the wall thickness, and bosses should be reinforced with ribs to avoid sink marks.

Corners and Radii: Avoid sharp corners; PP doesn’t like them. Adding generous radii helps the material flow, reduces stress, and makes the part more durable.

Applications of Polypropylene Injection Molding

Polypropylene (PP) is a common manufacturing plastic material and is used in a wide range of applications in daily life.

- Plastic parts for the automobile industry

- Special devices like living hinges

- Medical instruments

- Textiles materials

- Toys and consumer products

- food packaging

Conclusion with PP Injection Molding

Polypropylene is a commonly used plastic injection molding service, it is not expensive and easy to get. In the PP material selection and injection molding process, it is important to cooperate with Zhongde and to ensure the project runs smoothly. Zhongde is a professional on-demand manufacturer with a 40-year history. Our production and material experts will support your project and get quality injection molded parts.